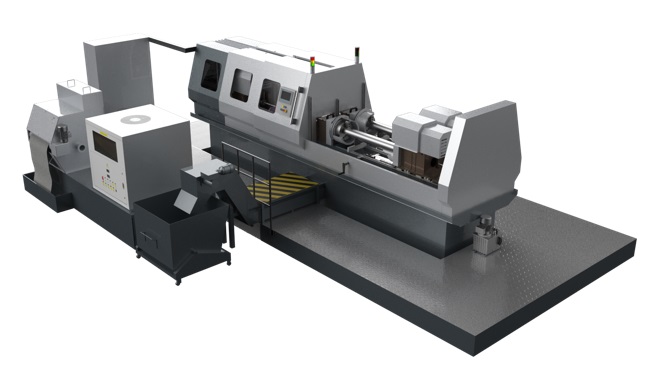

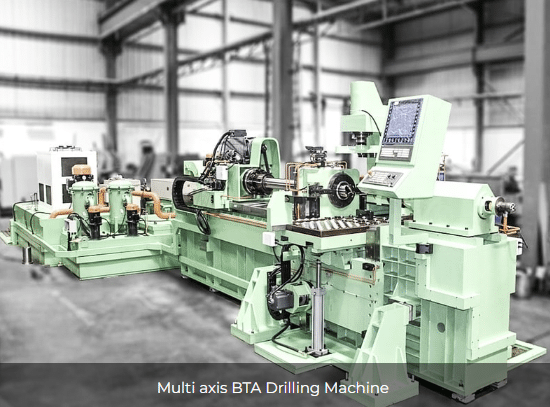

Precihole SPM Series Special Purpose Customized Deep Hole Drilling Machines

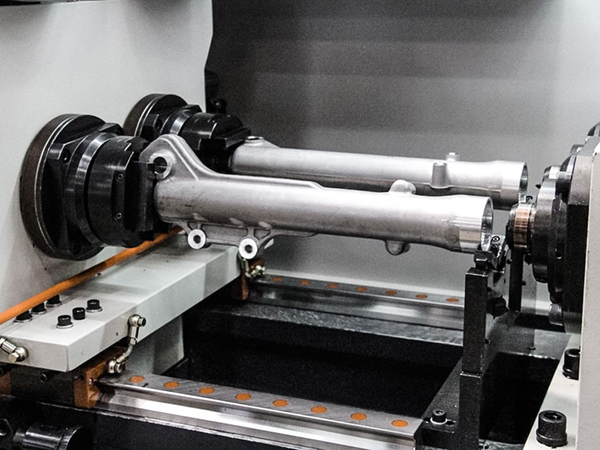

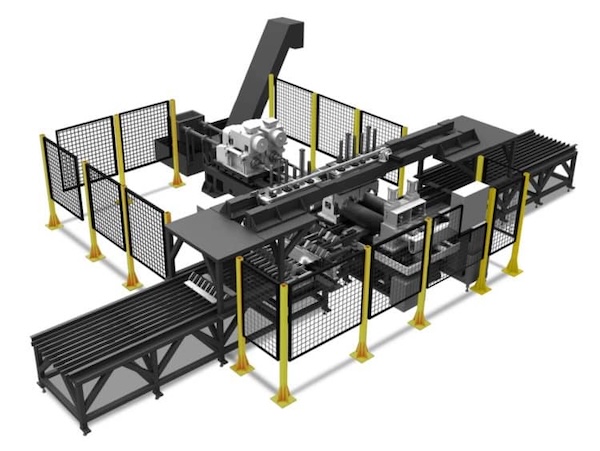

Precihole Machine Tools offers customized deep hole drilling special purpose machines for deep hole drilling and hole finishing applications. Customization in the Precihole SPM Series is what sets us apart from other worldwide machine tool manufacturers. We have experience in manufacturing machines for over 150 special applications in various industries where the requirements did not fit any of our standard machines. We have supplied more than 400 machines that are currently being used by large and medium scale industries around the world. These machines are capable producing high production volumes, feature multi-spindle and multi-axis capabilities, and can be fully or semi-automatic. Tooling and work holding are provided to accommodate your component. Our team of highly experienced engineers works closely with customers to define requirements, study the underlying process, come up with a concept, then design, manufacture and prove out the machine. Every special machine undergoes thorough testing on the floor before dispatch to ensure smooth working in production mode. Professional training, documentation and process engineering are all provided to successfully adapt the machine onsite. The following machines have been “made-to-order” for our customers worldwide:

Machine Features:

Customers Worldwide Include:

Specifications

| Item / Model |

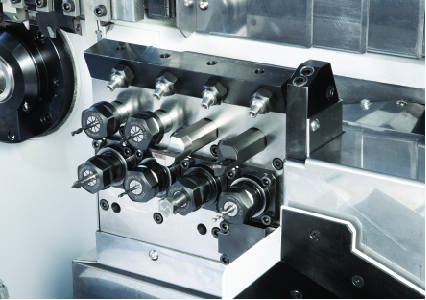

Twin Spindle Automatic BTA Drilling Machines

Request a Quote

|

|---|---|

|

Drilling Diameter Range |

25mm – 80mm |

|

Drilling Depth |

320mm – 950mm |

|

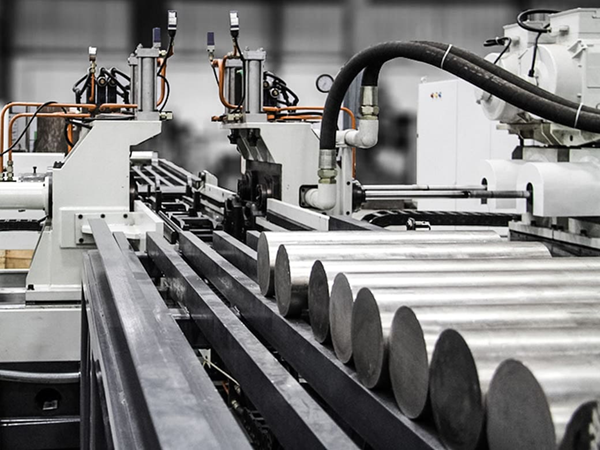

Component |

Billets |

|

Component Material |

Alloy Steel, SS, Duplex |

|

Component Diameter |

180mm – 350mm |

|

Component Loading / Unloading |

Automatic |

|

Number of Spindles |

2 |

|

Chip Collecting System |

Scraper Type Conveyor |

|

Spindle Motor |

39 kW per Spindle |

|

Coolant Tank Capacity |

7,500 Liters |

|

Total Connected Electric Power |

275 kW |

|

Spindle Speed |

150 – 1300 RPM |

|

Feed Rate |

20 – 400 mm/min. |

|

Rapid Traverse Rate |

5000 mm/min. |

|

Machine Footprint |

11200 x 6800 sq. mm |