River CNC EDM Hole Drilling Machines

High-Performance Multi-Axis CNC EDM Drilling for Complex, Safety-Critical Components

The River CNC Series from Ocean Technologies delivers advanced EDM hole drilling capability for industries where precision and repeatability directly impact human safety. Aerospace manufacturers rely on these systems for cooling holes in turbine blades and vanes, fuel injector nozzles, and multi-angle airfoil features that must meet strict aviation standards. Medical and life-science companies depend on the River CNC platform for micro-holes in biopsy needles, catheter tips, stents, pacemakers, and orthopedic implants. In the automotive sector, the series produces precision holes for fuel injection systems, ABS and brake components, and hydraulic and pneumatic assemblies.

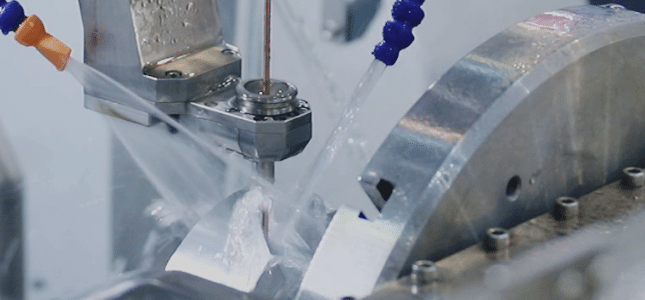

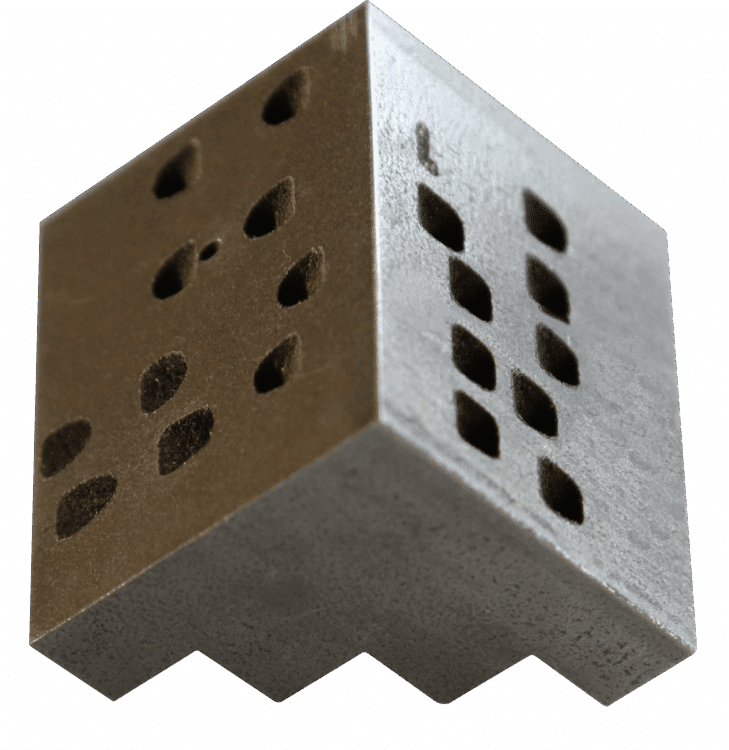

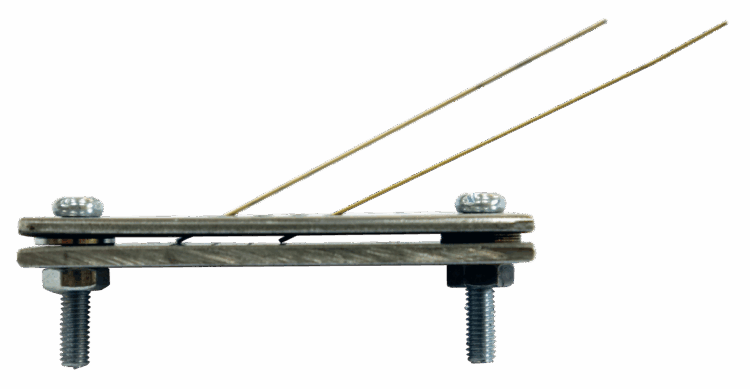

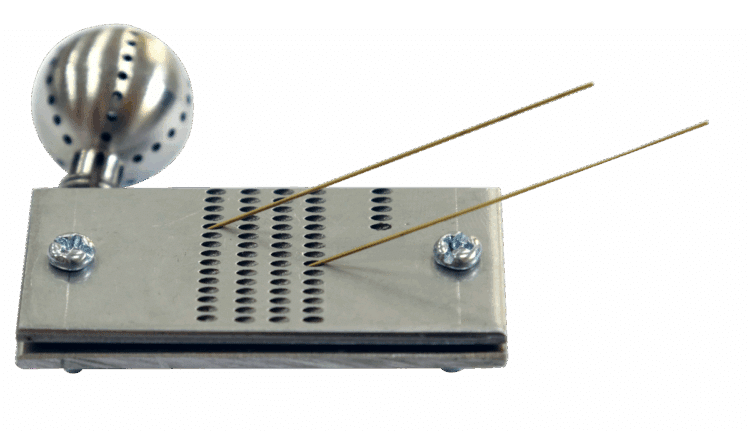

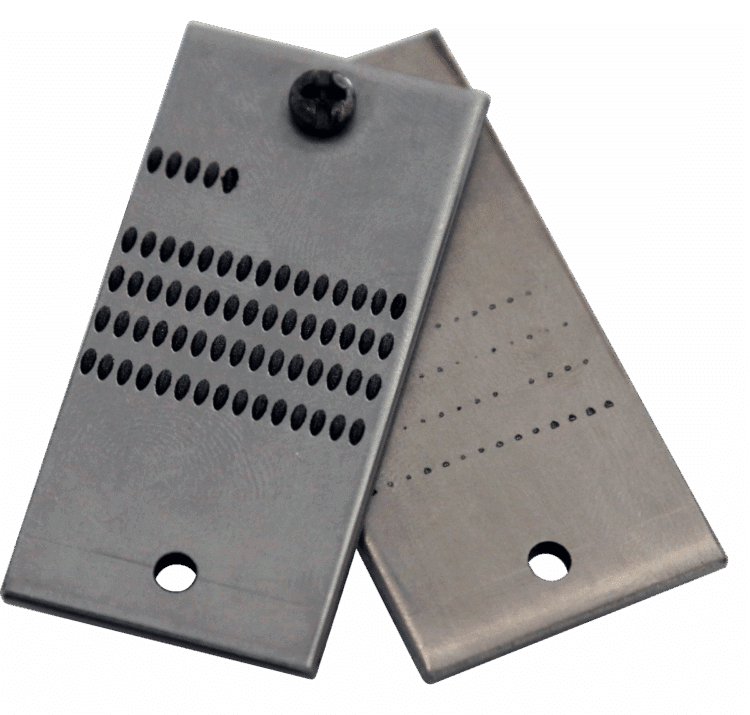

Using controlled high-frequency electrical discharges, the River CNC machines drill accurate holes from 0.1–3.0 mm across a wide range of conductive materials including stainless steel, hardened steel, carbide, titanium, Inconel, superalloys, ceramics, graphite, and more. High-precision servo control, rigid casting construction, and linear guideways ensure stable micro-electrode performance — even when drilling on slopes, curves, or contoured surfaces. These machines can also remove broken taps or drills without damaging the original hole or threads.

Key Features

- Fixed-table design with X/Y/Z mobility for machining large, heavy workpieces

- High-efficiency linear guideways for precise motion control

- 5th-generation control system with intelligent database support

- High-performance machining with minimal electrode wear and excellent surface finish

- Two-year aged Meehanite casting for superior stability and long service life

- Touch-screen controller with user-friendly HMI

- Breakthrough function and AGC 10 blocks for enhanced drilling control

- CAM software for 5-axis and 6-axis drilling

- Available single- and dual-axis rotary tables

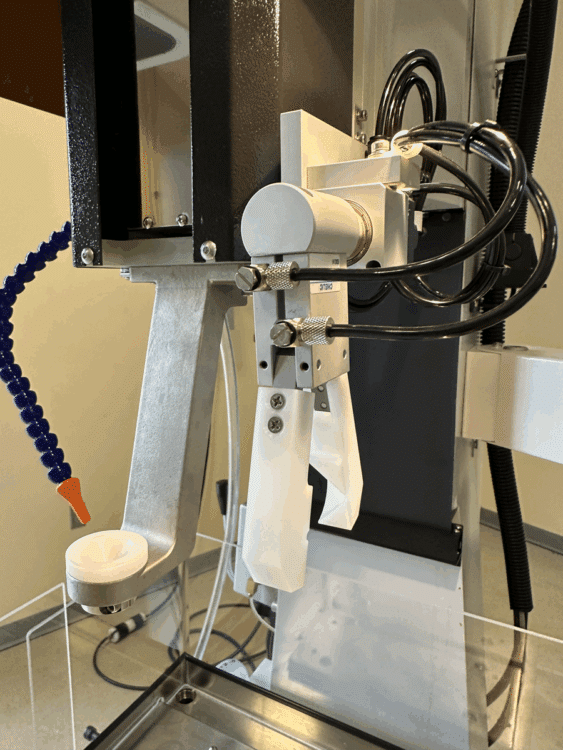

- Extended spindle options (mini spindle)

- 3-, 5-, and 6-axis synchronized drilling capability

- Standard flushing and optional submerged-type water tank

- Tilting head for advanced angular applications

- Gantry-type machine construction on larger models

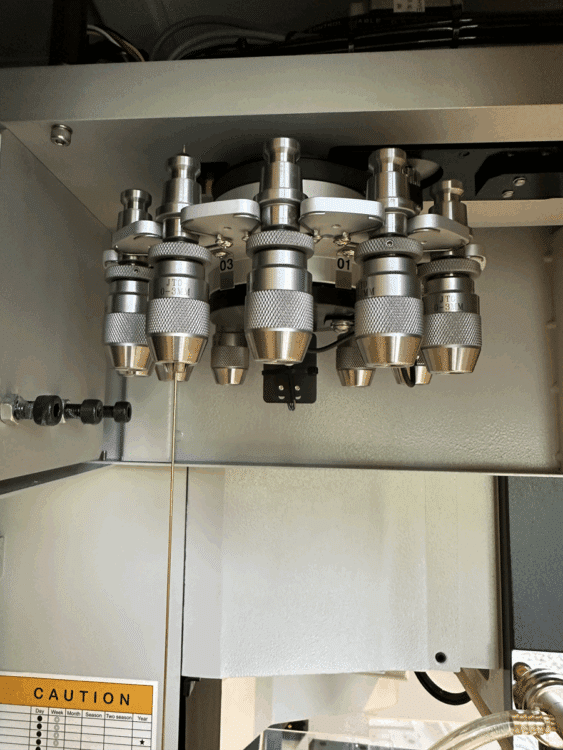

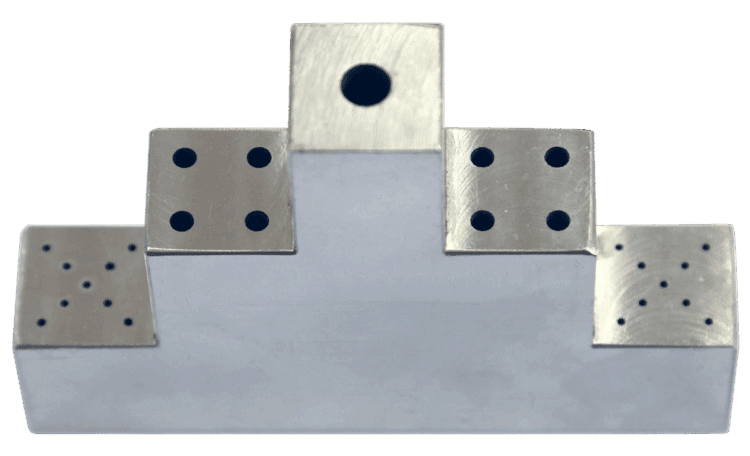

- 12-, 16-, 32-, and 50-station automatic electrode changers

- Optional robotic workpiece changer for lights-out automation

- Milling capabilities for advanced shape generation

- Optimized for irregular and complex geometries

- HP1+ high-speed discharge circuit: 40% faster drilling with 30% less energy usage

Absolute Machine Tools backs every River CNC model with dedicated EDM applications engineering and a highly trained service team. Contact us today to request a test cut, schedule a demo, or discuss your CNC drilling requirements with an EDM specialist.

Specifications

| Item / Model |

River 300

Request a Quote

|

River 350

Request a Quote

|

River 600

Request a Quote

|

River 800

Request a Quote

|

River 1000

Request a Quote

|

|---|---|---|---|---|---|

|

X Axis Travel |

11.8″ |

13.8″ |

23.6″ |

31.5″ |

39.4″ |

|

Y Axis Travel |

7.9″ |

9.8″ |

15.7″ |

23.6″ |

47.2″ |

|

Z Axis Travel |

7.9″ |

11.8″ |

15.7″ |

19.7″ |

39.4″ |

|

W Axis Travel |

13.8″ |

17.7″ |

17.7″ |

19.7″ |

27.6″ |

|

Work Table Size |

13.8″ x 9.9″ |

23.6″ x 11.8″ |

23.6″ x 15.7″ |

31.5″ x 23.6″ |

47.2″ x 49.2″ |

|

Max. Workpiece Height |

7.1″ |

13″ |

15.7″ |

19.7″ |

43.3″ |

|

Max. Workpiece Weight |

330 lbs. |

550 lbs. |

1,764 lbs. |

3,978 lbs. |

6,614 lbs. |

|

Max. Current |

25 Amps |

25 Amps |

25 Amps (32 / 64 opt.) |

32 Amps (64 opt.) |

32 Amps (64 opt.) |

|

Power Capacity |

3.8 KVA |

3.8 KVA |

3.8 KVA |

3.8 KVA |

6 KVA |

|

Electrode Diameter |

0.004″ – 0.118″ |

0.004″ – 0.118″ |

0.004″ – 0.118″ |

0.004″ – 0.118″ |

0.004″ – 0.118″ |

|

Machine Dimensions |

43.3″ x 39.4″ x 78.7″ |

43.3″ x 39.4″ x 78.7″ |

40.6″ x 64.2″ x 77.2″ |

88.6″ x 96.5″ x 99.2″ |

171.3″ x 167.3″ x 157.5″ |

|

Machine Weight |

1,323 lbs. |

1,764 lbs. |

2,425 lbs. |

5,500 lbs. |

7,716 lbs. |