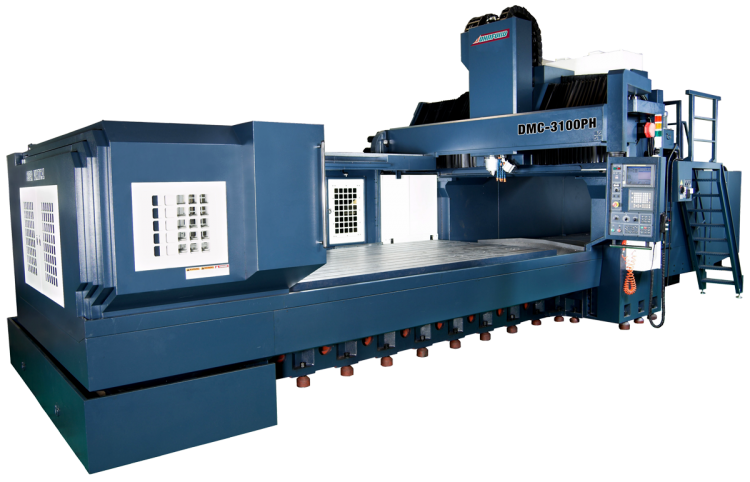

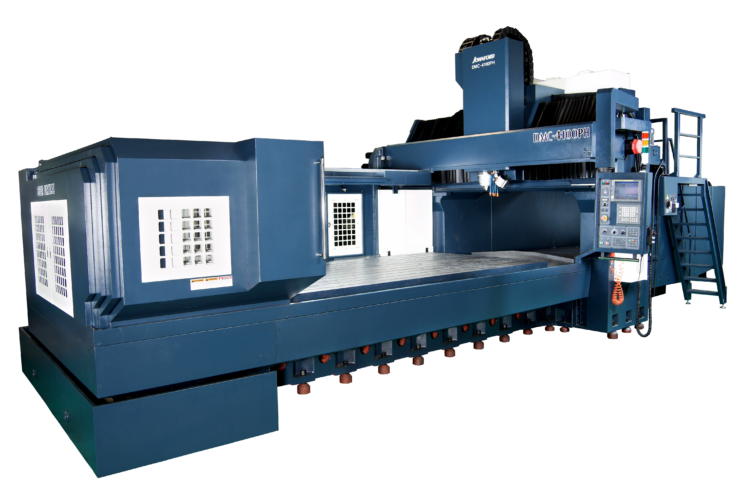

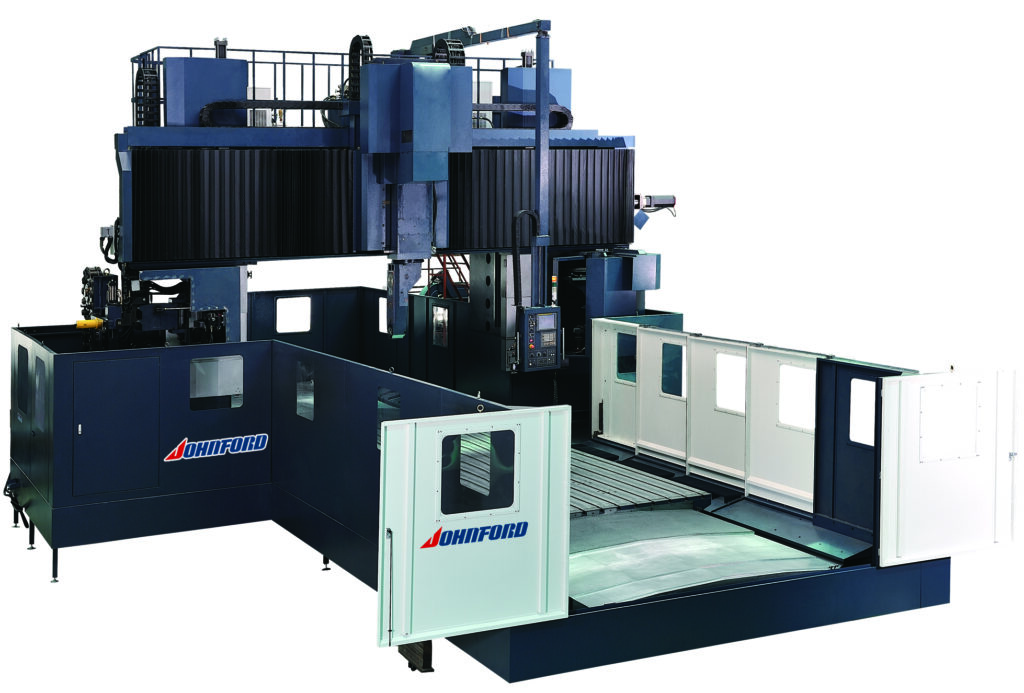

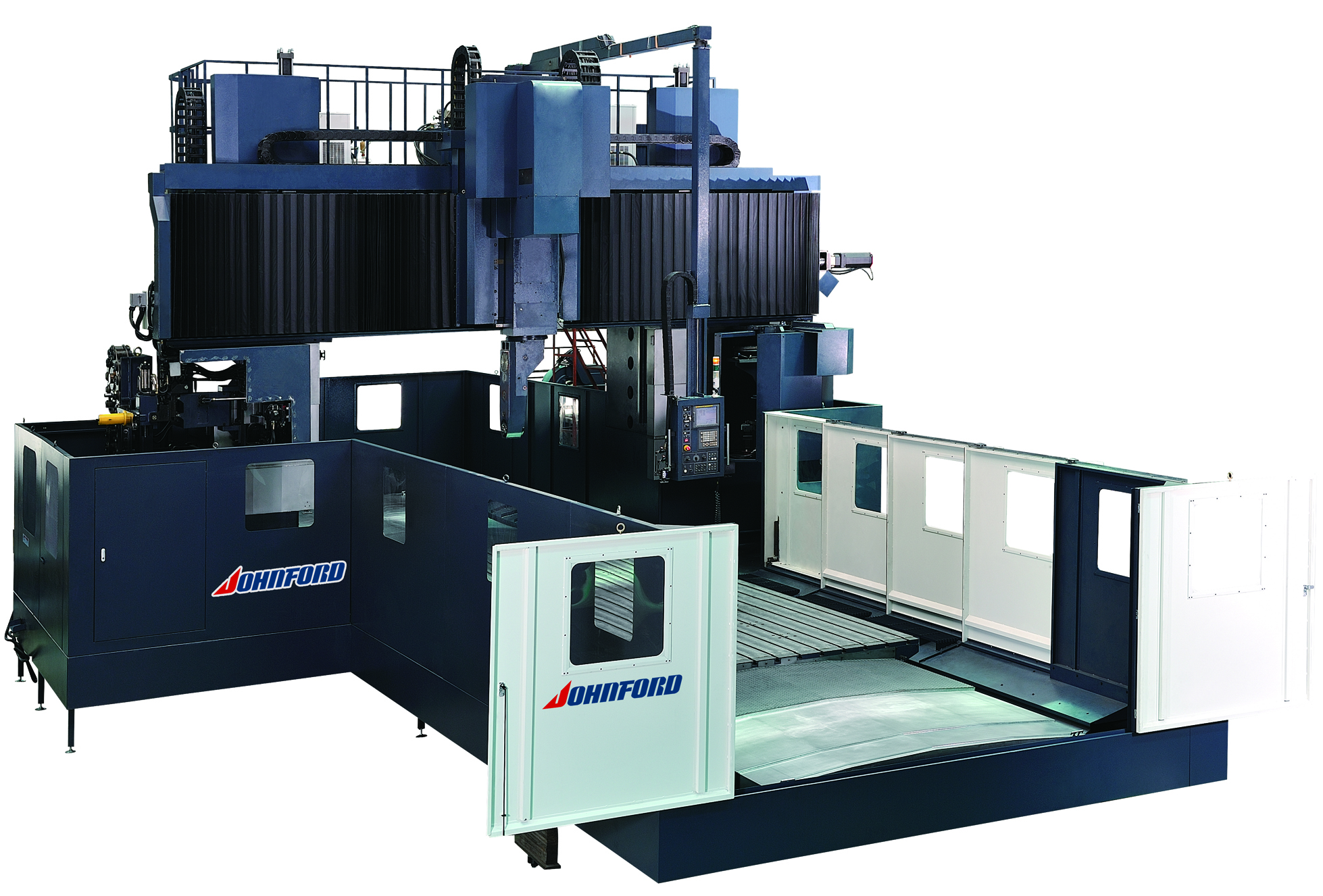

DMC P/PH Series 3100mm – 6100mm with 2300mm (90.5″) Extended Y-Axis Travel

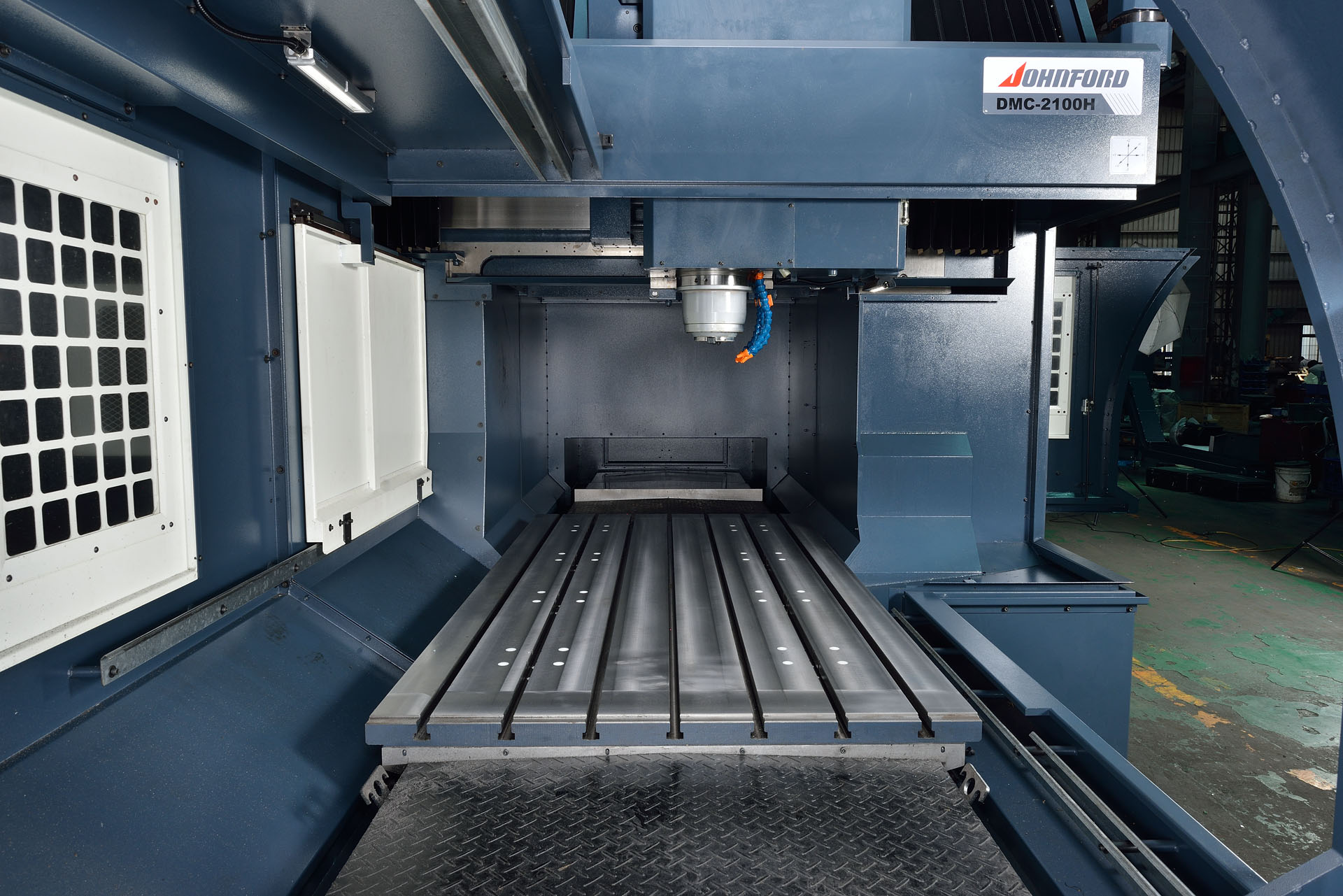

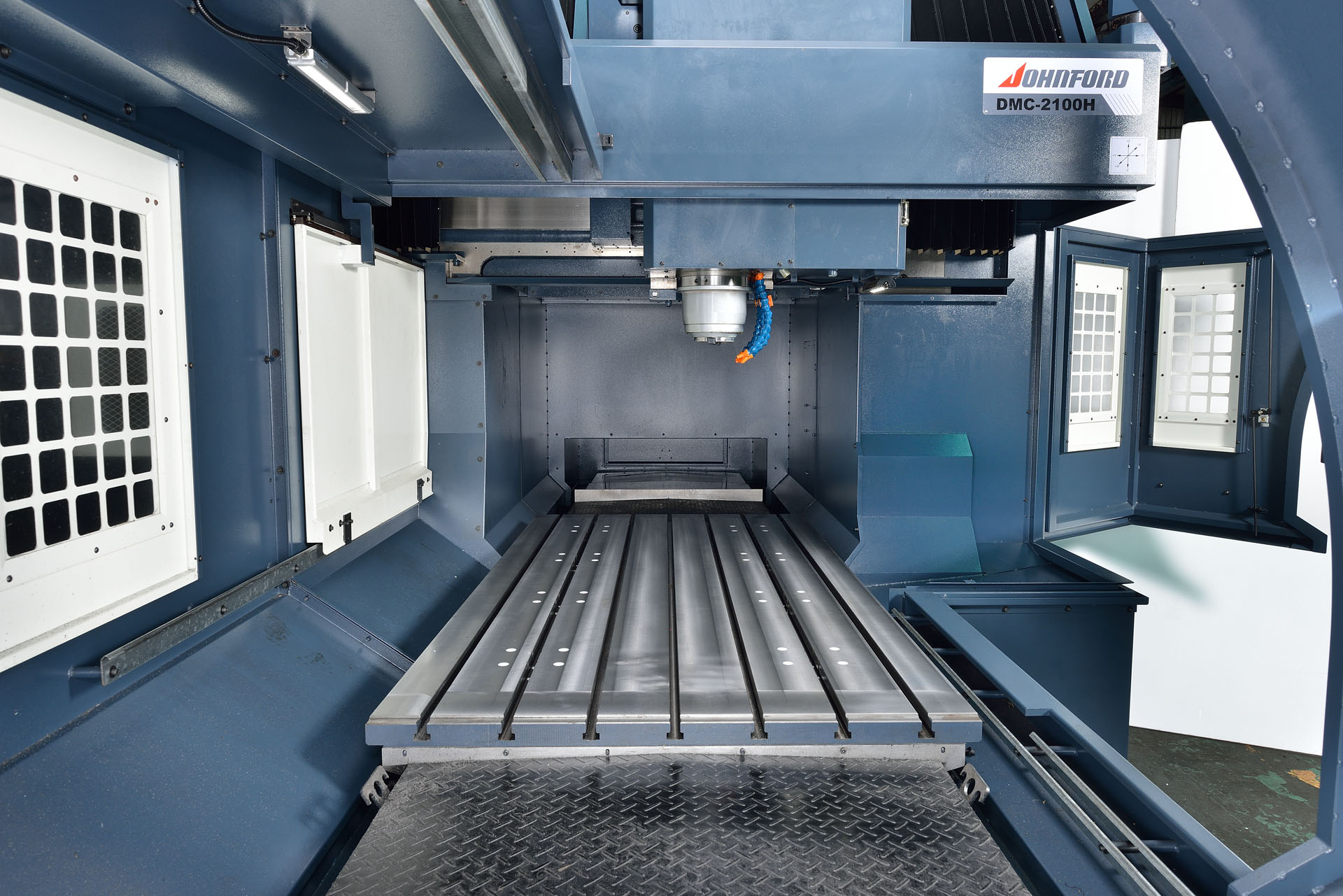

Johnford’s PH Series CNC bridge mills deliver exceptional capacity and precision for large-part machining with an extended Y-axis travel of 2300 mm (90.5″). Built to handle the demands of heavy-duty cutting while maintaining accuracy, the PH Series features an extra-heavy, one-piece Meehanite cast structure with 650 mm (25.6″) widely spaced box ways and 880 mm (34.6″) roller linear guideway spacing for outstanding rigidity. This robust design ensures stable, repeatable performance in demanding industrial applications.

Looking for a different size/capability? Check out other models in the DMC Series:

Engineered for Rugged Performance and Clean Operation

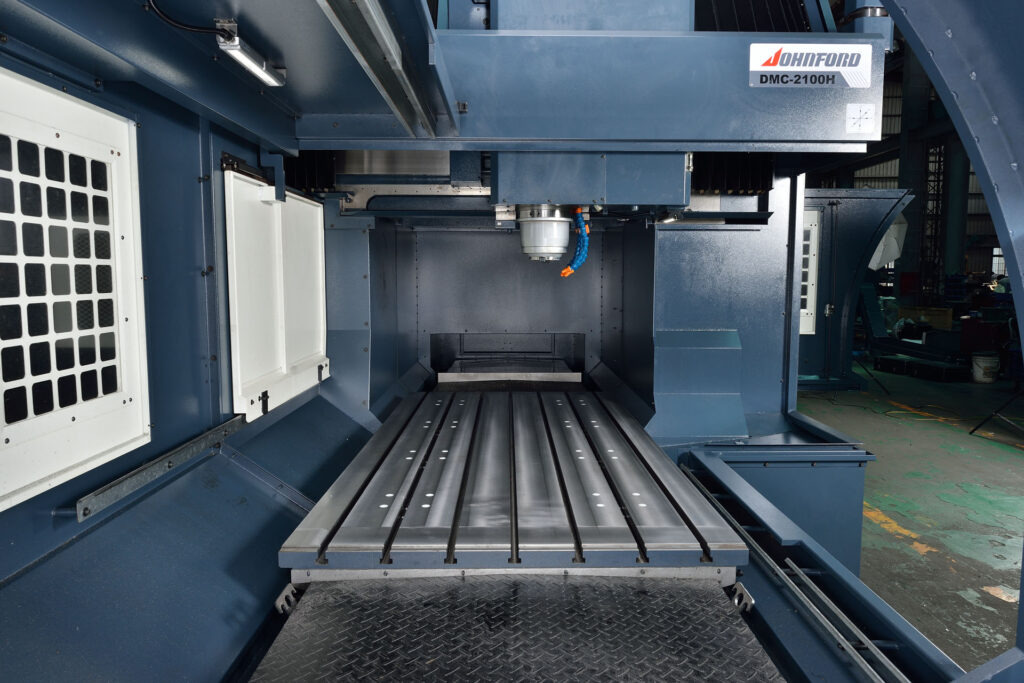

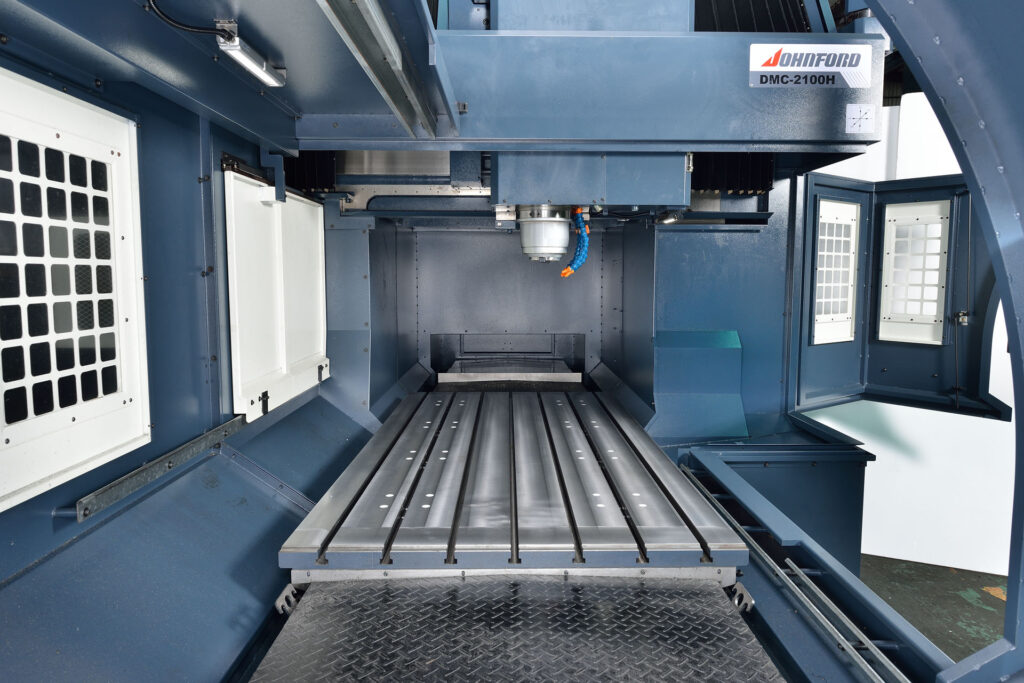

The PH Series Y-axis rides in a fully enclosed carriage that protects box ways and linear guideways from contamination or accidental damage, maintaining machining accuracy and ensuring a clean, operator-friendly work area with efficient chip flushing. As machine size and capability increase, Johnford integrates advanced options such as full 5-face and 5-axis machining heads. To support these larger travels and cutting forces, the bridge, columns, and headstock castings are significantly reinforced over smaller series, staying true to Johnford’s hallmark of robust engineering while retaining superior ergonomics and enclosure design.

Precision Components for Demanding Applications

All box ways — including the optional extended-travel Z-axis (available in 42″ and 48″ configurations) — are precision-ground and Turcite-B coated for smooth movement and long-lasting durability. Powerful servo motors deliver maximum thrust: 6 kW on the X-axis and 7 kW on the Y-axis ensure efficient positioning under heavy loading. Extra-large diameter ballscrews further improve positional accuracy, with dimensions of 70 mm in X, 63 mm in Y, and 50 mm in Z. For even more versatility, the PH Series can be configured with optional 5-face and 5-axis machining heads or customized to meet unique production needs.

Key Features:

Ideal for:

Need a customized-size CNC Bridge Mill?

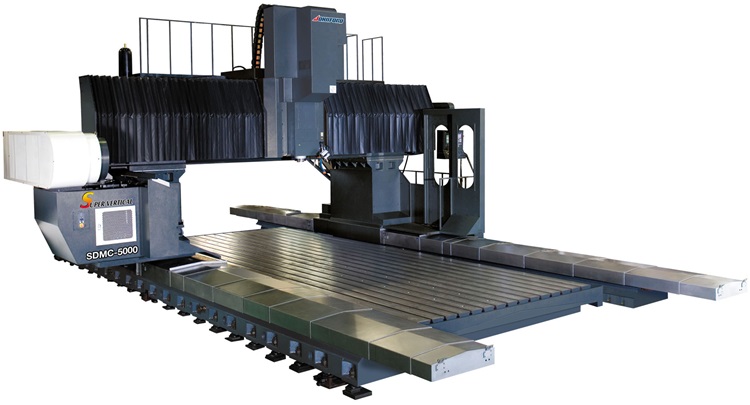

Johnford prides itself on offering countless customized sizes and payload designs in both DMC moving table / fixed column designs and SDMC sliding column / fixed table designs.

Get a Quote or Learn More

Ready to add unmatched large-part capacity and precision to your shop?

Contact us today for pricing, demos, or expert advice.

Specifications

| Item / Model |

DMC-3100P

Request a Quote

|

DMC-3100PH

Request a Quote

|

DMC-4100P

Request a Quote

|

DMC-4100PH

Request a Quote

|

DMC-5100P

Request a Quote

|

DMC-5100PH

Request a Quote

|

DMC-6100P

Request a Quote

|

DMC-6100PH

Request a Quote

|

|---|---|---|---|---|---|---|---|---|

|

X Axis Travel |

122″ |

122″ |

161.4″ |

161.4″ |

200.8″ |

200.8″ |

240.1″ |

240.1″ |

|

Y Axis Travel |

90.5″ |

90.5″ |

90.5″ |

90.5″ |

90.5″ |

90.5″ |

90.5″ |

90.5″ |

|

Z Axis Travel |

31.5″ (42″ opt.) |

31.5″ (42″ opt.) |

31.5″ (42″ opt.) |

31.5″ (42″ opt.) |

31.5″ (42″ opt.) |

31.5″ (42″ opt.) |

31.5″ (42″ opt.) |

31.5″ (42″ opt.) |

|

W Axis Travel (opt.) |

39.4″/59.1″/78.7″ |

39.4″/59.1″/78.7″ |

39.4″/59.1″/78.7″ |

39.4″/59.1″/78.7″ |

39.4″/59.1″/78.7″ |

39.4″/59.1″/78.7″ |

39.4″/59.1″/78.7″ |

39.4″/59.1″/78.7″ |

|

Distance Between Columns |

94.4″ |

94.4″ |

94.4″ |

94.4″ |

94.4″ |

94.4″ |

94.4″ |

94.4″ |

|

Table Size |

126″ x 80.7″ |

126″ x 80.7″ |

165.3″ x 80.7″ |

165.3″ x 80.7″ |

204.7″ x 80.7″ |

204.7″ x 80.7″ |

244″ x 80.7″ |

244″ x 80.7″ |

|

Table Load |

22,200 lbs. |

22,200 lbs. |

28,600 lbs. |

28,600 lbs. |

26,400 lbs. |

33,000 lbs. |

26,400 lbs. |

26,400 lbs. |

|

Rapids X/Y/Z |

472/472/472 IPM |

472/472/472 IPM |

472/472/472 IPM |

472/472/472 IPM |

472/472/472 IPM |

472/472/472 IPM |

472/472/472 IPM |

472/472/472 IPM |

|

CNC Control |

Oi-MF Plus (31i-MB opt.) |

Oi-MF Plus (31i-MB opt.) |

Oi-MF Plus (31i-MB opt.) |

Oi-MF Plus (31i-MB opt.) |

Oi-MF Plus (31i-MB opt.) |

Oi-MF Plus (31i-MB opt.) |

Oi-MF Plus (31i-MB opt.) |

Oi-MF Plus (31i-MB opt.) |

|

Spindle Taper |

BT-40 / CAT 40 (HSK-63A opt.) |

BT-50 / CAT 50 (HSK-100A opt.) |

BT-40 / CAT 40 (HSK-63A opt.) |

BT-50 / CAT 50 (HSK-100A opt.) |

BT-40 / CAT 40 (HSK-63A opt.) |

BT-50 / CAT 50 (HSK-100A opt.) |

BT-40 / CAT 40 (HSK-63A opt.) |

BT-50 / CAT 50 (HSK-100A opt.) |

|

Spindle RPM |

10,000 (15,000 DD opt.) |

6,000 (8,000/10,000 opt.) |

10,000 (15,000 DD opt.) |

6,000 (8,000/10,000 opt.) |

10,000 (15,000 DD opt.) |

6,000 (8,000/10,000 opt.) |

10,000 (15,000 DD opt.) |

6,000 (8,000/10,000 opt.) |

|

Spindle Motor |

15 HP Hi/Lo Gear |

35 HP Hi/Lo Gear |

15 HP Hi/Lo Gear |

35 HP Hi/Lo Gear |

15 HP Hi/Lo Gear |

35 HP Hi/Lo Gear |

15 HP Hi/Lo Gear |

35 HP Hi/Lo Gear |

|

Spindle Drive |

2 Speed Gearbox |

2 Speed Gearbox |

2 Speed Gearbox |

2 Speed Gearbox |

2 Speed Gearbox |

2 Speed Gearbox |

2 Speed Gearbox |

2 Speed Gearbox |

|

ATC Capacity |

40 (60/80/120 opt.) |

40 (60/80/120 opt.) |

40 (60/80/120 opt.) |

40 (60/80/120 opt.) |

40 (60/80/120 opt.) |

40 (60/80/120 opt.) |

40 (60/80/120 opt.) |

40 (60/80/120 opt.) |

|

Weight |

77,000 lbs. |

77,000 lbs. |

90,200 lbs. |

90,200 lbs. |

100,000 lbs. |

100,000 lbs. |

114,000 lbs. |

114,000 lbs. |