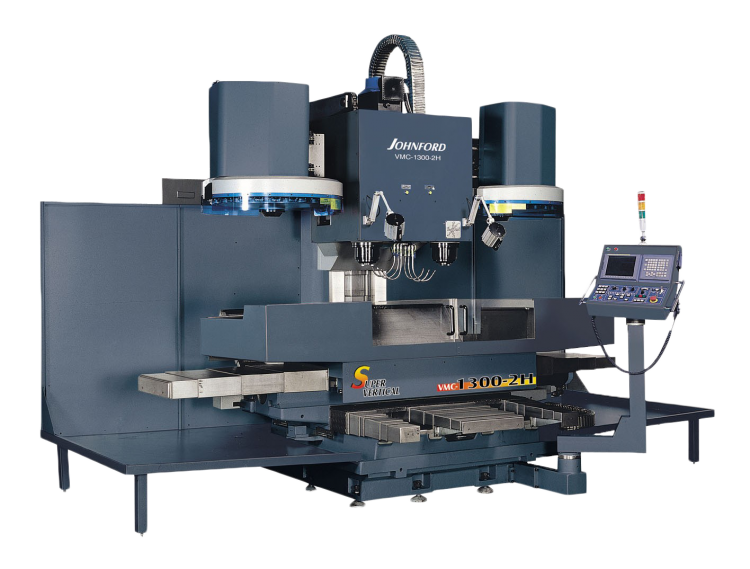

Johnford SV and VMC Twin Spindle Series

The three-machine series of Johnford SV and VMC twin spindle vertical machining centers are box-way, geared-head, C-frame machines that feature solid heavily-ribbed Meehanite cast iron construction to eliminate vibration and ensure excellent surface finishes and long cutting tool life. The machines offer X-Y-Z travel of 45″ x 21″ x 25″ (1125 mm x 525 mm x 626 mm) to 51″x 34″ x 28″ (1275 mm x 850 mm x 700 mm). Table sizes range from 48″ x 20″ (1220 mm x 500 mm) to 59″ x 28″ (1500 mm x 710 mm)

Two machines in the series have 20 hp spindles fitted with 40 taper toolholding systems, while largest machine has a 35 hp, 50 taper spindle. Distance between the spindles is 17″ (425 mm) on the smallest machine and 25″ (635 mm) on the others. Every machine has a 24-tool capacity automatic tool changer, with 32, 40, 60, 80 and 120 tools optional.

Other options include 4th and 5th axis rotary tables, automatic pallet changer, through-coolant spindle, and high speed machining capabilities.

Specifications

| Item / Model |

SV-45-2H

Request a Quote |

VMC-1300-2H

Request a Quote |

VMC-1300HD-2H

Request a Quote |

|---|---|---|---|

|

X Axis Travel |

45″ |

51″ |

51″ |

|

Y Axis Travel |

21″ |

34″ |

34″ |

|

Z Axis Travel |

25″ |

28″ |

28″ |

|

Table Size |

48″ x 20″ |

59″ x 28″ |

59″ x 28″ |

|

Table Load Capacity |

3,300 lbs. |

7,100 lbs. |

7,100 lbs. |

|

Spindle HP |

20 HP |

20 HP |

35 HP |

|

Spindle Taper |

40 |

40 |

50 |

|

Spindle RPM |

10,000 RPM |

10,000 RPM |

6,000 RPM (8,000 / 10,000 RPM opt.) |

|

Spindle Drive |

2 Speed Gearbox |

2 Speed Gearbox |

2 Speed Gearbox |

|

ATC Capacity (Arm-Type) |

24 |

24 |

24 |

|

Distance of Spindles |

17″ |

25″ |

25″ |

|

Machine Weight |

17,800 lbs. |

30,800 lbs. |

32,500 lbs. |