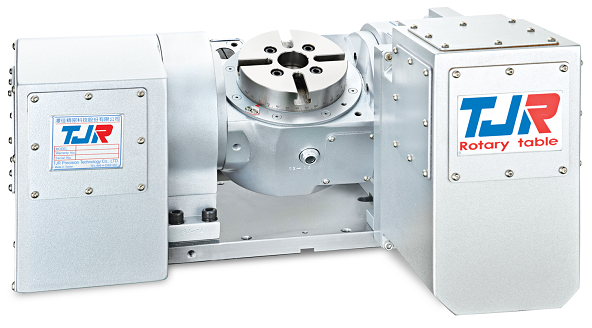

TJR FAR Series – pneumatic brake tilt rotary table

The FAR-Series is TJR’s pneumatic brake tilt rotary table line and is offered in multiple sizes and configurations. The FAR model featured here is TJR’s compact tilt type rotary tables.

This model is offered with a 170mm (6.69”) face plate diameter. The FAR-Series is ideal to convert your traditional 3 axis milling machine into a 5 axis machine for a portion of the cost of a new full 5 axis machine.

They are capable of being fully integrated into your current machine control so you can utilize as a full rotating and tilting axis for true 5 axis work. It is also capable of being used as a full 4th and 5th axis connecting to TJR’s DAC (Dual Axis Controller) in the event that you need to utilize the unit on multiple machine tools.

The FAR series is manufactured with large-diameter radial-axial preloaded bearing system for high rigidity that can perform light or heavy cutting.

Specifications

| Item / Model |

Unit

|

FAR-125/125B

Request a Quote |

FAR-170A (compact type)

Request a Quote |

FAR-170 (Standard type) / FAR-170B (Back side motor type)

Request a Quote |

|---|---|---|---|---|

|

Table Diameter |

mm |

Ø 125 |

Ø 170 |

Ø 170 |

|

Diameter of Table Central Hole |

mm |

Ø 35H7 |

Ø 67 |

Ø 67 |

|

Inner Diameter of Mandrel Sleeve |

mm |

– |

Ø 40H7 |

Ø 40H7 |

|

Diameter of Center Through Hole |

mm |

Ø 25 |

Ø 40 |

Ø 40 |

|

Table Height (Horizontal) |

mm |

215 |

245 |

270 |

|

Table T-slot Width |

mm |

12H7 |

12H7 |

12H7 |

|

Guide Block Width |

mm |

14h7 |

18h7 |

18h7 |

|

Axis (Rotation) | ||||

|

Min. Increment |

deg. |

0.001 |

0.001 |

0.001 |

|

Indexing Precision |

sec. |

40 |

20 |

20 |

|

Repeatability |

sec. |

4 |

4 |

4 |

|

Clamping System (Pneumatic) |

kg/cm2 |

5 |

6 |

6 |

|

Clamping Torque |

kg-m |

13 |

31 |

31 |

|

Servo Motor Model (FANUC) |

Taper/Straight shaft |

α2i / ß4is |

α2i / α4is / ß4is |

α4i / ß8is |

|

Servo Motor Model (MITSUBISHI) |

Taper shaft |

HF-75 / 105 |

HF-75 / 105 |

HF-54 / 104 |

|

Speed Reduction Ratio |

– |

1:60 |

1:72 |

1:90 |

|

Max. Rotation Rate of Table (Calculate with Fanuc α Motor) |

r.p.m |

83.3 |

41.6 |

44.4 |

|

Axis (Tilt) |

Tilt (-30º ~ +120º) |

Tilt ±100º |

Tilt ±100º | |

|

Min. Increment |

deg. |

0.001 |

0.001 |

0.001 |

|

Indexing Precision |

sec. |

50 |

50 |

50 |

|

Repeatability |

sec. |

8 |

8 |

8 |

|

Clamping System (Pneumatic) |

kg/cm2 |

6 |

6 |

6 |

|

Clamping Torque |

kg-m |

31 |

31 |

31 |

|

Servo Motor Model (FANUC) |

Taper/Straight shaft |

α4i / ß8is |

α4i / ß8is |

α8i / α12is / ß12is |

|

Servo Motor Model (MITSUBISHI) |

Taper shaft |

HF-54 / 104 |

HF-54 / 104 (Straight shaft is not available) |

HF-104 |

|

Speed Reduction Ratio |

– |

1:90 |

1:120 |

1:90 |

|

Max. Rotation Rate of Table (Calculate with Fanuc α Motor) |

r.p.m |

44.4 |

25 |

44.4 |

|

Allowable Inertia Load Capacity (Horizontal) |

kg.cm.sec2 |

0.97 |

2.2 |

4.13 |

|

Allowable Workpiece Load (0º Horizontal) |

kg |

50 |

60 |

75 |

|

Allowable Workpiece Load (0º~90º Tilt) |

kg |

35 |

40 |

40 |

|

Allowable Load with Rotary Table Clamping (F) |

kgf |

400 |

600 |

750 |

|

Allowable Load with Rotary Table Clamping (FxL) |

kgf.m |

31 |

31 |

31 |

|

Allowable Load with Rotary Table Clamping (FxL) |

kgf.m |

13 |

31 |

31 |

|

Strength of worm gears (Rotary axis) |

kg.m |

9 |

18 |

18 |

|

Net Weight (servo motor excluded) |

kg |

97 |

125 |

160 |