Johnford SDMC Series – CNC Bridge Mills

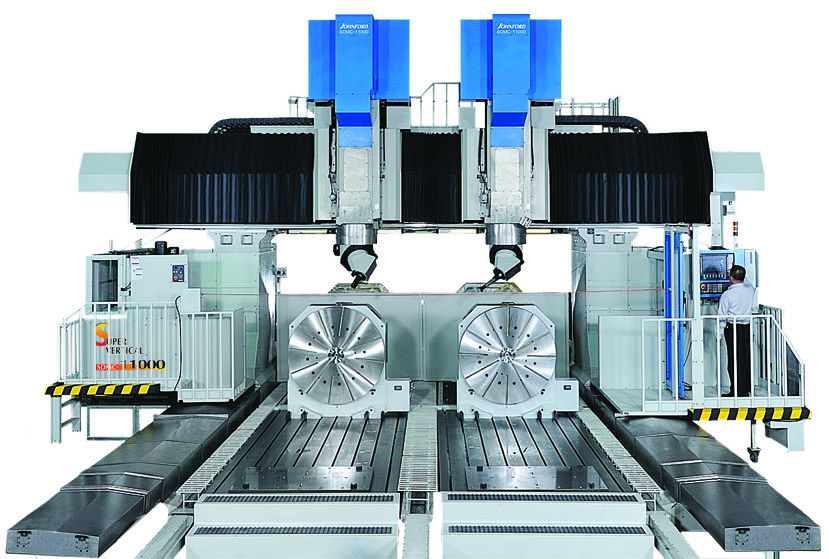

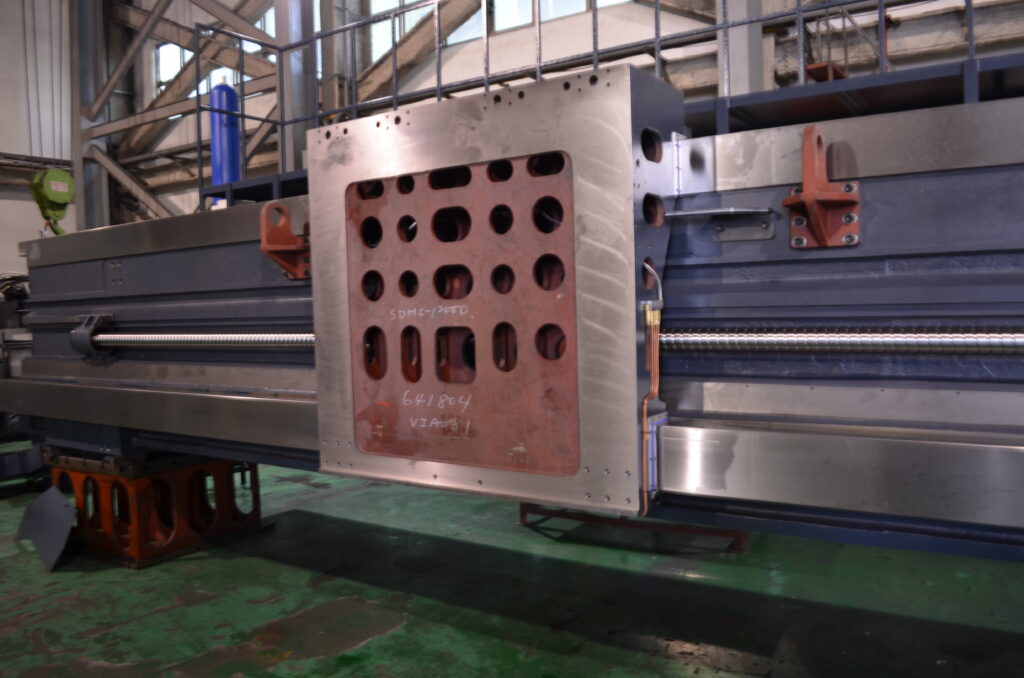

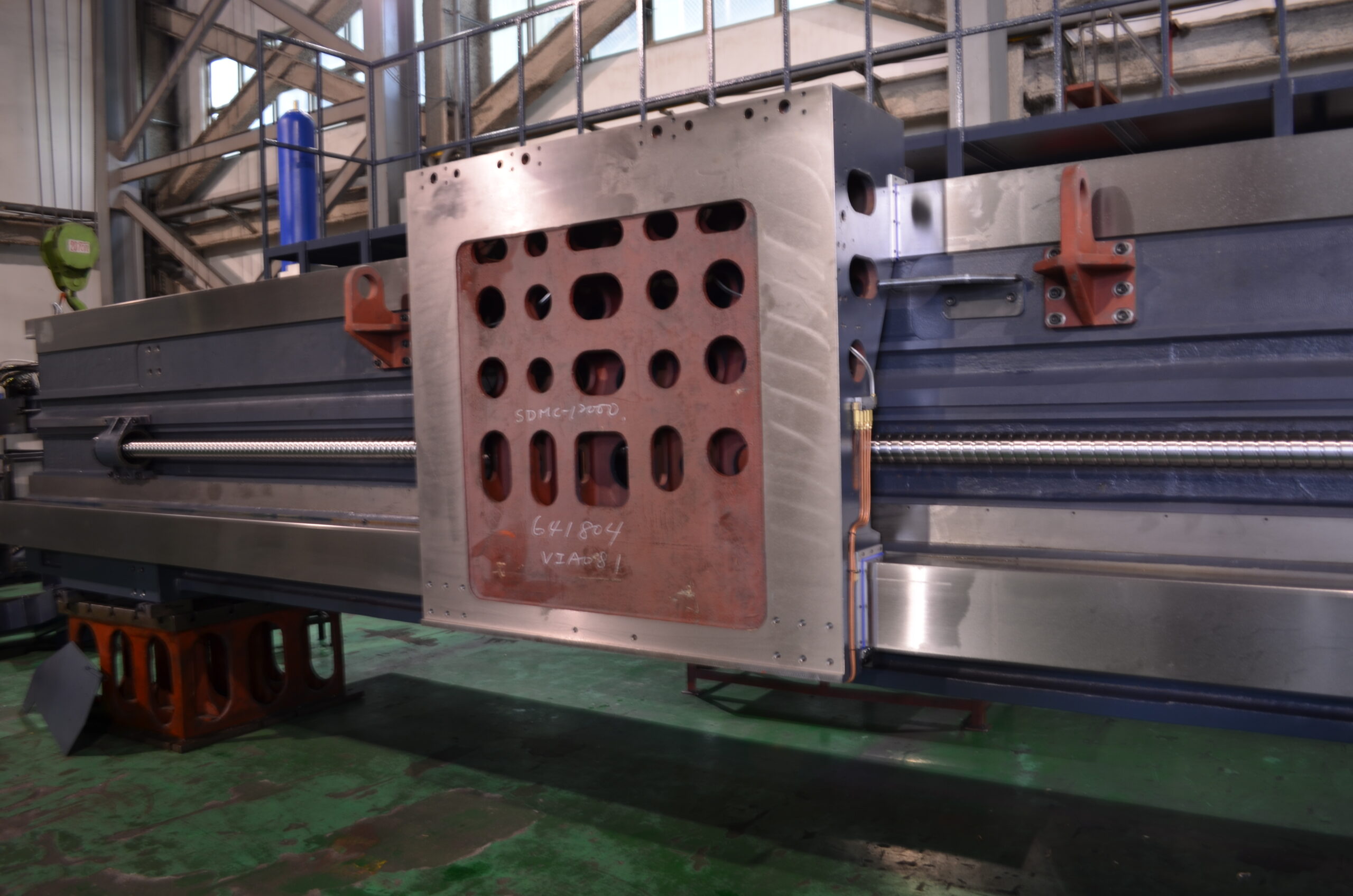

The Johnford SDMC Series delivers exceptional flexibility and structural integrity for machining the largest and heaviest workpieces. These sliding column, fixed-table bridge mills feature machine weights exceeding 400,000 lbs and travels up to 30 meters, providing unlimited table load capacity and absolute accuracy across long production runs. Models are available with X-axis travels up to 25,000 mm (984″), and can be configured as 3-Axis, 5-Face, or full 5-Axis machines to match part geometries and complexity requirements. Custom machine configurations are also available to meet specific manufacturing needs.

Benefits for Metal Cutting Manufacturers

Johnford SDMC CNC bridge mills help manufacturers meet demanding part tolerances and production schedules—especially on components too large or heavy to reposition during machining. The fixed-table, sliding column design supports virtually unlimited table weights, reducing setup complexity while enhancing rigidity, stability, and accuracy across extended travels. This leads to consistent ultra-fine surface finishes, shorter cycle times, and increased process reliability for critical industries.

Whether machining aerospace bulkheads, turbine casings, or mold bases, SDMC bridge mills deliver the stability and horsepower required for deep cavity milling, multi-plane accuracy, and repeatable performance. The result: improved throughput, fewer setups, and long-term machine stability—even under heavy cutting conditions. For high-mix, large-format parts, the SDMC Series is a cost-effective solution engineered for both flexibility and longevity.

Key Features

Ideal Cutting Applications

Custom-Engineered to Fit Your Needs

Every Johnford SDMC bridge mill is available with custom-built travels, head configurations, and structural modifications to meet your exact manufacturing requirements. Whether you need expanded Y-axis clearance, extended Z/W travels, specialized toolchanger capacity, or integration with automation systems, Johnford’s engineering team can tailor the machine to your production environment. This flexibility ensures the SDMC platform delivers optimal performance no matter how demanding the part or application.

📞 Ready to Build Bigger?

No matter which SDMC configuration you choose — 3-axis, 5-face, or full 5-axis — each machine is engineered with Johnford’s signature strength, accuracy, and flexibility.

Contact us today to spec out your custom machine or request a quote.

Looking for a different size/capability? Check out other models in the DMC Series:

Specifications

| Item / Model |

SDMC-5000

Request a Quote |

SDMC-6000

Request a Quote |

SDMC-7000

Request a Quote |

SDMC-8000

Request a Quote |

SDMC-9000

Request a Quote |

SDMC-10000 – 25000

Request a Quote |

|---|---|---|---|---|---|---|

|

X Travel |

197″ |

236″ |

275″ |

315″ |

354″ |

394″ – 984″ |

|

Y Travel |

72″ – 197″ |

72″ – 236″ |

72″ – 236″ |

72″ – 236″ |

72″ – 236″ |

72″ – 236″ |

|

Z Travel |

42″ (48″/60″ opt.) |

42″ (48″/60″ opt.) |

42″ (48″/60″ opt.) |

42″ (48″/60″ opt.) |

42″ (48″/60″ opt.) |

42″ (48″/60″ opt.) |

|

Distance Between Columns |

71″ – 197″ |

71″ – 236″ |

71″ – 236″ |

71″ – 236″ |

71″ – 236″ |

71″ – 236″ |

|

W Axis (opt.) |

39.4″ – 78.7″ |

39.4″ – 78.7″ |

39.4″ – 78.7″ |

39.4″ – 78.7″ |

39.4″ – 78.7″ |

39.8″ – 78.7″ |

|

Table Size |

197″ x 52″ – 157″ |

236″ x 52″ – 157″ |

275″ x 52″ – 216″ |

315″ x 52″ – 216″ |

354″ x 52″ – 216″ |

394″ – 984″ x |

|

Table Load |

11,000 lbs./M2 |

11,000 lbs./M2 |

11,000 lbs./M2 |

11,000 lbs./M2 |

11,000 lbs./M2 |

11,000 lbs./M2 |

|

Rapid Traverse (XYZ) |

394 IPM (787 opt.) |

394 IPM (787 opt.) |

394 IPM (787 opt.) |

394 IPM (787 opt.) |

394 IPM (787 opt.) |

394 IPM (787 opt.) |

|

CNC Control |

Fanuc Oi-MF Plus or |

Fanuc Oi-MF Plus or |

Fanuc Oi-MF Plus or |

Fanuc Oi-MF Plus or |

Fanuc Oi-MF Plus or |

Fanuc Oi-MF Plus or |

|

Spindle Taper |

CAT-50 (BT-50 opt.) |

CAT-50 (BT-50 opt.) |

CAT-50 (BT-50 opt.) |

CAT-50 (BT-50 opt.) |

CAT-50 (BT-50 opt.) |

CAT-50 (BT-50 opt.) |

|

Spindle Speed |

6,000 RPM (up to 15,000 opt.) |

6,000 RPM (up to 15,000 opt.) |

6,000 RPM (up to 15,000 opt.) |

6,000 RPM (up to 15,000 opt.) |

6,000 RPM (up to 15,000 opt.) |

6,000 RPM (up to 15,000 opt.) |

|

Spindle Motor |

35 HP (50 HP opt.) |

35 HP (50 HP opt.) |

35 HP (50 HP opt.) |

35 HP (50 HP opt.) |

35 HP (50 HP opt.) |

35 HP (50 HP opt.) |

|

Spindle Drive |

2 Speed Gearbox |

2 Speed Gearbox |

2 Speed Gearbox |

2 Speed Gearbox |

2 Speed Gearbox |

2 Speed Gearbox |

|

ATC Capacity |

40 (60/80/120 opt.) |

40 (60/80/120 opt.) |

40 (60/80/120 opt.) |

40 (60/80/120 opt.) |

40 (60/80/120 opt.) |

40 (60/80/120 opt.) |

|

Weight (est. base only) |

120,000 lbs. |

142,000 lbs. |

170,000 lbs. |

220,000 lbs. |

240,000 lbs. |

260,000 – 300,000 lbs.+ |

| Item / Model |

SDMC-5000x1800-5000+5F

Request a Quote |

SDMC-6000×1800-6000+5F

Request a Quote |

SDMC-7000x2800-6000+5F

Request a Quote |

SDMC-8000x2800-6000+5F

Request a Quote |

SDMC-9000x2800-6000+5F

Request a Quote |

SDMC-10000-25000×1800-6000+5F

Request a Quote |

|---|---|---|---|---|---|---|

|

X Travel |

197″ |

236″ |

275″ |

315″ |

354″ |

394″ – 984″ |

|

Y Travel |

102″ – 228″ |

102″ – 268″ |

102″ – 268″ |

102″ – 268″ |

102″ – 268″ |

102″ – 268″ |

|

Z Travel |

42″ (48″/60″ opt.) |

42″ (48″/60″ opt.) |

42″ (48″/60″ opt.) |

42″ (48″/60″ opt.) |

42″ (48″/60″ opt.) |

42″ (48″/60″ opt.) |

|

Distance Between Columns |

71″ – 158″ |

71″ – 236″ |

71″ – 236″ |

71″ – 236″ |

71″ – 236″ |

71″ – 236″ |

|

W Axis (opt.) |

39.4″ – 78.7″ |

39.4″ – 78.7″ |

39.4″ – 78.7″ |

39.4″ – 78.7″ |

39.4″ – 78.7″ |

39.8″ – 78.7″ |

|

Table Size |

197″ x 52″ – 197″ x 138″ |

236″ x 51″ – 236″ x 138″ |

275″ x 87″ – 138″ |

315″ x 87 – 134″ |

354″ x 87 – 134″ |

394″ x 138″ |

|

Table Load |

11,000 lbs./M2 |

11,000 lbs./M2 |

11,000 lbs./M2 |

11,000 lbs./M2 |

11,000 lbs./M2 |

11,000 lbs./M2 |

|

Rapid Traverse (XYZ) |

394 IPM (787 opt.) |

394 IPM (787 opt.) |

394 IPM (787 opt.) |

394 IPM (787 opt.) |

394 IPM (787 opt.) |

394 IPM (787 opt.) |

|

CNC Control |

Fanuc Oi-MF Plus or |

Fanuc Oi-MF Plus or |

Fanuc Oi-MF Plus or |

Fanuc Oi-MF Plus or |

Fanuc Oi-MF Plus or |

Fanuc Oi-MF Plus or |

|

Automatic Attachment |

2 – 4 Positions |

2 – 4 Positions |

2 – 4 Positions |

2 – 4 Positions |

2 – 4 Positions |

2 – 4 Positions |

|

5-Face Index |

1, 2.5, 5 Degrees |

1, 2.5, 5 Degrees |

1, 2.5, 5 Degrees |

1, 2.5, 5 Degrees |

1, 2.5, 5 Degrees |

1, 2.5, 5 Degrees |

|

Spindle Taper |

CAT-50 (BT-50 opt.) |

CAT-50 (BT-50 opt.) |

CAT-50 (BT-50 opt.) |

CAT-50 (BT-50 opt.) |

CAT-50 (BT-50 opt.) |

CAT-50 (BT-50 opt.) |

|

Spindle Speed |

6,000/2,000 RPM |

6,000/2,000 RPM |

6,000/2,000 RPM |

6,000/2,000 RPM |

6,000/2,000 RPM |

6,000/2,000 RPM |

|

Spindle Motor |

35 HP (50 opt.) |

35 HP (50 opt.) |

35 HP (50 opt.) |

35 HP (50 opt.) |

35 HP (50 opt.) |

35 HP (50 opt.) |

|

Spindle Drive |

2 Speed Gearbox |

2 Speed Gearbox |

2 Speed Gearbox |

2 Speed Gearbox |

2 Speed Gearbox |

2 Speed Gearbox |

|

ATC Capacity |

40 (60/80/120 opt.) |

40 (60/80/120 opt.) |

40 (60/80/120 opt.) |

40 (60/80/120 opt.) |

40 (60/80/120 opt.) |

40 (60/80/120 opt.) |

|

Weight (est. base only) |

120,000 – 160,000 lbs. |

140,000 – 175,000 lbs. |

140,000 – 175,000 lbs. |

200,000 lbs. |

175,000 – 264,000 lbs. |

212,000 – 300,000 lbs.+ |

| Item / Model |

SDMC-5000x1800-5000+5A

Request a Quote |

SDMC-6000×1800-6000+5A

Request a Quote |

SDMC-7000x2800-6000+5A

Request a Quote |

SDMC-8000x2800-6000+5A

Request a Quote |

SDMC-9000x2800-6000+5A

Request a Quote |

SDMC-10000-25000×2800-6000+5A

Request a Quote |

|---|---|---|---|---|---|---|

|

X Travel |

197″ |

236″ |

275″ |

315″ |

354″ |

394″ – 984″ |

|

Y Travel |

102″ – 228″ |

102″ – 268″ |

102″ – 268″ |

102″ – 268″ |

102″ – 268″ |

102″ – 268″ |

|

Z Travel |

42″ (48″/60″ opt.) |

42″ (48″/60″ opt.) |

42″ (48″/60″ opt.) |

42″ (48″/60″ opt.) |

42″ (48″/60″ opt.) |

42″ (48″/60″ opt.) |

|

Distance Between Columns |

71″ – 158″ |

71″ – 236″ |

71″ – 236″ |

71″ – 236″ |

71″ – 236″ |

71″ – 236″ |

|

W Axis (opt.) |

39.4″ – 78.7″ |

39.4″ – 78.7″ |

39.4″ – 78.7″ |

39.4″ – 78.7″ |

39.4″ – 78.7″ |

39.8″ – 78.7″ |

|

Table Size |

197″ x 52″ – 138″ |

236″ x 52″ – 138″ |

275″ x 87″ – 138″ |

315″ x 87″ – 138″ |

354″ x 87″ – 138″ |

394″ x 87″ – 138″ |

|

Table Load |

11,000 lbs./M2 |

11,000 lbs./M2 |

11,000 lbs./M2 |

11,000 lbs./M2 |

11,000 lbs./M2 |

11,000 lbs./M2 |

|

Rapid Traverse (XYZ) |

394 IPM (787 opt.) |

394 IPM (787 opt.) |

394 IPM (787 opt.) |

394 IPM (787 opt.) |

394 IPM (787 opt.) |

394 IPM (787 opt.) |

|

CNC Control |

Fanuc 31i-MB Plus or 31i-MB5 Plus |

Fanuc 31i-MB Plus or 31i-MB5 Plus |

Fanuc 31i-MB Plus or 31i-MB5 Plus |

Fanuc 31i-MB Plus or 31i-MB5 Plus |

Fanuc 31i-MB Plus or 31i-MB5 Plus |

Fanuc 31i-MB Plus or 31i-MB5 Plus |

|

ATC Capacity |

40 (60/80/120 opt.) |

40 (60/80/120 opt.) |

40 (60/80/120 opt.) |

40 (60/80/120 opt.) |

40 (60/80/120 opt.) |

40 (60/80/120 opt.) |

|

TU-35 Heavy-Duty | ||||||

|

Spindle Taper |

CAT-50 (HSK-100A opt.) |

CAT-50 (HSK-100A opt.) |

CAT-50 (HSK-100A opt.) |

CAT-50 (HSK-100A opt.) |

CAT-50 (HSK-100A opt.) |

CAT-50 (HSK-100A opt.) |

|

Spindle Speed |

4,000 RPM (6,000 opt.) |

4,000 RPM (6,000 opt.) |

4,000 RPM (6,000 opt.) |

4,000 RPM (6,000 opt.) |

4,000 RPM (6,000 opt.) |

4,000 RPM (6,000 opt.) |

|

Spindle Motor |

35 HP (50 opt.) |

35 HP (50 opt.) |

35 HP (50 opt.) |

35 HP (50 opt.) |

35 HP (50 opt.) |

35 HP (50 opt.) |

|

Spindle Drive |

2 Speed Gearbox |

2 Speed Gearbox |

2 Speed Gearbox |

2 Speed Gearbox |

2 Speed Gearbox |

2 Speed Gearbox |

|

AC-52 High-Speed | ||||||

|

Spindle Taper |

HSK-100A (HSK-63A opt.) |

HSK-100A (HSK-63A opt.) |

HSK-100A (HSK-63A opt.) |

HSK-100A (HSK-63A opt.) |

HSK-100A (HSK-63A opt.) |

HSK-100A (HSK-63A opt.) |

|

Spindle Speed |

10,000 RPM (24,000 opt.) |

10,000 RPM (24,000 opt.) |

10,000 RPM (24,000 opt.) |

10,000 RPM (24,000 opt.) |

10,000 RPM (24,000 opt.) |

10,000 RPM (24,000 opt.) |

|

Spindle Drive |

Integral Motor |

Integral Motor |

Integral Motor |

Integral Motor |

Integral Motor |

Integral Motor |

|

Spindle Motor |

52 HP |

52 HP |

52 HP |

52 HP |

52 HP |

52 HP |

|

Weight (est. base only) |

120,000 – 160,000 lbs. |

140,000 – 175,000 lbs. |

140,000 – 175,000 lbs. |

150,000 – 200,000 lbs. |

175,000 – 264,000 lbs. |

212,000 – 300,000 lbs.+ |

3 Axis Standard Accessories

5 Face Standard Accessories

5 Axis Standard Accessories

3 Axis Options

5 Face Options

5-Axis Options

5-Face Heads

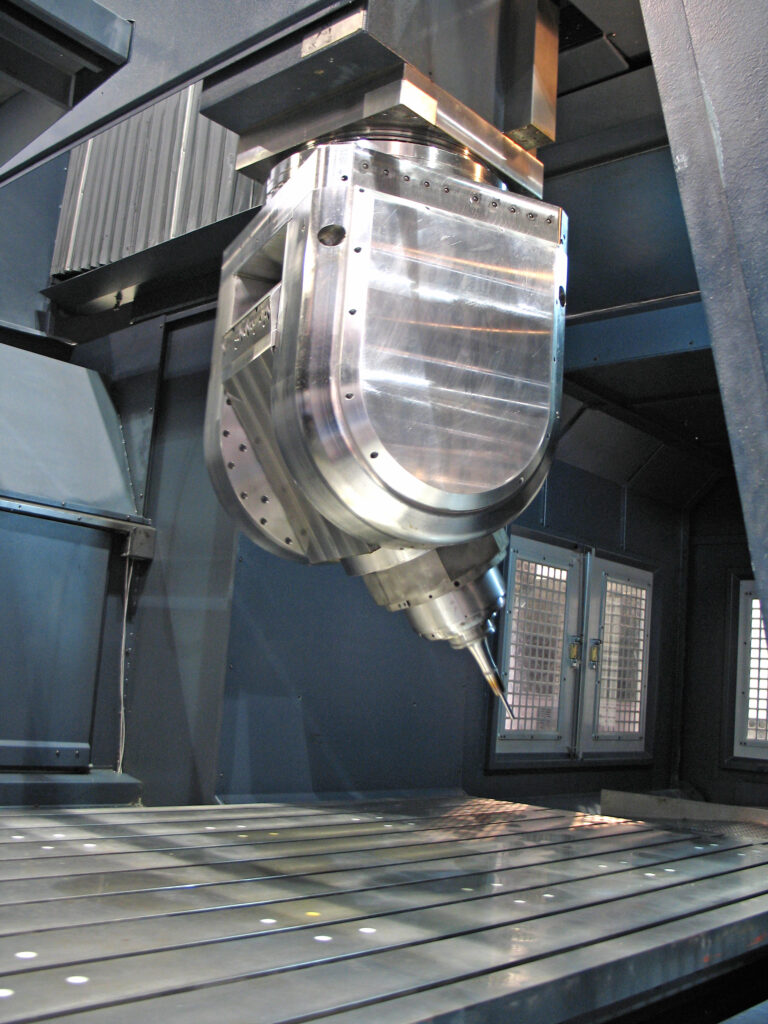

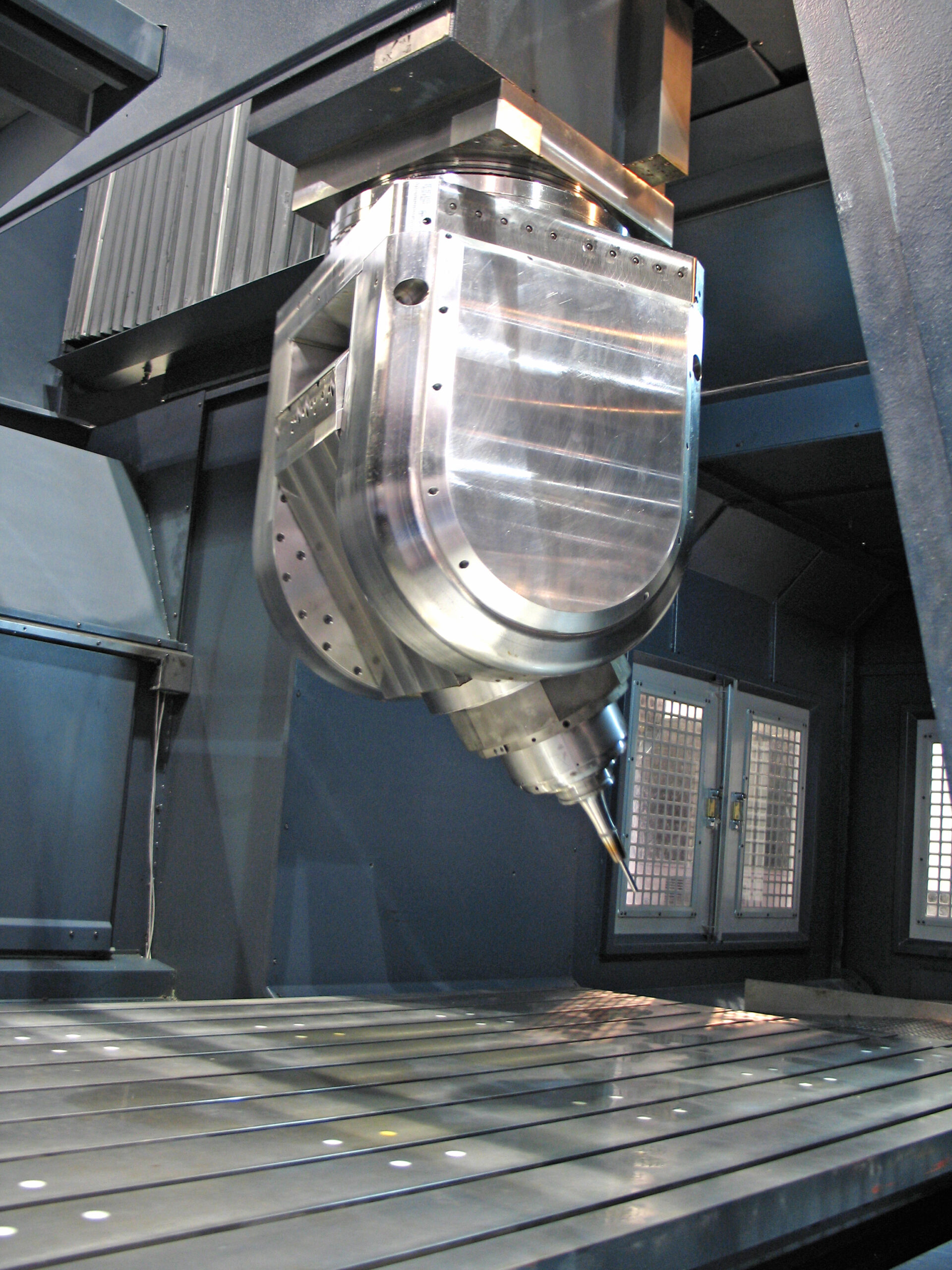

5-Axis / 2-Axis NC Heads

FAQs

Can you customize X,Y, and Z travels in the Johnford DMC series?

Yes, Johnford can build machines in the DMC series with up to 240 inches in x-travel and up to 157 inches in y-travel. Johnford will also customize the DMC series with up to 2 meters of w-axis travel.

What are some examples of common parts made using bridge mills?

Weldments, molds, dies, plate work, forgings

Does Johnford have a full 5-axis head configuration?

Yes, with spindle speeds from 4,000 rpm with a 2-speed gearbox up to 20,000 rpm with an integral spindle motor.

Does the Johnford DMC series offer a solution for high speed and complex 3D machining?

Yes. Johnford offers our DMC Hi-Net series with spindles ranging from 15,000 rpm in an HSK-100A to 24,000 rpm in an HSK-63A with features such as Fanuc 31i-MB control, thermal growth automatic compensation, and Heidenhain linear scales on X, Y, and Z axes.