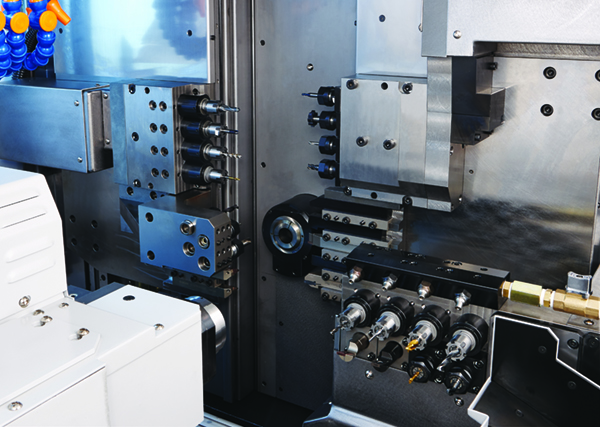

Nexturn SA(XIII) Series – 11-Axis, 3 Channels & 3 Y-Axes Swiss Lathes

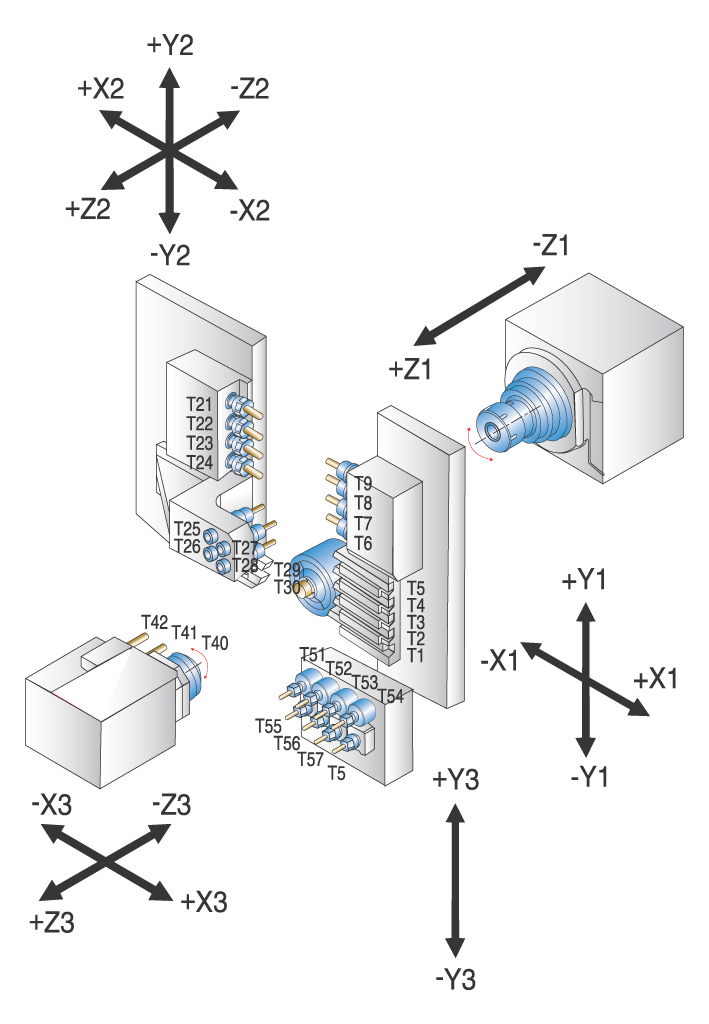

The Nexturn SA(XIII) Series includes two high-performance models — the SA-32XIII (1.26” / 32 mm) and SA-38XIII (1.50” / 38 mm) — each engineered with 11 axes, a 3-channel dual opposed gang tool post, and three independent Y-axes for advanced multi-tool synchronization.

These precision CNC automatic lathes feature a 33-tool capacity, exchangeable rotary guide bushings, and modular rotary spindles, providing unmatched flexibility for both long and short-part machining. Built for manufacturers in medical, aerospace & defense, automotive, electronics, and general precision part production, the SA(XIII) Series delivers ultra-accurate, high-speed performance that competes head-to-head with leading brands such as Marubeni Citizen-Cincom, Star, Tornos, Hanwha, Swiss-Tech, Swissturn, Mazak, and Doosan.

Key Features

- 11-axis configuration (Z1, X1, Y1, Z2, X2, Y2, Z3, X3, Y3, C1, C2) with 3-channel simultaneous control

- Three independent Y-axes for advanced multi-plane machining and simultaneous tool operation

- 33 total tool capacity, including up to 14 live tools with ER-16 collets for superior rigidity

- Main spindle: 10 HP / 8000 RPM built-in motor with 0.001° C-axis positioning and pneumatic brake

- Sub spindle: 3 HP / 8000 RPM belt-driven motor, fully synchronized for front/back machining

- Full-stroke rotary synchronous guide bushing, spline-shaft driven with dual-bearing support for long-part precision

- Optional non-guide bushing configuration for short parts, reduced remnants, and cold-drawn materials

- High-speed traverse: 1260 IPM rapid rate; .039–236 IPM cutting feed

- Machine base: one-piece cast-iron frame designed with FEM analysis for maximum rigidity and stability

- Control: FANUC 31i-T B Plus triple-path CNC with Ethernet, USB, and optional Manual Guide i conversational interface

- Live tooling: 1.3 HP, 6000 RPM spindles for cross, face, and back-end milling, drilling, and tapping operations

- Standard equipment: part conveyor, pneumatic spindle brakes, part-ejection detection, centralized lube, coolant flow detection, and 3-color tower light

- Automation ready: compatible with A+ Automation OB7, Fanuc CRX, and Mitsubishi LoadMate Plus™ robotic tending systems for lights-out production

Specifications

| Item / Model |

SA-32XIII

Request a Quote

|

SA-38XIII

Request a Quote

|

SA-45XIII

Request a Quote

|

|---|---|---|---|

|

FREE TRACER 32V Bar Feeder |

FREE TRACER 51V Bar Feeder |

FREE TRACER 32V Bar Feeder Package | |

|

Number of Axes |

11 |

11 |

11 |

|

Number of Channels |

3 |

3 |

3 |

|

Bar Capacity (Front/Rear) |

32 mm / 32 mm |

38 mm / 38 mm |

45 mm / 45 mm |

|

Guide Bushing Type |

Synchronous |

Synchronous |

Synchronous |

|

Main Spindle |

10 HP / 8,000 RPM |

10 HP / 8,000 RPM |

20 HP / 6,000 RPM |

|

Sub Spindle |

3 HP / 8,000 RPM |

3 HP / 8,000 RPM |

7.5 HP / 6,000 RPM |

|

Max. Turn Length |

11″ |

11″ |

4.72″ |

|

Total Tools |

29 |

29 |

24 |

|

Fixed Tools (Front/Rear) |

13 / 4 |

13 / 4 |

13 / 4 |

|

Live Tools (Front/Rear) |

8 / 4 |

8 / 4 |

7 / 4 |

|

Live Tools |

6,000 RPM |

6,000 RPM |

6,000 RPM |

|

Live Tools |

1.3 HP1.3 HP / 6,000 RPM |

1.3 HP / 6,000 RPM |

1.3 HP / 6,000 RPM |

|

C Axis Contouring |

Main/Sub |

Main/Sub |

Main/Sub |

|

CNC Control |

FANUC 31iT |

FANUC 31iT |

FANUC 31iT |

|

Weight |

8,140 lbs. |

8,140 lbs. |

8,800 lbs. |

Benefits for Metal Cutting Manufacturers

The SA(XIII) Series is purpose-built for manufacturers who demand maximum productivity, precision, and process flexibility. Its 3-channel control and triple Y-axis configuration enable up to three tools to cut simultaneously on different planes — dramatically reducing non-cut time while optimizing tool utilization and cycle efficiency. The machine’s one-piece FEM-analyzed cast-iron base ensures outstanding rigidity, vibration damping, and long-term accuracy under heavy cutting conditions.

With built-in motor spindles on both main and sub stations reaching 8000 RPM, and full C-axis control at 0.001° positioning, the SA(XIII) performs complex milling and turning operations in a single setup. Pre-tensioned ballscrews, THK linear guideways, and servo learning oscillation contribute to superior motion control, chip management, and surface integrity. Together, these technologies provide high-precision, high-speed machining performance, achieving cycle time reductions up to 30% compared to conventional Swiss-type lathes.

Ideal Cutting Applications

- Precision medical components (bone screws, cannulas, orthopedic pins)

- Aerospace fasteners, sensor housings, and hydraulic fittings

- Automotive connectors, shafts, and precision valve components

- Miniature electronic parts requiring multi-axis milling and fine turning

- High-volume small-part production where simultaneous front/back machining boosts throughput