Nexturn SA(PII) Series – 7-Axis Swiss Lathes with Exchangeable Guide Bushings

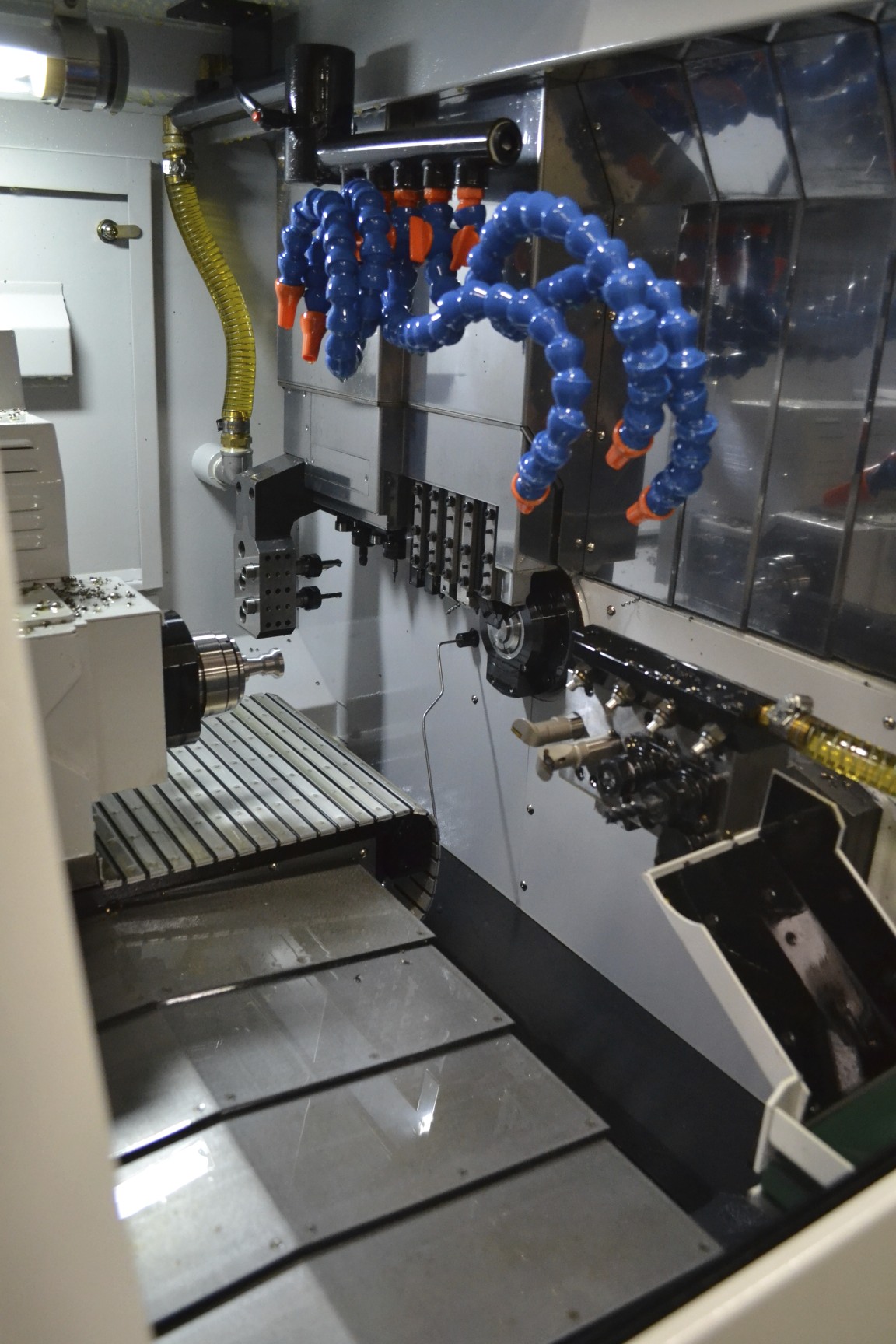

The Nexturn SA(PII) Series of high precision CNC Swiss type automatic lathes are engineered for exceptional accuracy, stability, and productivity in today’s high-demand precision turning environments. Available in 20mm (0.787″), 32mm (1.26″), and 38mm (1.496″) bar capacities, these 7-axis CNC Swiss machines—with or without rotary synchronous guide bushings—deliver outstanding results for medical, aerospace & defense, automotive, electronics, and general small-parts production.

Designed to compete with top brands such as Marubeni Citizen-Cincom, Star, Tornos, Hanwha, Doosan, Mazak, Swiss-Tech, and Swissturn, the SA(PII) Series combines precision engineering with premium Japanese and German components—including Fanuc CNC controls and motors, NSK ballscrews and bearings, THK linear guideways, FAG bearings, and KHK gears—to ensure world-class rigidity, repeatability, and reliability.

Key Features

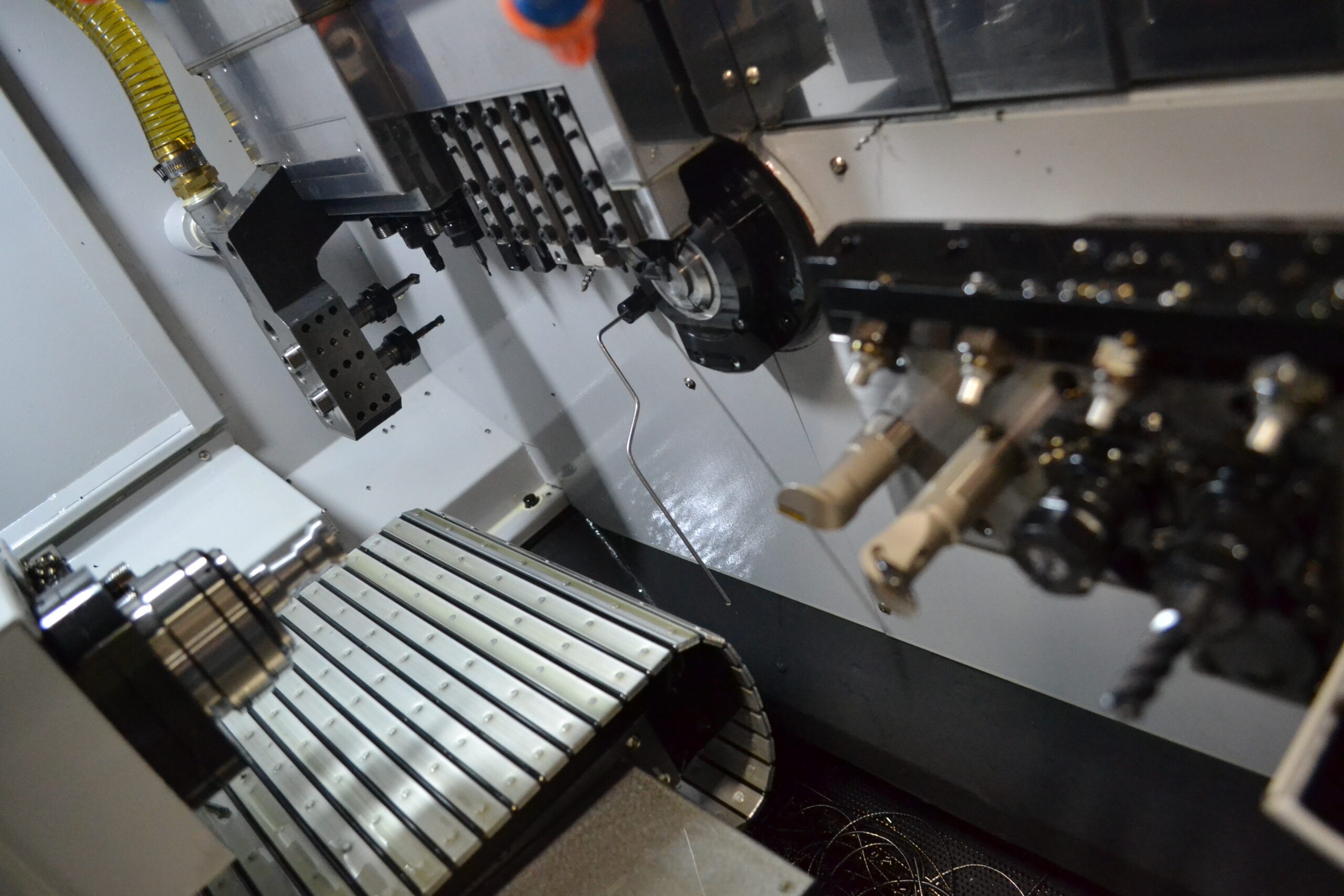

- Axes: 7 total (Z1, X1, Y, Z2, X2, C1, C2)

- Tooling Capacity: Up to 20–23 total tools depending on configuration

- Spindles:

- Main spindle: Built-in motor (5–10 HP, up to 10,000 RPM) with 0.001° Cs-axis positioning

- Sub spindle: Built-in or belt-drive motor (3–5 HP, up to 8,000 RPM) with full Cs-axis control

- Machining Capacities:

- Maximum bar turning diameter: 20mm (0.787″) – 38mm (1.496″)

- Maximum turning length: 250mm (9.84″)

- Maximum drilling/tapping: 12mm (0.472″) / 10mm (0.394″)

- Maximum disc-mill diameter: 40mm (1.57″)

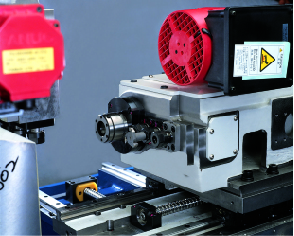

- Live Tooling:

- Cross-mill units up to 6,000 RPM

- Back-end live tools up to 5,000 RPM

- ER-16 collet system and rigid tapping standard

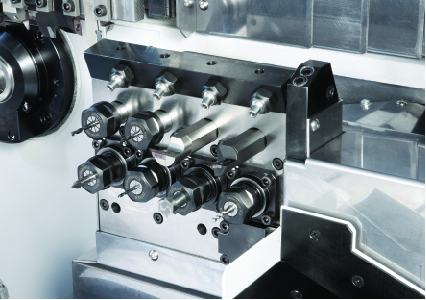

- Modular Rotary Spindle Options: Optional WTO modular ER-16 rotary spindles for cross, front, or back working positions allow quick setup changes and tooling flexibility. These high-precision modular units improve rigidity, reduce vibration, and expand multi-axis milling, drilling, and tapping capabilities.

- Guide Bushing System: Optional rotary synchronous guide bushing with dual-bearing, spline-driven design ensures superior support and concentric accuracy.

- Machine Construction: One-piece Meehanite cast-iron bed with FEM-optimized ribbing for maximum stiffness and vibration damping.

- Feedrates: Rapid traverse 1,260 IPM (32 m/min); cutting feedrate 0.039–236 IPM (1–6,000 mm/min).

- Coolant & Power: 75-gallon (284L) coolant tank, inverter-driven pump, 208/220V 3-phase power.

- Machine Weight: 7,260–7,920 lbs (3,293–3,593 kg) depending on configuration.

- Control System: Fanuc 0iT-F Plus dual-path conversational control with Ethernet, USB, and Manual Guide i options.

- Automation Ready: Fully compatible with TRACER bar feeders, A+ Automation OB7 collaborative robots, Fanuc CRX cobots, Mitsubishi LoadMate Plus, and OEE DataXchange monitoring for lights-out productivity.

Specifications

| Item / Model |

SA-20PII

Request a Quote |

SA-32PII

Request a Quote |

SA-38PII

Request a Quote |

|---|---|---|---|

|

FREE TRACER 20 Bar Feeder |

FREE TRACER 32V Bar Feeder |

FREE TRACER 51V Bar Feeder Package | |

|

Number of Axes |

7 |

7 |

7 |

|

Number of Channels |

2 |

2 |

2 |

|

Bar Capacity (Front/Rear) |

20 mm / 20 mm |

32 mm / 32 mm |

38 mm / 38 mm |

|

Guide Bushing Type |

Synchronous |

Synchronous |

Synchronous |

|

Main Spindle |

5 HP / 10,000 RPM |

10 HP / 8,000 RPM |

10 HP / 8,000 RPM |

|

Sub Spindle |

3 HP / 8,000 RPM |

5 HP / 8,000 RPM |

5 HP / 8,000 RPM |

|

Max. Turn Length |

10″ |

10″ |

10″ |

|

Total Tools |

23 |

20 |

19 |

|

Fixed Tools (Front/Rear) |

12 / 3 |

12 / 2 |

11 / 2 |

|

Live Tools (Front/Rear) |

6 / 2 |

4 / 2 |

4 / 2 |

|

Live Tools |

3 HP / 6,000 RPM |

3 HP / 6,000 RPM |

3 HP / 6,000 RPM |

|

B Axis |

N/A |

N/A |

N/A |

|

C Axis Contouring |

Main/Sub |

Main/Sub |

Main/Sub |

|

CNC Control |

FANUC OiTF |

FANUC OiTF |

FANUC OiTF |

|

Weight |

7,260 lbs. |

7,700 lbs. |

7,920 lbs. |

Benefits for Metal Cutting and Parts Manufacturers

The Nexturn SA(PII) Series provides manufacturers with superior performance and flexibility for a wide range of materials and part complexities.

- Exceptional rigidity and stability: One-piece cast-iron bed designed with FEM analysis minimizes vibration and ensures high-accuracy machining.

- High-speed performance: Rapid traverse rates up to 1,260 IPM (32 m/min) and high-torque spindles reduce cycle times while maintaining ultra-fine surface finishes.

- Dual-spindle machining: Independent main and sub-spindle control allows simultaneous front and back working, dramatically improving productivity.

- Precision and accuracy: Pre-tensioned ballscrews and precision linear motion guideways maintain micron-level repeatability during long production runs.

- Thermal stability: Inverter-driven spindle oil cooling maintains consistent cutting accuracy and thermal balance.

- Ease of operation: The sliding operator door provides clean, ergonomic access, while the Fanuc 0iT-F Plus dual-path control simplifies programming and setup.

These machines enable faster cycle times, superior part finishes, and long-term reliability — ideal for industries where tolerances, speed, and consistency are mission-critical.