Quicktech T6 Series – T6 Compact (2-Axis), T6 Mill (3-Axis) Mill-Turn Centers

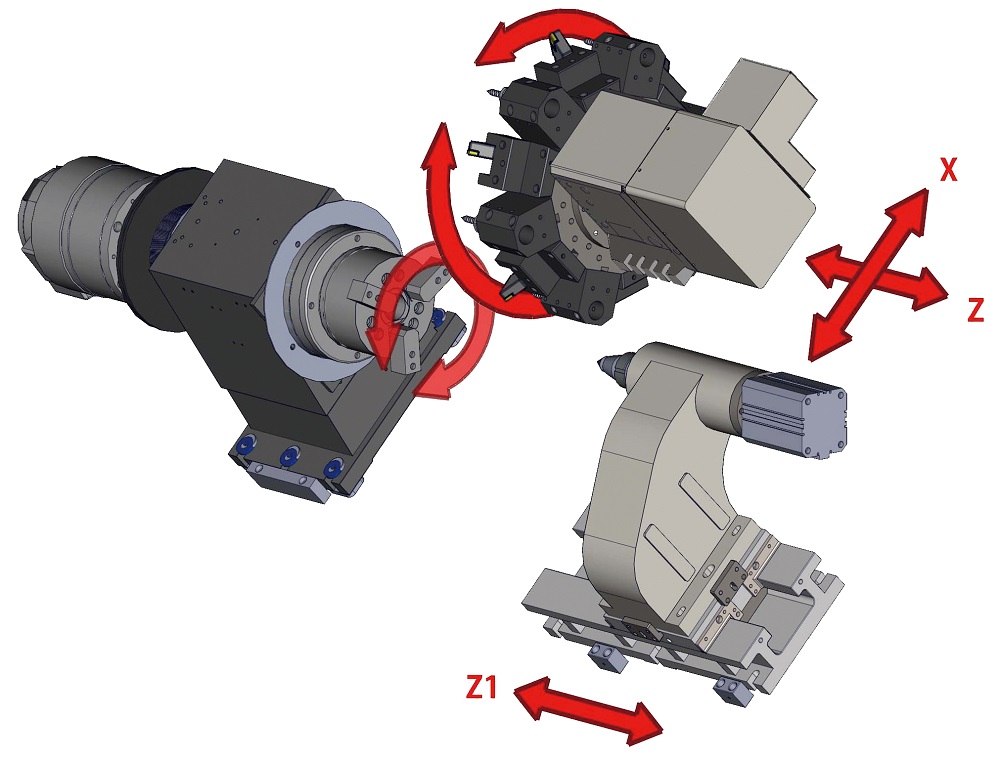

The Quicktech T6 Series combines precision, rigidity, and efficiency in a compact horizontal slant-bed design. Available in 2-axis (T6 Compact) and 3-axis (T6 Mill) configurations, these high-performance turning centers deliver exceptional accuracy and productivity in a small footprint. Each machine is cast from high-quality Meehanite iron and engineered with a one-piece 45° slant bed for outstanding rigidity and vibration control. Ideal for automotive, medical, electronics, and general job-shop manufacturers, the T6 Series offers superior performance and value compared to competitors such as Haas, Doosan, DMG Mori, and Mazak.

Key Features

- Compact 45° Slant-Bed Construction: Maximizes rigidity, chip evacuation, and operator accessibility while minimizing floor space requirements.

- Heavy-Duty Meehanite Cast Frame: One-piece casting resists thermal deformation and dampens vibration for precision turning and milling.

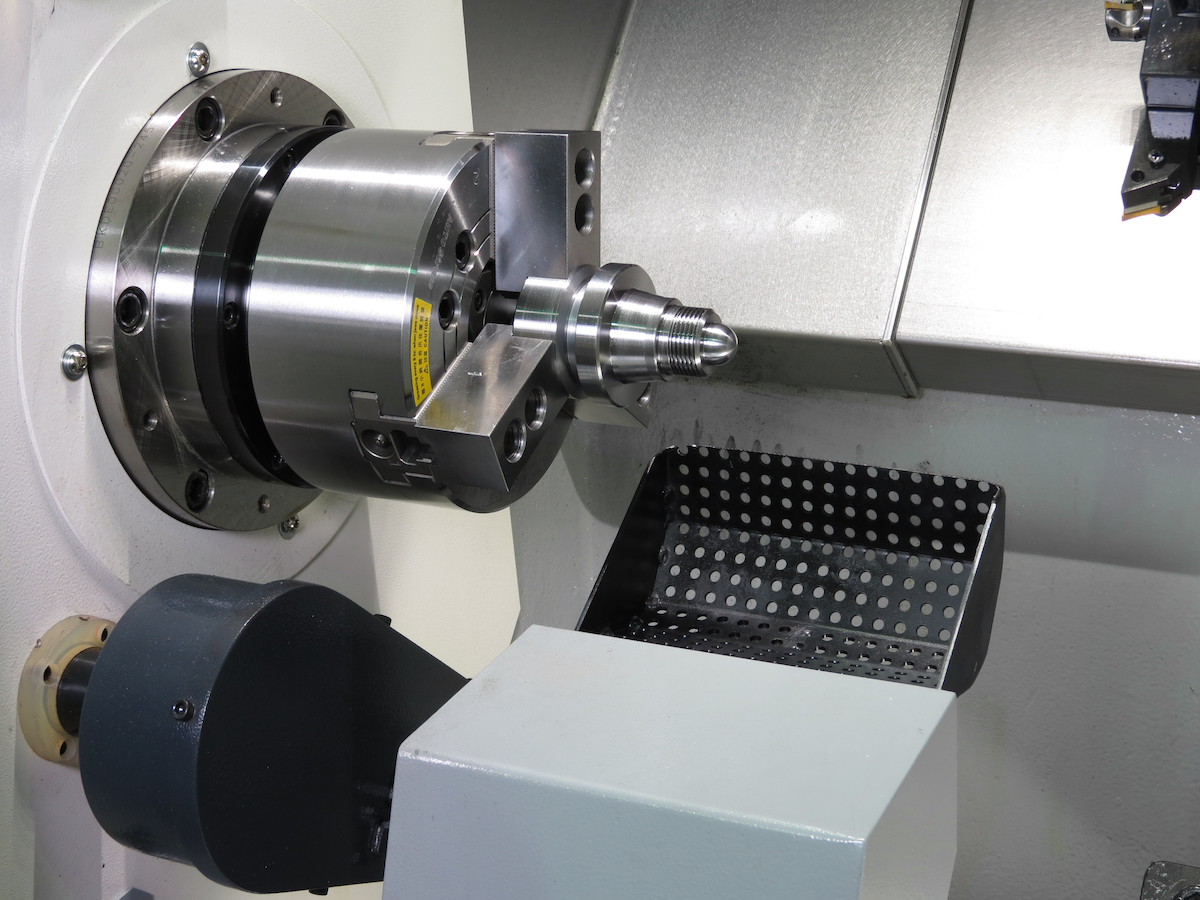

- High-Torque Main Spindle: 15 HP spindle with 1.65″ (42 mm) bar capacity and up to 6,000 RPM for smooth, efficient material removal.

- Advanced Tooling System:

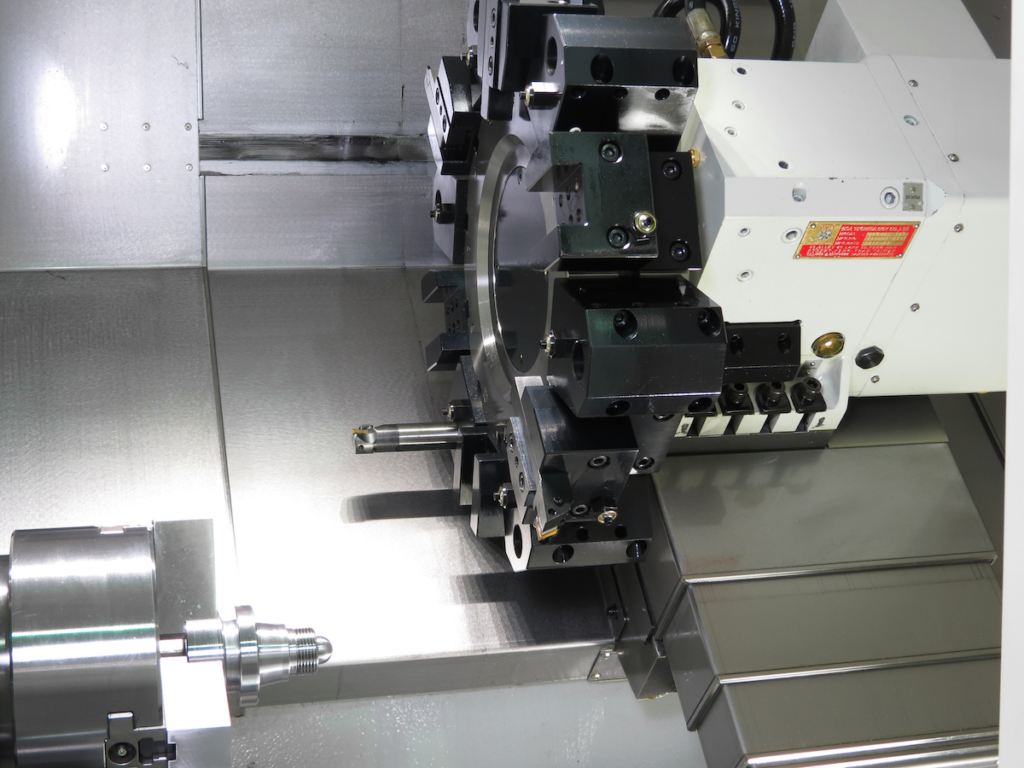

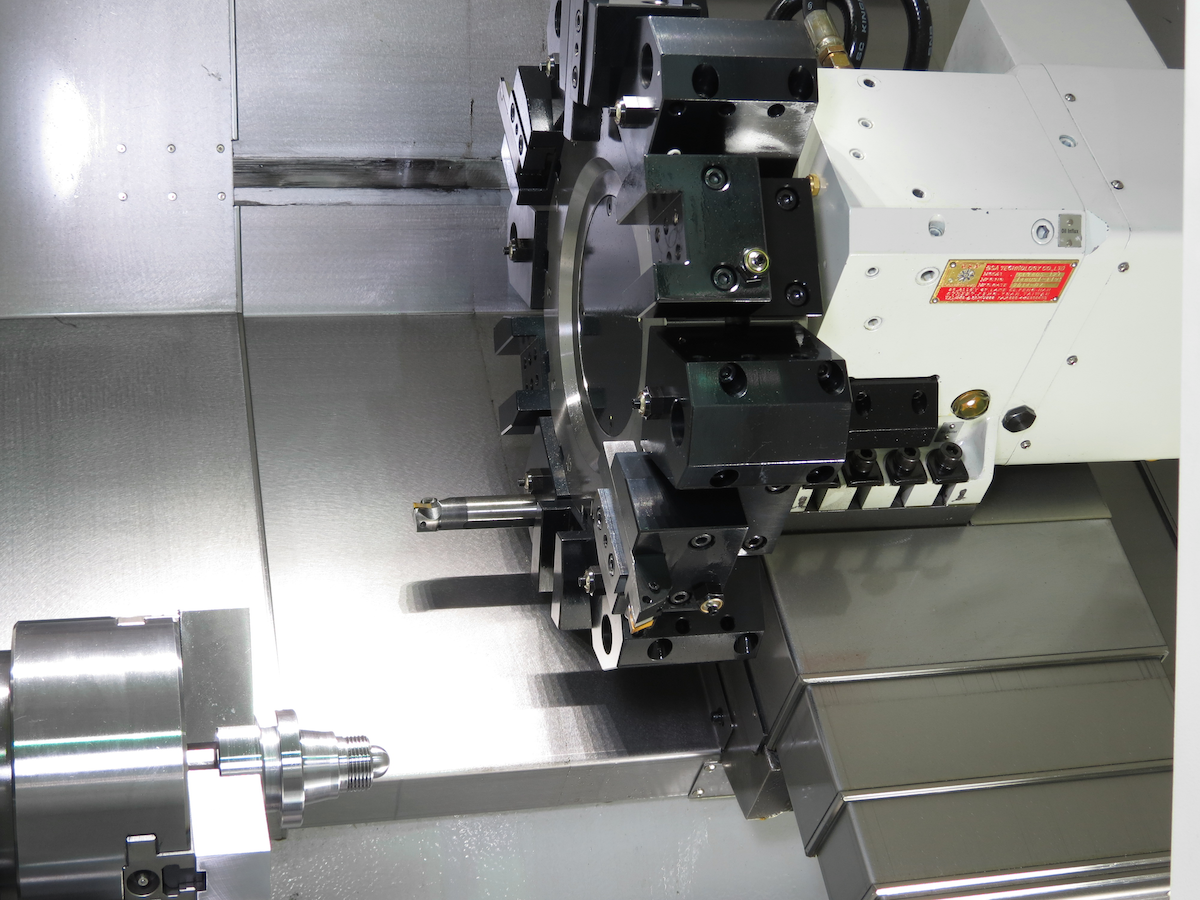

- Equipped with a rigid 12-station BMT-55 servo turret featuring fast servo indexing and hydraulic clamping for outstanding repeatability and stiffness.

- On the T6 Mill, all 12 stations are live-tool capable, powered by a 5 HP spindle motor for accurate milling, drilling, and tapping operations.

- Rigid tapping comes standard on live-tool models, while both configurations support a wide variety of OD and ID static tools for turning applications.

- Precision Linear Motion System: Oversized 35 mm roller-type linear guideways and pre-tensioned 32 mm ballscrews ensure smooth, backlash-free axis travel.

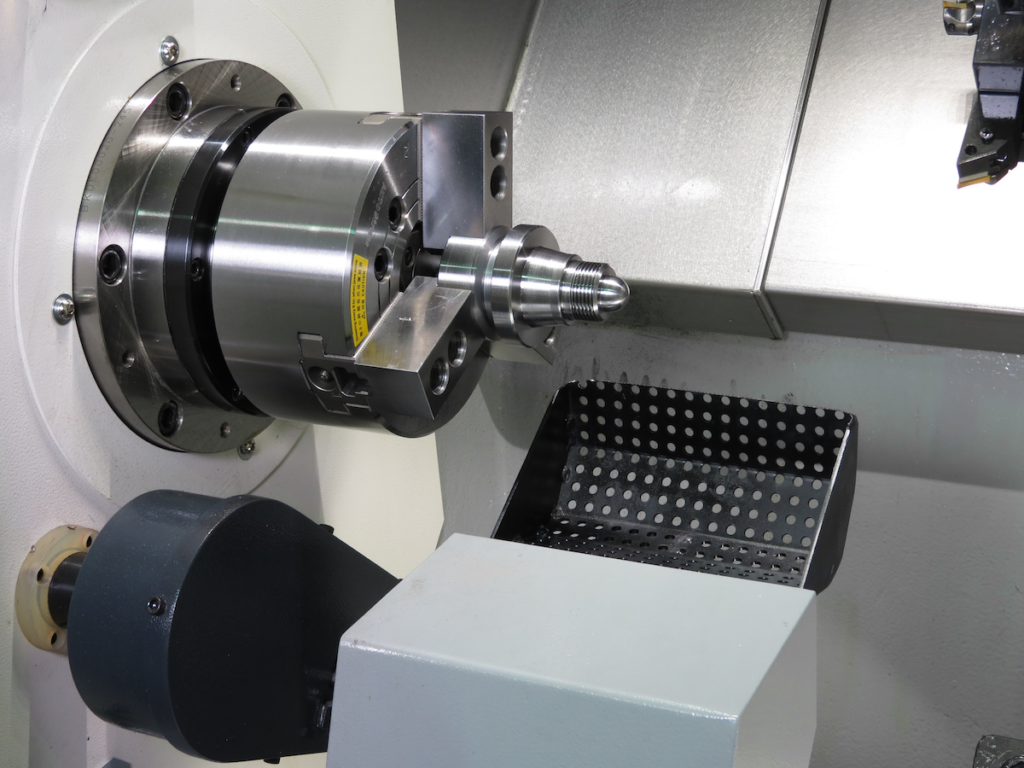

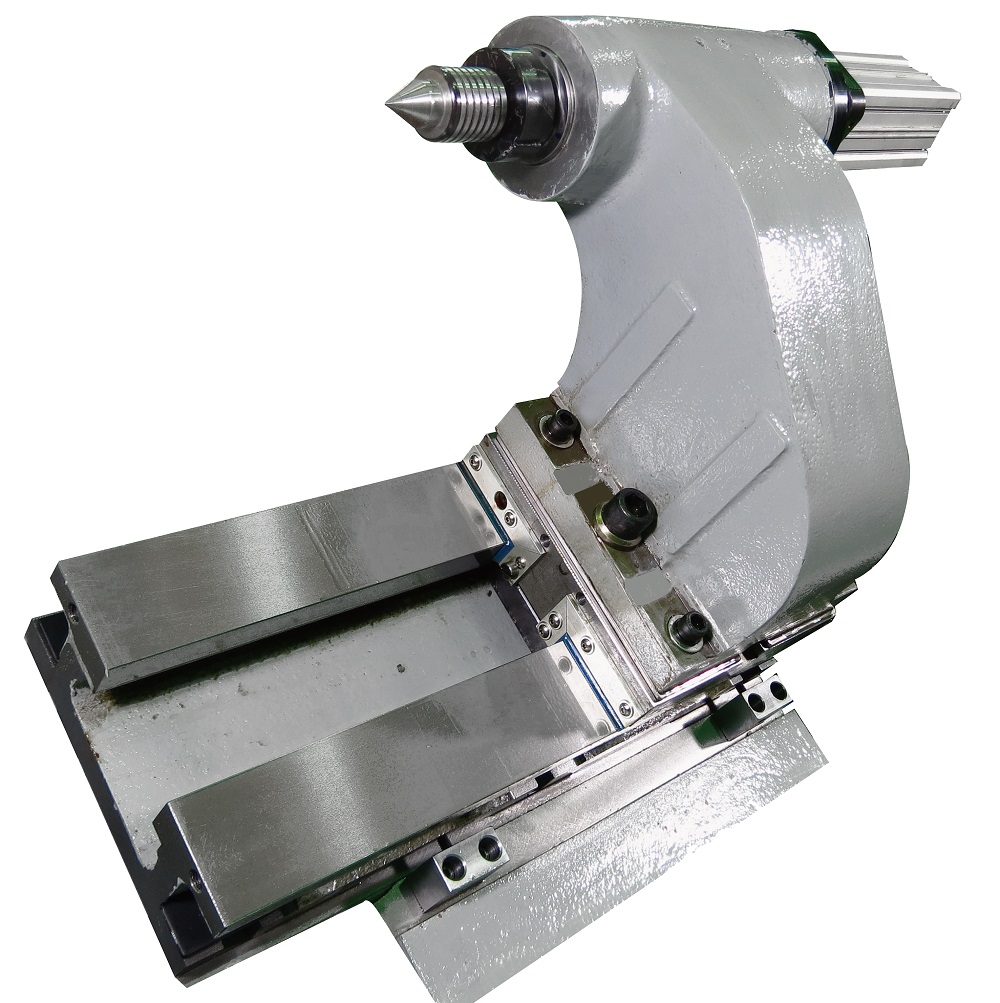

- Tailstock for Support and Stability: Hydraulic programmable quill provides reliable part support during longer workpiece operations.

- Advanced CNC Controls: Standard Mitsubishi M80A with 10.4″ touchscreen and optional Fanuc Oi-TF Plus with Manual Guide i for flexible programming and diagnostics.

- Production-Ready Configuration: Includes 6″ hydraulic chuck, chip conveyor, parts catcher, coolant pump, and bar feeder interface for seamless automation integration.

Specifications

| Item / Model |

T6 COMPACT

Request a Quote

|

T6 MILL

Request a Quote

|

|---|---|---|

|

Main Spindle Capacity | ||

|

Swing over Bed |

15.7″ |

15.7″ |

|

Swing over Cross Slide |

9.05″ |

9.05″ |

|

Max Bar Working Capacity |

1.65″ (42mm) |

1.65″ (42mm) |

|

Max Turning Length |

11.8″ |

11.8″ |

|

Spindle Speed Range |

6,000 RPM |

6,000 RPM |

|

Spindle Motor |

15 HP |

15 HP |

|

C-Axis Increment |

.001° | |

|

Sub-Spindle Capacity | ||

|

Chuck Type | ||

|

Max Bar Working Capacity | ||

|

Spindle Nose | ||

|

Spindle Speed Range | ||

|

Spindle Motor | ||

|

C-Axis Increment | ||

|

Travel and Feed | ||

|

Rapid Traverse Rate |

1,181″/min. |

1,181″/min. |

|

Tooling System (Main) | ||

|

Tooling Type |

BMT-55 Servo Turret |

BMT-55 Servo Turret |

|

Number of Tools |

12 |

12 |

|

Number of Live Tool Stations |

12 | |

|

Square Shank Size |

1″ (25mm) |

1″ (25mm) |

|

Boring Bar Capacity |

1.25″ (25mm) |

1.25″ (25mm) |

|

Turret Index Time |

.3 Seconds / Station |

.3 Seconds / Station |

|

Live Tool Spindle Motor |

5HP | |

|

Live Tool Spindle Speed |

4,000 RPM | |

|

Tooling System (Sub) | ||

|

Tooling Type | ||

|

Number of Turning Tools | ||

|

Square Shank Size | ||

|

Boring Bar Capacity | ||

|

B-Axis | ||

|

B-Axis Index Time | ||

|

Number of Live Tools | ||

|

Live Tool Spindle Motor | ||

|

Live Tool Spindle Speed | ||

|

Live Tool Shank | ||

|

Tailstock | ||

|

Body Travel (manual) |

15.7″ |

15.7″ |

|

Quill Travel (programmable hydraulic) |

3.15″ |

3.15″ |

|

Quill Diameter |

2.95″ |

2.95″ |

|

Quill Taper |

MT#4 |

MT#4 |

|

General | ||

|

CNC Control |

Mitsubishi M80A |

Mitsubishi M80A |

|

Machine Dimensions with Chip Conveyor |

126″ x 52″ x 73″ |

126″ x 52″ x 73″ |

|

Machine Weight |

9,900 lbs. |

9,900 lbs. |

Benefits for Metal Cutting Manufacturers

Quicktech’s T6 Series helps manufacturers achieve faster cycle times and higher-quality parts through efficient multitasking capabilities. The machines’ rigid Meehanite construction and servo-driven turret system deliver exceptional stability, rigidity, and accuracy, ensuring consistent results even under demanding production conditions.

By combining turning and milling in a single setup, the T6 Series eliminates secondary operations, reduces work-in-process, and increases spindle uptime. The result is a reliable, high-accuracy machining platform that enhances surface finish, part consistency, and overall profitability for manufacturers and their customers.