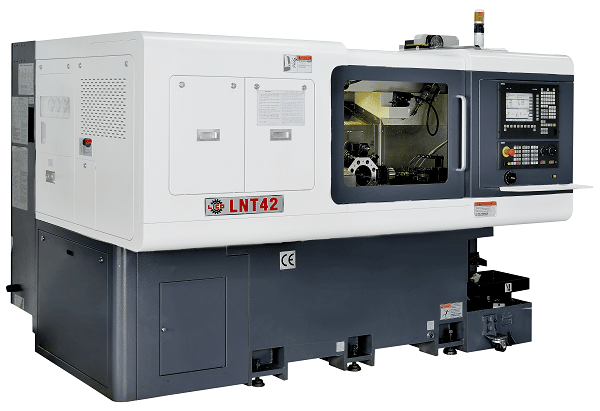

LICO LNTS Series Multi-Slide CNC Screw Machines

High-Speed, Multi-Tool CNC Turning for Short-Cycle Production

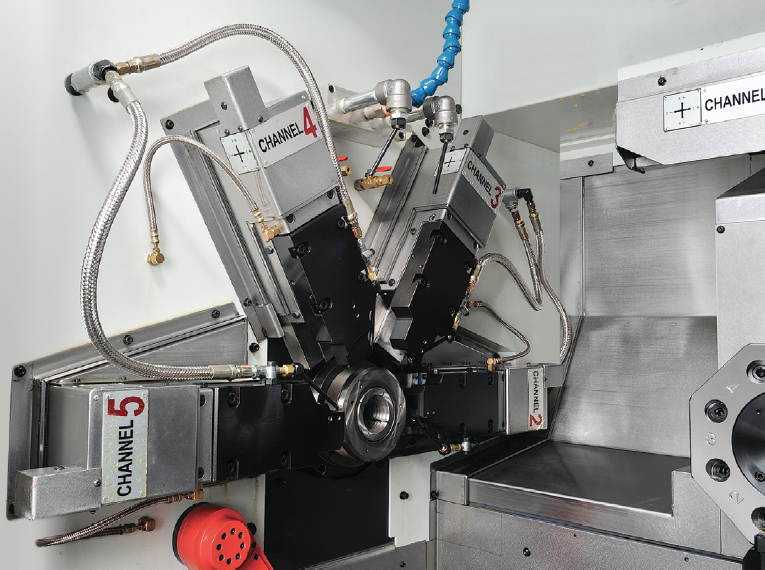

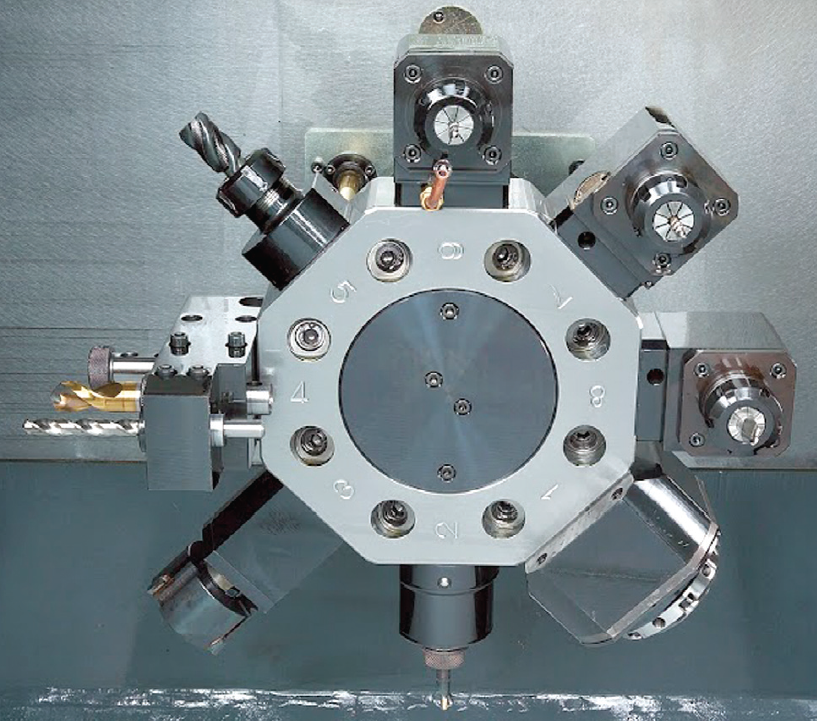

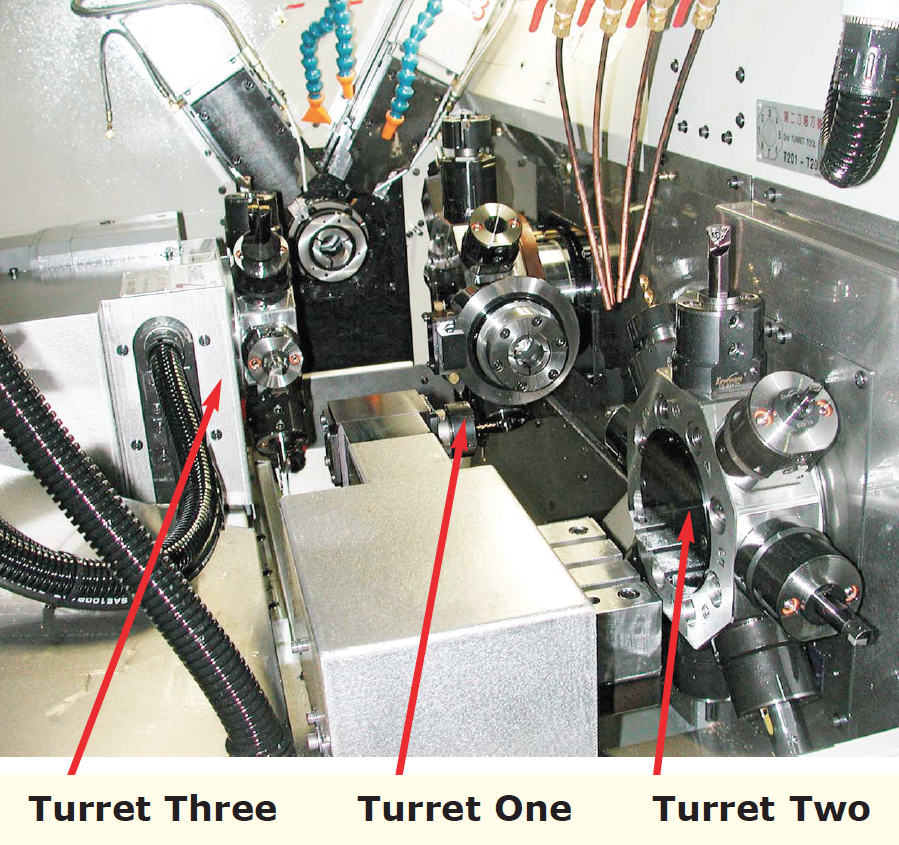

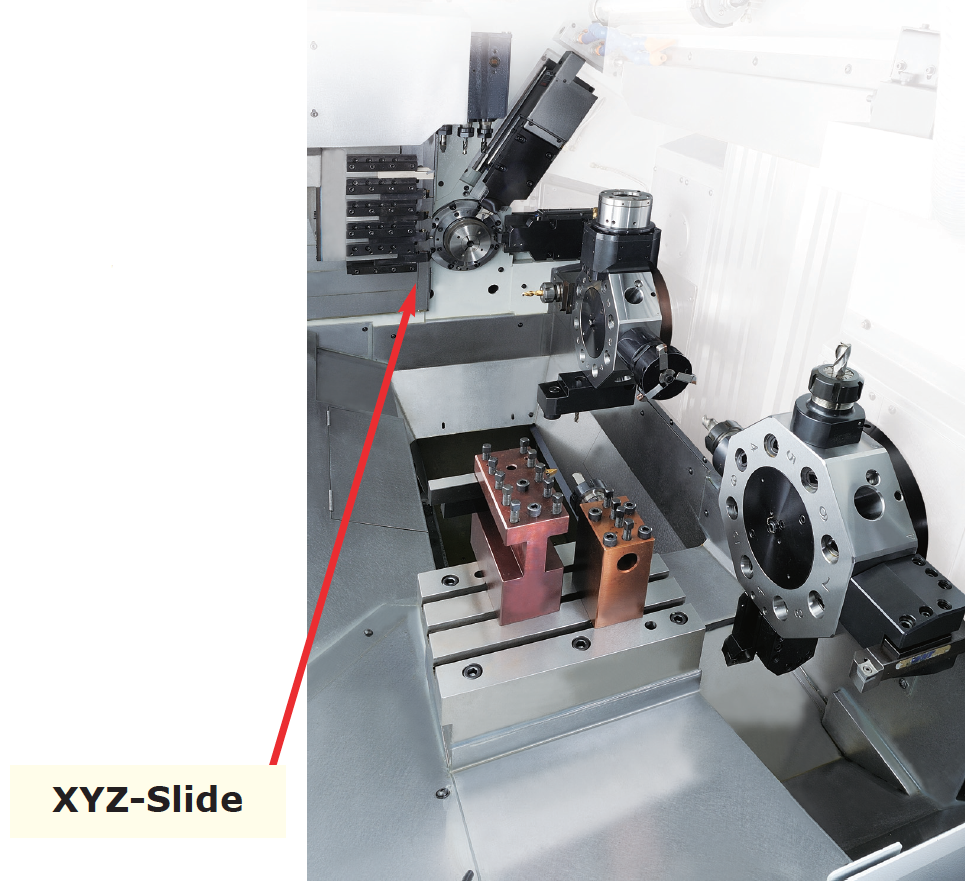

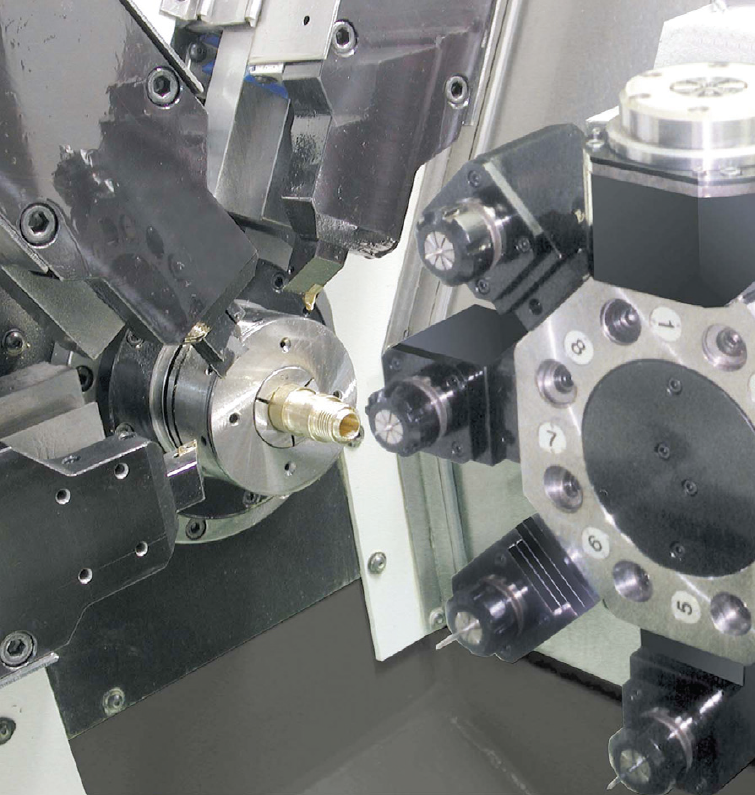

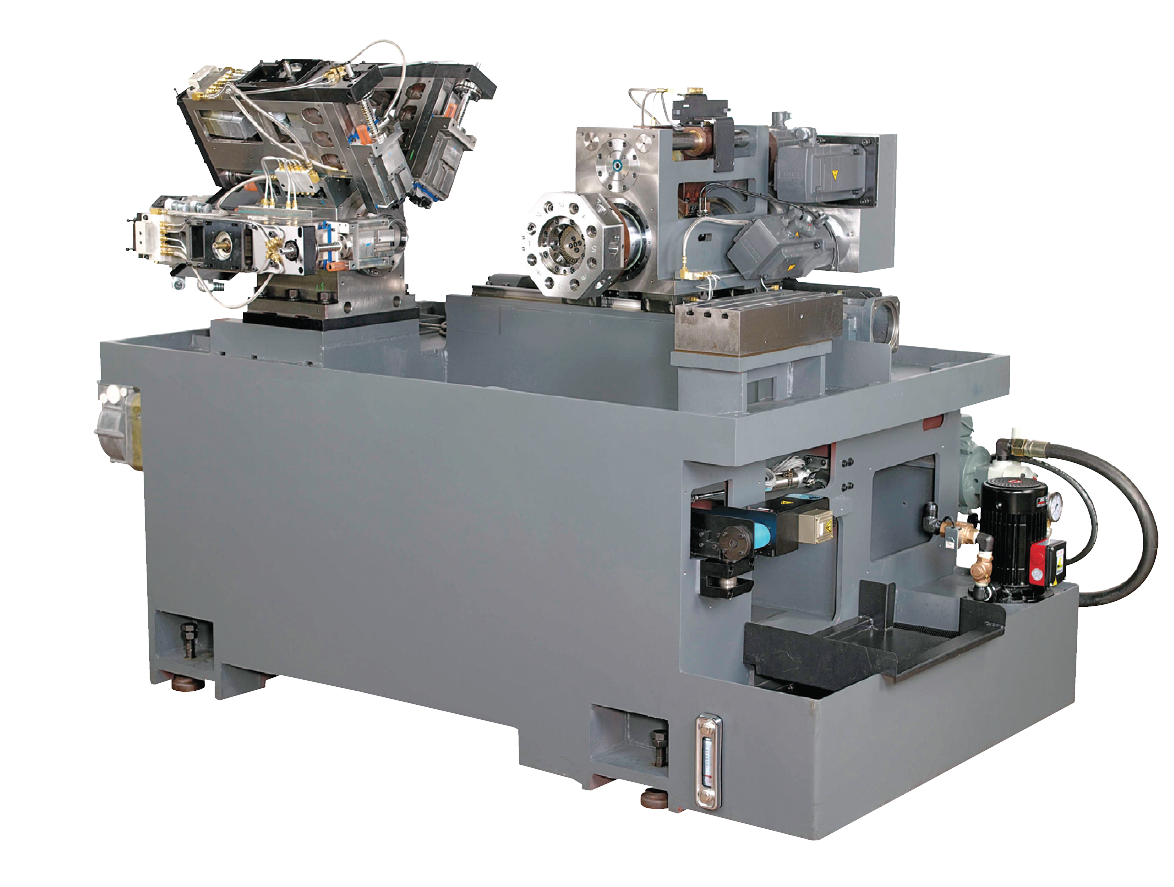

The LICO LNTS Series is a high-performance multi-slide CNC screw machine engineered for ultra-fast, continuous production of medium-to-complex turned components. Built to rival the throughput of traditional cam-driven machines—while offering the flexibility, control, and accuracy of CNC—the LNTS delivers exceptional efficiency for demanding, high-volume environments. Its unique architecture allows up to five tools to cut simultaneously, dramatically shortening cycle times without sacrificing precision.

Key Features

Absolute Machine Tools can help you evaluate whether the LNTS is the right fit for your production environment. Contact us today for a quote or technical review and see how LICO’s most popular multi-slide CNC turning center can transform your throughput.

Specifications

| Item / Model |

LNT36S

Request a Quote

|

LNT42S

Request a Quote

|

LNT51S

Request a Quote

|

LNT65S

Request a Quote

|

|---|---|---|---|---|

|

Capacities | ||||

|

Bar Capacity ∅ Thru Bore |

36 mm (1.42″) |

42 mm (1.65″) |

51 mm (2.00″) |

65 mm (2.56″) |

|

Max Turning Length |

130 mm (5.12″) |

130 mm (5.12″) |

130 mm (5.12″) |

130 mm (5.12″) |

|

Spindle | ||||

|

Spindle Center Height (approx.) |

1,000 mm (40″) |

1,000 mm (40″) |

1,000 mm (40″) |

1,000 mm (40″) |

|

Collet Chuck Type |

F42 (36 mm) |

B42 (42 mm) |

Hainbuch 52 |

B65 (65 mm) |

|

Motor Power (Continuous) |

15 kW (20 HP) |

15 kW (20 HP) |

15 kW (20 HP) |

15 kW (20 HP) |

|

Max. Spindle Speed |

6,000 RPM |

5,000 RPM |

4,500 RPM |

4,000 RPM |

|

Cross Slide | ||||

|

X-Axis Travel (standard) |

70 mm (2.76″) |

70 mm (2.76″) |

70 mm (2.76″) |

70 mm (2.76″) |

|

X-Axis Travel (ext. opt.) |

110 mm (4.33″) |

110 mm (4.33″) |

110 mm (4.33″) |

110 mm (4.33″) |

|

Z-Axis Travel |

115 mm (4.53″) |

115 mm (4.53″) |

115 mm (4.53″) |

115 mm (4.53″) |

|

Rapid Traverse |

22,000 |

22,000 |

26,400 |

26,400 |

|

Max. Feed Rate |

5 meters/min. (197″/min.) |

5 meters/min. (197″/min.) |

5 meters/min. (197″/min.) |

5 meters/min. (197″/min.) |

|

Resolution |

0.001 mm (0.0001″) |

0.001 mm (0.0001″) |

0.001 mm (0.0001″) |

0.001 mm (0.0001″) |

|

Turret Slide | ||||

|

Tool Positions |

8 |

8 |

8 |

8 |

|

Tool Shank Type |

VDI-30 x 55 |

VDI-30 x 55 |

VDI-30 x 55 |

VDI-30 x 55 |

|

X-Axis Travel |

160 mm (6.3″) |

160 mm (6.3″) |

160 mm (6.3″) |

160 mm (6.3″) |

|

Z-Axis Travel |

500 mm (19.7″) |

500 mm (19.7″) |

500 mm (19.7″) |

500 mm (19.7″) |

|

Turning Tool Section |

20 mm sq. (3.4″ sq.) |

20 mm sq. (3.4″ sq.) |

20 mm sq. (3.4″ sq.) |

20 mm sq. (3.4″ sq.) |

|

Indexing Time |

0.28 sec. / 180° – 0.6 sec. |

0.28 sec. / 180° – 0.6 sec. |

0.28 sec. / 180° – 0.6 sec. |

0.28 sec. / 180° – 0.6 sec. |

|

Subspindle (standard) | ||||

|

Collet Chuck Type |

TNS42 |

TNS42 |

TNS42 |

TNS42 |

|

Power |

5 HP |

5 HP |

5 HP |

5 HP |

|

Max. Speed |

3,000 RPM |

3,000 RPM |

3,000 RPM |

3,000 RPM |

|

Machine | ||||

|

Dimensions (LxWxH) |

2804 x 1848 x 1935 mm (110″ x 72″ x 76″) |

2804 x 1848 x 1935 mm (110″ x 72″ x 76″) |

2804 x 1848 x 1935 mm (110″ x 72″ x 76″) |

2804 x 1848 x 1935 mm (110″ x 72″ x 76″) |

|

Weight |

3,200 kg (7,040 lbs) |

3,200 kg (7,040 lbs) |

3,200 kg (7,040 lbs) |

3,200 kg (7,040 lbs) |

|

Hydraulic Tank Capacity |

30 L (8 gallons) |

30 L (8 gallons) |

30 L (8 gallons) |

30 L (8 gallons) |

|

Hydraulic Pump Motor |

1 kW (1.3 HP) |

1 kW (1.3 HP) |

1 kW (1.3 HP) |

1 kW (1.3 HP) |

|

Coolant Tank Capacity |

200 L (53 gallons) |

200 L (53 gallons) |

200 L (53 gallons) |

200 L (53 gallons) |

|

Flood Coolant Motor |

0.75 kW (1 HP) |

0.75 kW (1 HP) |

0.75 kW (1 HP) |

0.75 kW (1 HP) |

|

High Pressure Coolant Motor |

2.2 kW (3 HP) |

2.2 kW (3 HP) |

2.2 kW (3 HP) |

2.2 kW (3 HP) |

|

High Pressure Coolant Flow |

18 L/min. @ 70 kg/cm2 (5 gal/min. @ 1,000 PSI) |

18 L/min. @ 70 kg/cm2 (5 gal/min. @ 1,000 PSI) |

18 L/min. @ 70 kg/cm2 (5 gal/min. @ 1,000 PSI) |

18 L/min. @ 70 kg/cm2 (5 gal/min. @ 1,000 PSI) |

|

Lubrication Capacity |

2 L / 10 sec. (10 cc / 10 sec.) |

2 L / 10 sec. (10 cc / 10 sec.) |

2 L / 10 sec. (10 cc / 10 sec.) |

2 L / 10 sec. (10 cc / 10 sec.) |

|

Total Power Used* |

25 kVA |

25 kVA |

30 kVA |

30 kVA |

Benefits for Metal Cutting Manufacturers

Ideal Cutting Applications

In Stock and Ready for Immediate Delivery

Power specifications can change without prior notice. Mitsubishi CNC Controls are standard, FANUC and Siemens CNC Controls are optional.