Johnford FBMC Series CNC Boring Mills

Built-to-Order Ultra-Heavy Floor-Type CNC Boring Mills Engineered for Unlimited Travel, Extreme Rigidity & Application-Specific Customization

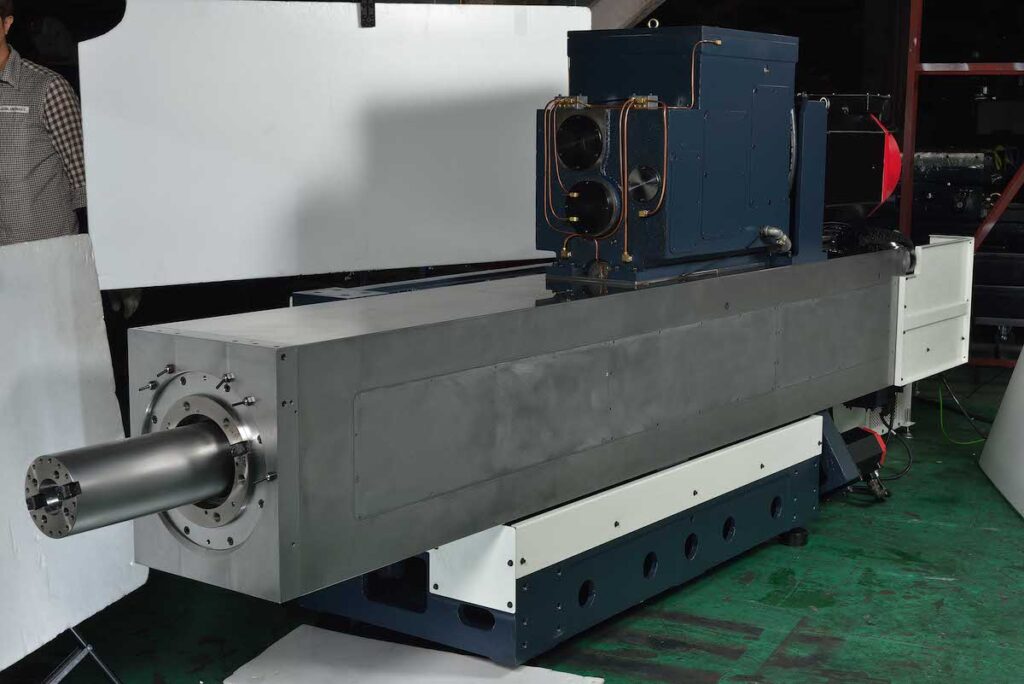

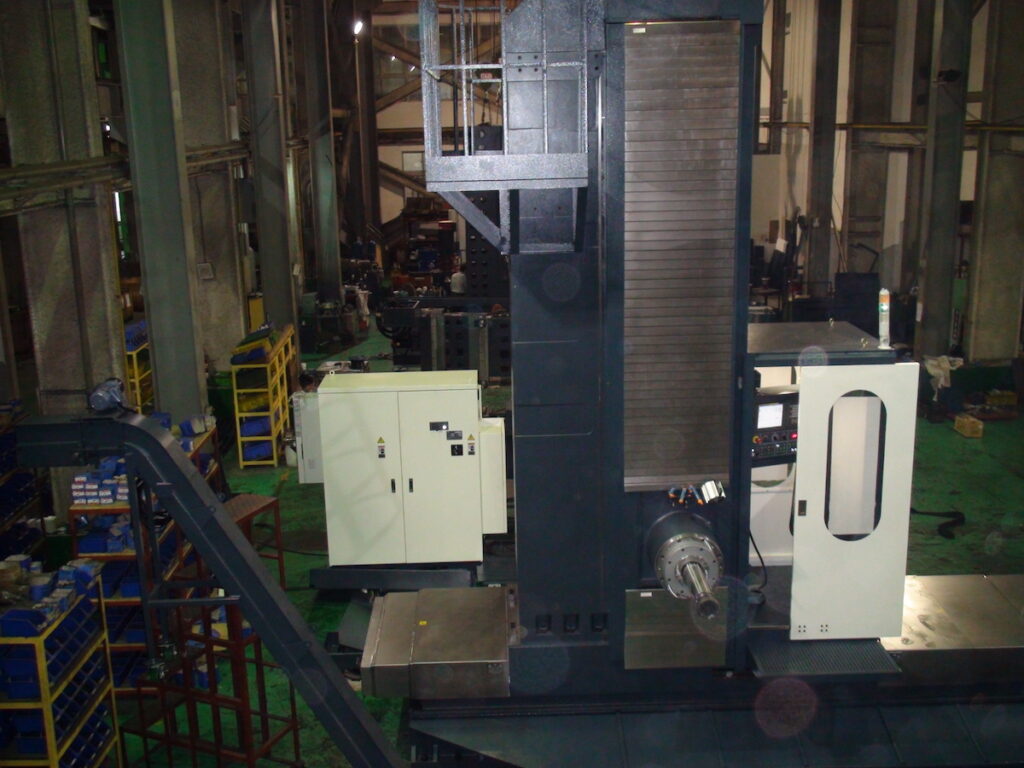

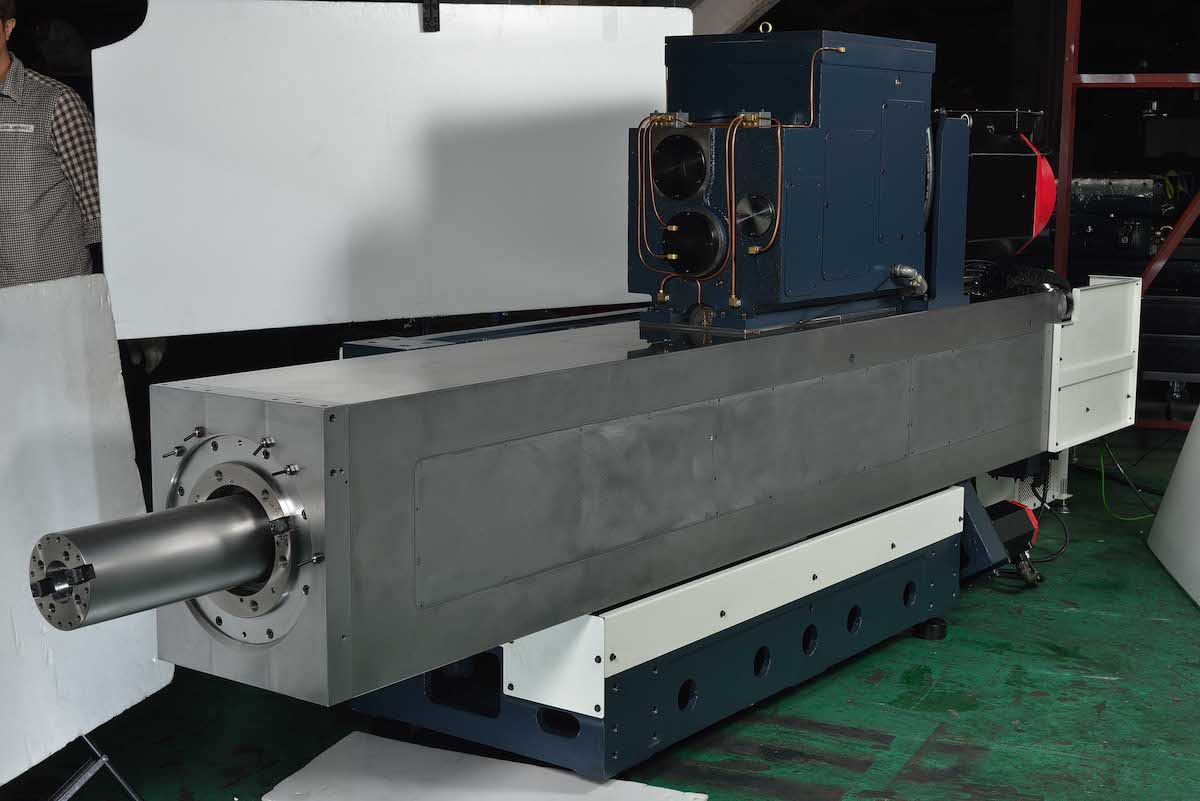

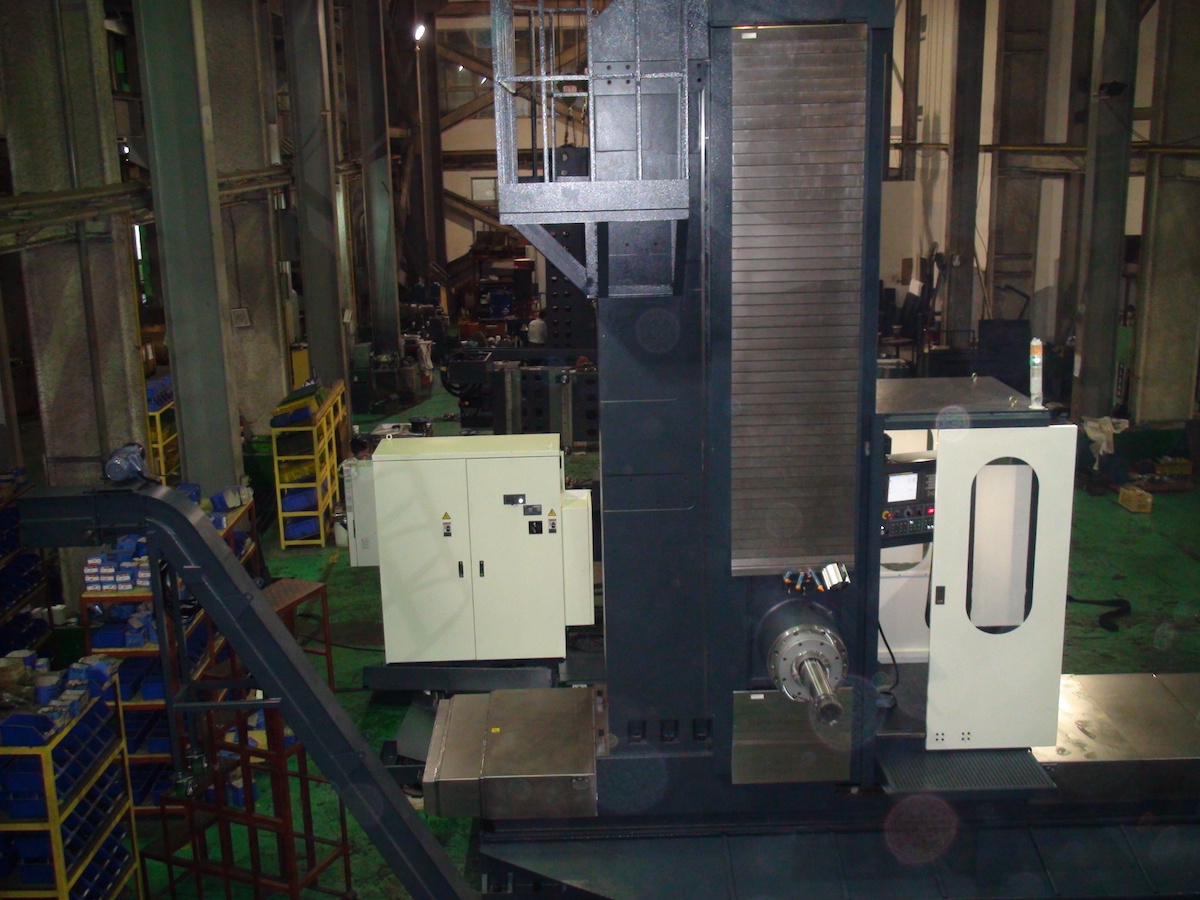

The Johnford FBMC Series represents the pinnacle of floor-type CNC boring mill engineering — purpose-built for manufacturers machining extremely large, heavy, and complex components that demand absolute rigidity and accuracy over long distances. Constructed from massive Meehanite castings (up to 350,000 lbs for large configurations ) and using moving-column X-axis architecture, these boring milling machines deliver exceptional stability for precision machining of aerospace structures, energy components, industrial equipment bases, heavy machinery frames, wind turbine structures, and multi-surface machining applications involving extremely long travel requirements.

Unlike standard production boring mills, every FBMC machine is custom-engineered to the buyer’s exact application—from X-axis travels as short as 236″ to more than 590″ (15 meters) , to custom floor plates, hydrostatic or roller-bearing rotary tables, extended-travel rams, and full automatic attachment changers. This flexibility positions the FBMC Series as a world-class alternative to much more expensive systems from Fermat, TOS Varnsdorf, and Giddings & Lewis, while delivering equal or greater rigidity and long-term accuracy at a more competitive investment level.

Key Features

- Massive Moving-Column Floor-Type Design

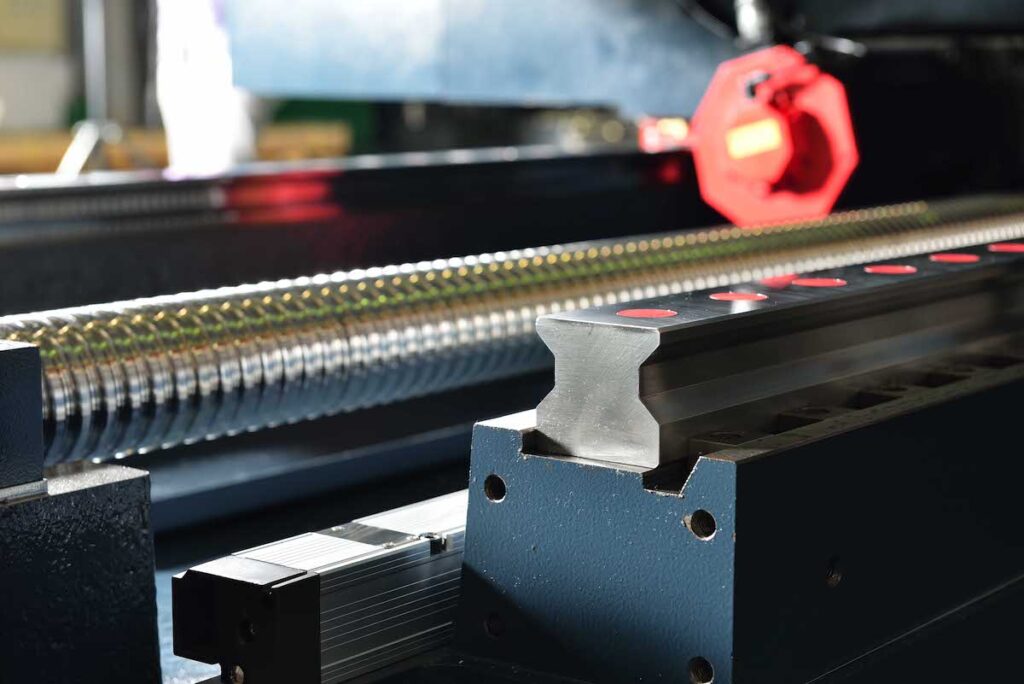

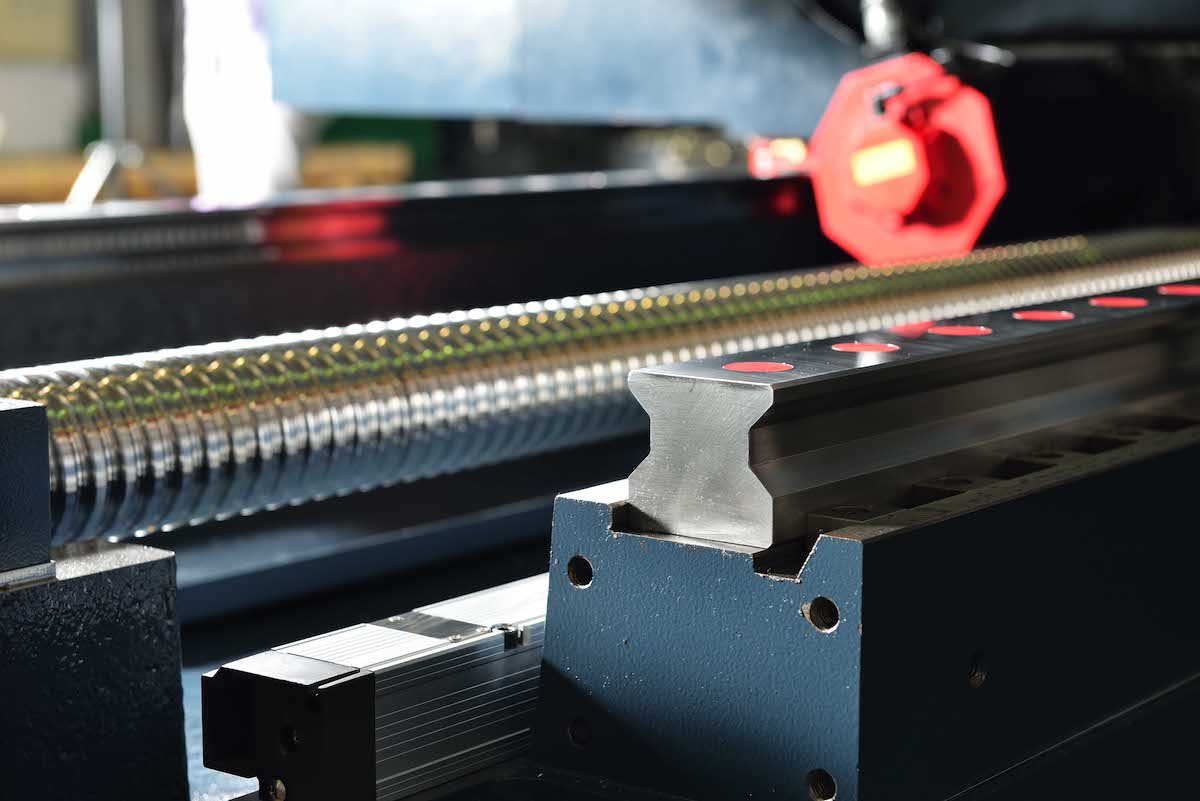

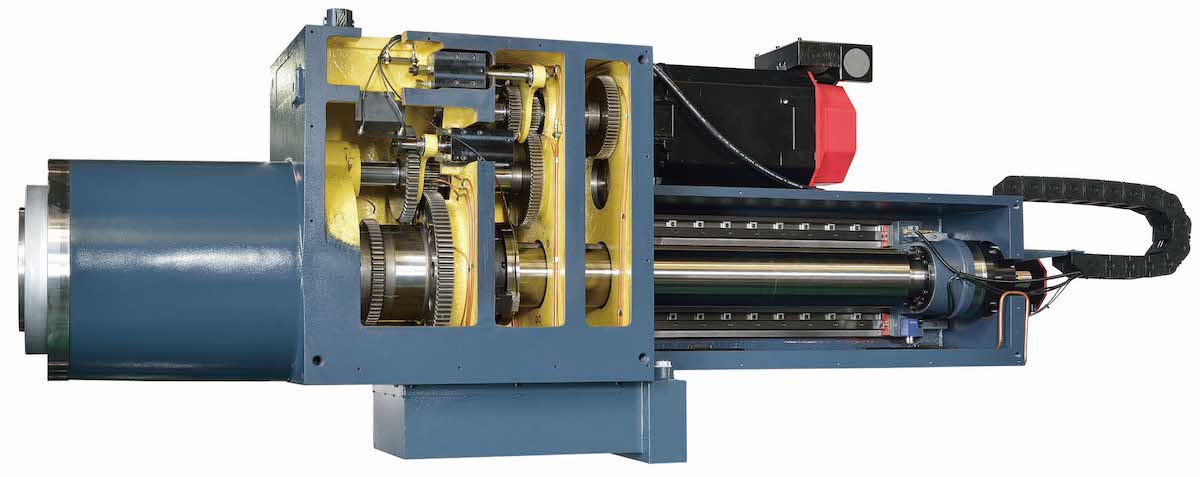

One-piece X-axis base casting with dual rack-and-pinion drive ensures stable movement across travels up to 590″+ (15 meters) while eliminating table overhang. - Hydrostatic Box-Way or Roller-Way Systems

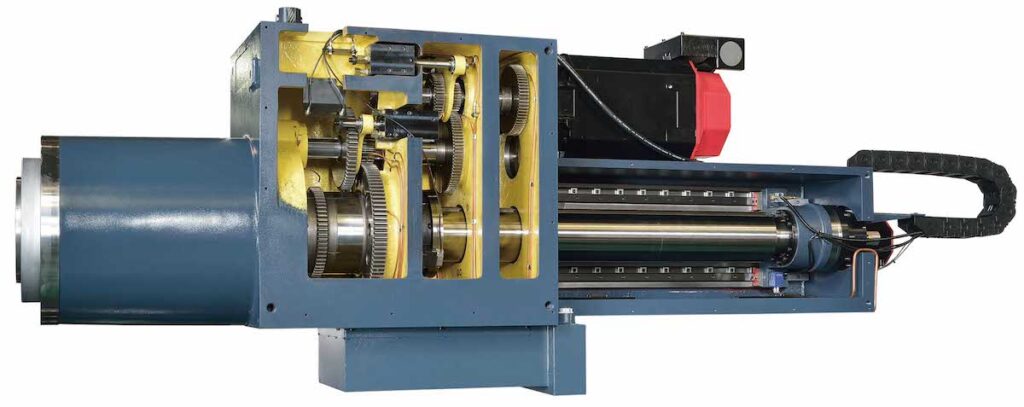

Hydrostatic ways in X/Y/Z/B for ultra-smooth motion, zero metal-to-metal contact, and exceptional long-term accuracy (hydrostatic standard on many large configurations) . - Heavy-Duty 6.3″ Spindle Bar + Massive Ram Construction

Chrome-moly quill and 20.5″ × 17.7″+ ram cross-sections deliver superior rigidity for deep boring and extended-reach cutting at full spindle power. - 100 HP Three-Speed Geared Spindles

High torque at low RPM enables heavy-cut milling, deep boring, and high-load drilling applications. - Customizable Table Configurations

- Fixed floor plates of 6m, 10m, 14m, or 15m length

- Roller-bearing rotary tables up to 55,000 lbs

- Hydrostatic rotary tables up to 110,000 lbs with V-axis travel

- Combination fixed + rotary table systems

(All configurations documented across supplied quotations.)

- Automatic Attachment Changer (Optional)

Supports 1–4 heads including right-angle, 2-axis indexing, extension heads, and more for complex multi-directional machining. - 60–120 Tool ATC with Column-Mounted Design

Heavy-duty arm-type ATC travels with the column for fast tool changes and maintenance access. - Advanced Axis Control and Feedback

Heidenhain linear scales on all axes (XYZWV) ensure long-travel accuracy and thermal stability across massive machine structures. - Fanuc 31iM-B Plus Control System

High-performance CNC with Manual Guide i, AICC-II contouring, 1,000,000-pulse encoders, and multi-axis simultaneous control for mold-and-die and complex surfacing. - Integrated Chip & Coolant Management

Caterpillar conveyors, 250–500 gallon coolant capacity, programmable air blast, and 300 PSI TSC maintain stable cutting conditions for long-cycle operations. - Operator-Friendly Elevated Cabin

Operator platforms provide clear line-of-sight to machining zones on machines of this magnitude.

Specifications

| Item / Model |

FBMC-160

Request a Quote

|

|---|---|

|

X Axis Travel |

236″ – (up to 591″ and beyond) |

|

Y Axis Travel |

137.80″ – 196.85″ |

|

Z Axis Travel |

47.24″ |

|

W Axis Travel |

39.37″ |

|

V Axis Travel |

78.74″ |

|

Ram Cross Section |

17.72″ x 20.47″ |

|

Spindle Bar |

6.3″ |

|

Table Size Length |

275.59″ – 393.70″ |

|

Table Size Width |

98.43″ |

|

Table Loading Capacity |

1024 lbs/sq. ft. |

|

Max. Workpiece Load Flat Table |

2,200 lbs./sq.ft. |

|

Spindle HP |

100 HP |

|

Spindle Speed |

10 – 2,200 RPM |

|

Spindle Nose Taper |

CAT-50 |

|

Spindle Drive Motor |

80/100 HP |

|

Spindle Drive Motor (S1/S6 – 60%) |

60 /75 kW |

|

Spindle Drive |

3 Speed Gearbox |

|

X/Y/Z/W/V Axis Rapid Traverse |

X=630.4 / Y,Z,V=472.8 / W=236.4 IPM |

|

X/Y/Z/W/V Axis Cutting Feed Rate |

1 – 236.22 IPM |

|

X/Y/Z/W/V Axis Servo Motor (HP) |

X=12 / Y=8 / Z,W,V=9 |

|

ATC Capacity |

60 (80/120 opt.) |

|

ATC Max Tool Diameter |

∅9.84″ |

|

ATC Max Tool Length |

15.75″ |

|

ATC Max Tool Mass |

55 lbs. |

|

ATC Max Tool Dia. of Full Setting |

∅4.92″ |

|

ATC Tool Selection |

Bi-Direction Random Type, Shortest Path |

|

Pneumatic Pressure |

85 PSI |

|

Rotary Table Size |

98.43″ x 118.11″ |

|

Rotary Table Capacity |

55,000 lbs. (100,000 opt.) |

|

Machine Length (in.) |

799.21 – 917.32 |

|

Machine Width (in.) |

564.96 |

|

Machine Height (in.) |

230.31 – 289.37 |

|

CNC Control Type |

FANUC 31iMB |

|

Weight (lbs.) |

240,000 – 349,800 (est. weights increase |

Optional Control Features – Fanuc 31iM-B

Benefits for Metal Cutting Manufacturers

The Johnford FBMC Series provides unmatched machine stability, axis rigidity, and long-travel precision for manufacturers who must maintain micron-level accuracy across massive work envelopes. These floor-type CNC boring machines solve critical production challenges by enabling long-part machining, multi-side access, deep boring, heavy milling, and multi-axis positioning on parts too large for table-type boring mills.

Key manufacturing advantages include:

- Extreme stability for ultra-large components

Base machine weights of 200,000–350,000 lbs (depending on configuration) deliver exceptional vibration damping and stable cutting forces even during heavy-duty roughing operations . - Long-travel precision with hydrostatic or roller-way systems

Hydrostatic box-way systems in X/Y/Z/B provide near-zero wear, friction-free movement, and ±0.0003″/meter positioning accuracy for very long machining distances . - Superior accuracy on tall and heavy workpieces

Ram designs as large as 21.65″ × 18.9″ and 6.3″ hardened quill bars provide ideal rigidity for deep-reach boring, ram-type milling, and multi-face machining on tall structures . - High spindle torque for demanding heavy-cut applications

100 HP gear-driven spindles delivering up to 6,098 ft-lbs of torque at 87 RPM ensure reliable machining of high-strength alloys and massive components . - Massive, customizable rotary and fixed tables

Rotary tables up to 118″ × 118″ with hydrostatic or roller-bearing systems support loads up to 110,000 lbs, while fixed floor plates can span 6–15 meters or more, allowing complete machining of oversized structures . - Seamless automation with attachment changers and probing

Optional automatic attachment changers (AAC) and tool probe packages enable multi-face machining and reduced manual setups—critical for aerospace, energy, and large-part OEMs. - Reduced cycle times and multi-surface efficiency

High-speed dual rack-and-pinion drives on X and rapid rates up to 590 IPM enable fast positioning across long travels without compromising accuracy .

For manufacturers producing large structural components, precision bases, wind turbine components, power-generation housings, aerospace fixtures, and heavy steel weldments, the FBMC Series offers unmatched accuracy, rigidity, cycle-time efficiency, and application-specific configurability unavailable in standard boring mills.

Ideal Cutting Applications

- Aerospace structures

Large fixtures, wing ribs, landing gear components, bulkheads, spars, fuselage frames, and multi-face aluminum/steel structures. - Energy & power-generation components

Turbine housings, generator frames, wind turbine hubs and bases, compressor housings, heat-exchanger bodies. - Heavy industry & machinery bases

Machine tool bases, precision ways, welded frames, press plates, structural beams, and large cast iron or fabricated components. - Oil & gas / defense

Valve bodies, drilling housings, missile frames, armored vehicle components, and large-diameter precision bores. - Large mold & die manufacturing

Deep cavities, long-reach core machining, large die bases, multi-surface 5-side machining using B-axis rotary positioning. - Transportation & rail equipment

Bogie frames, axle housings, structural load-bearing components requiring precision boring and milling. - Oversized fabricated structures

Weldments, steel frames, construction equipment components, wind tower sections, and any long, heavy, or tall part requiring custom CNC boring capability.