Horizontal

Machining Centers

CNC Horizontal Machining Centers (HMCs)

Absolute Machine Tools proudly offers four trusted brands of horizontal machining centers — all with decades of experience building CNC machine tools. Our lineup includes a wide range of sizes and capabilities ranging from 5-axis models, palletized and non-palletized models. Whether the application requires high-performance speed, heavy cutting, or large part capacity, there’s no doubt you will find the horizontal machining center you are looking for right here at a competitive price.

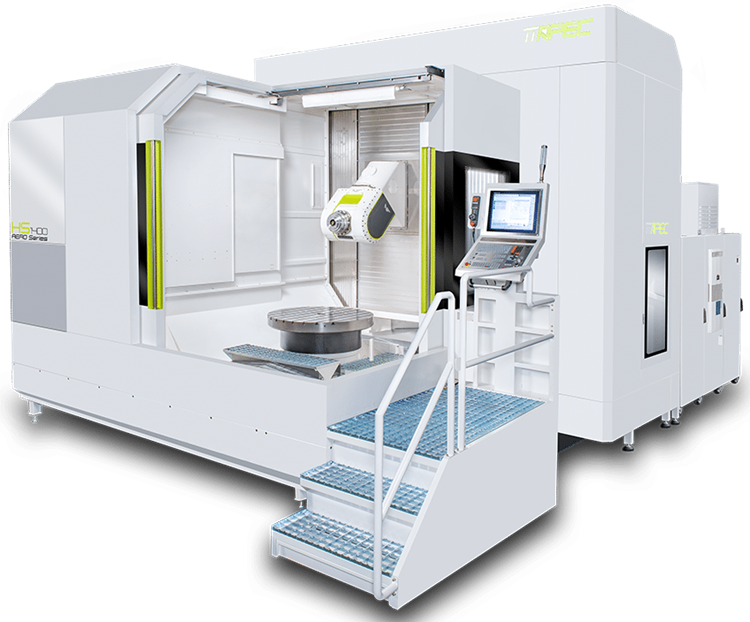

APEC

APEC or Asia Pacific Elite Corporation, is a core subsidiary of TTGroup focused on 5-axis, large gantry-type high speed horizontal machining centers that are especially popular worldwide in industries such as aerospace, automotive, and mold & die. Their HS700 series targets precision machining of aluminum and light alloys with high-speed spindles (up to 20,000 RPM) and multi-pallet capability, ideal for mid-sized aerospace components. In contrast, the HS1400 series is engineered for large, heavy superalloy parts, featuring massive rigidity, torque-heavy spindles (up to 500 Nm), and support for workpieces up to 3.2 tons. Together, these machines reflect APEC’s focus on delivering thermally stable, high-speed, and multi-axis solutions for demanding production environments.

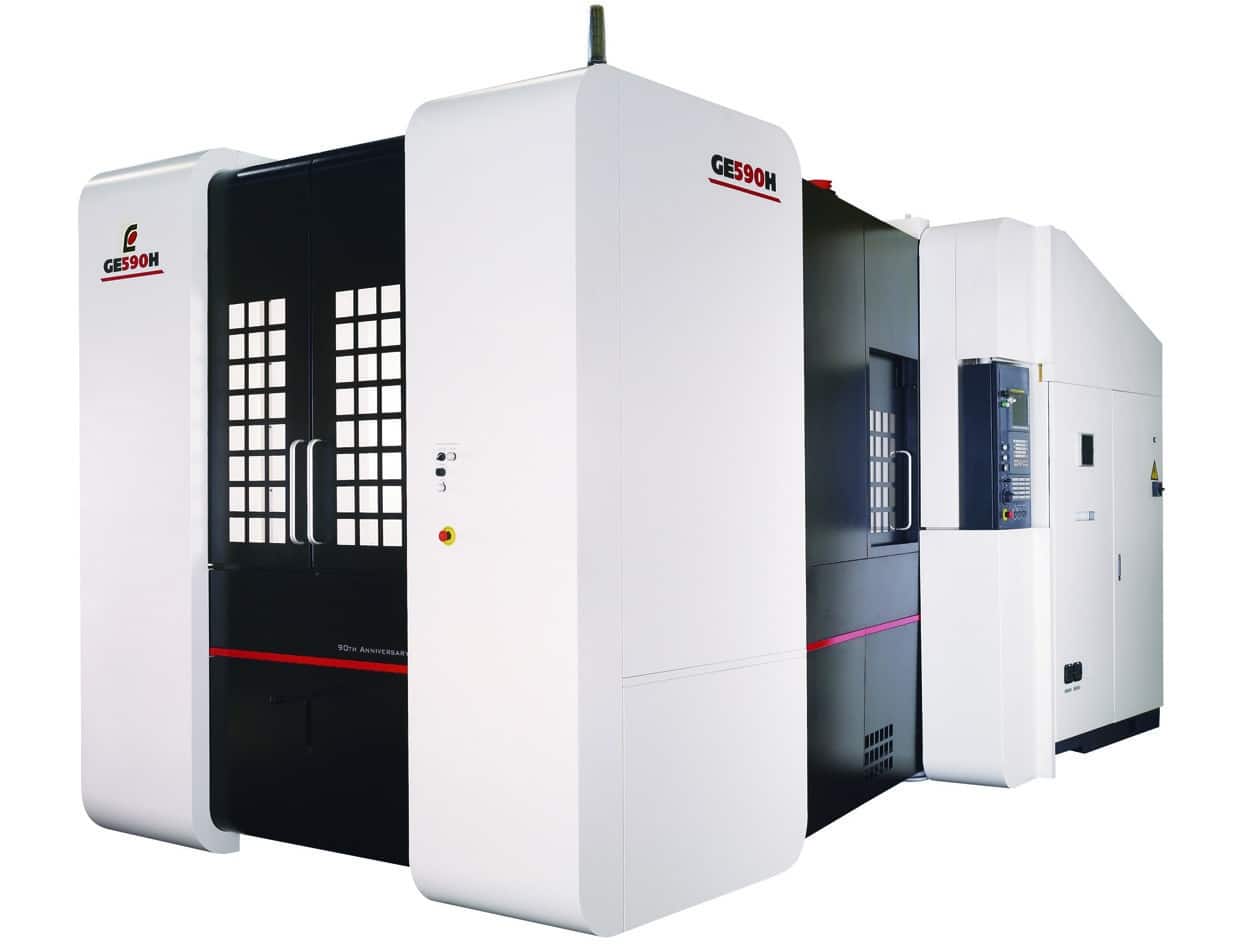

Enshu

Enshu’s GE Series horizontal machining centers include four models designed to deliver high-speed, high-precision performance for modern manufacturing. The GE460H features a 15″ (400 mm) pallet, the GE480H and GE580H are built with 20″ (500 mm) pallets, and the heavy-duty GE590H comes equipped with a 25″ (630 mm) pallet and a powerful 50-taper spindle. Each model is engineered in Japan for maximum uptime, thermal stability, and rapid pallet changes. The GE460H and GE480H offer impressive rapid traverse rates of up to 3,543 IPM — reducing non-cut time by as much as 20%. All four models feature a full 0.001-degree B-axis, fast automatic pallet changers, high-torque spindles up to 60 HP, and thermally controlled components — making the GE Series ideal for applications requiring accuracy, speed, and long-term reliability in demanding production environments.

Johnford

Johnford, a leading Taiwanese manufacturer since 1979, offers robust horizontal machining centers renowned for rigidity, precision, and versatility. Their flagship AHC-1600 features a massive moving-column/table design with a combined 63″ × 32″ flat table (72″, 79″, and 118″ opt.) and 31.5″ B‑axis rotary, supporting up to 10,120 lbs. on the table and 4,400 lbs. on the rotary axis. Built with a 35 HP two-speed 6,000 RPM gearbox spindle, it’s aimed at aerospace and heavy-duty applications (10,000 RPM direct-drive or a 15,000 RPM HSK‑100A opt.). Johnford also builds other horizontal HMCs like the HMC‑500H and HMC‑630H including CAT-50 spindles and multi-pallet capabilities for mid-sized component machining. As with most models of Johnford CNC machine tools, they offer fully customizable horizontal machining centers, tailoring spindle configurations, table sizes, control systems, and automation options to meet virtually any manufacturing requirement from precision aerospace parts to heavy-duty industrial components.

You Ji

You Ji’s HMC Series offers a comprehensive lineup of heavy-duty horizontal machining centers ranging from compact 20″ x 20″ (500 mm × 500 mm) pallets up to massive 133.86″ x 70.87″ (3,400 mm × 1,800 mm) tables, supporting part loads up to 33,069 lbs., and W-axis travel up to 27.5″. Built with a robust box-in-box saddle design, pre-tensioned ball screws, linear guideways, and thermally stable construction, these machines ensure exceptional rigidity and accuracy. Spindle options include 8,000 RPM high-speed configurations and 3,500 RPM two-speed gearboxes for high-torque cutting. Rapid traverse rates range from 93 IPM on smaller models to 46.5 IPM on larger units. Optional features include 5-axis heads, probing systems, and right-angle attachments. Every You Ji HMC can be customized for your specific application — making them an ideal solution for demanding die/mold, aerospace, and heavy-industry machining environments.

Machines

OEMS

APEC 5-Axis Horizontal Machining Centers are specially engineered to conquer the challenges of aerospace SuperAlloy processing. The highly rigidi T-shaped structure design and high-speed ball screw-driven X/Y/Z axes set new standards in precision machining.

Experience the world-class performance of Enshu horizontal machining centers, renowned for their unparalleled accuracy, repeatability, and thermal stability. With features like a 5000 Hours MTBF, swift rapids of 3543”/min in all linear axes, and a high-powered 50HP spindle that accelerates from 0-15000RPM in just 1.9 seconds, Enshu machines are designed to maximize efficiency and reduce non-cutting times. All these features culminate to provide a machining center that not only meets but exceeds high-volume, high-precision machining demands, offering more value at a competitive price.

Johnford AHC series horizontal machining centers have been described as “every job shop’s dream machine.” They’re rigid, reliable, and built to last. The AHC series feature a combination full length flat table for clamping large parts with a flush mounted B axis rotary table in the center, allowing the machine to handle complex 4 axis simultaneous work as well as large parts. With large travels at a great price, these are the machines every shop should have.

You Ji HMCs are the choice for large part machining. Available with or without pallet changers, You Ji offer machines from 800mm to 2500mm pallet size. All models are available with a W-Axis square ram that allows the machine to function as a horizontal boring mill. With many configurations and a variety of options available, You Ji horizontals can be configured to meet virtually any requirement. Find out for yourself why big name publications like Modern Machine Shop and Manufacturing News have written about You Ji Machine Tools exceptional engineering capabilities.

APEC 5-Axis Horizontal Machining Centers are specially engineered to conquer the challenges of aerospace SuperAlloy processing. The highly rigidi T-shaped structure design and high-speed ball screw-driven X/Y/Z axes set new standards in precision machining.

Experience the world-class performance of Enshu horizontal machining centers, renowned for their unparalleled accuracy, repeatability, and thermal stability. With features like a 5000 Hours MTBF, swift rapids of 3543”/min in all linear axes, and a high-powered 50HP spindle that accelerates from 0-15000RPM in just 1.9 seconds, Enshu machines are designed to maximize efficiency and reduce non-cutting times. All these features culminate to provide a machining center that not only meets but exceeds high-volume, high-precision machining demands, offering more value at a competitive price.

Johnford AHC series horizontal machining centers have been described as “every job shop’s dream machine.” They’re rigid, reliable, and built to last. The AHC series feature a combination full length flat table for clamping large parts with a flush mounted B axis rotary table in the center, allowing the machine to handle complex 4 axis simultaneous work as well as large parts. With large travels at a great price, these are the machines every shop should have.

You Ji HMCs are the choice for large part machining. Available with or without pallet changers, You Ji offer machines from 800mm to 2500mm pallet size. All models are available with a W-Axis square ram that allows the machine to function as a horizontal boring mill. With many configurations and a variety of options available, You Ji horizontals can be configured to meet virtually any requirement. Find out for yourself why big name publications like Modern Machine Shop and Manufacturing News have written about You Ji Machine Tools exceptional engineering capabilities.