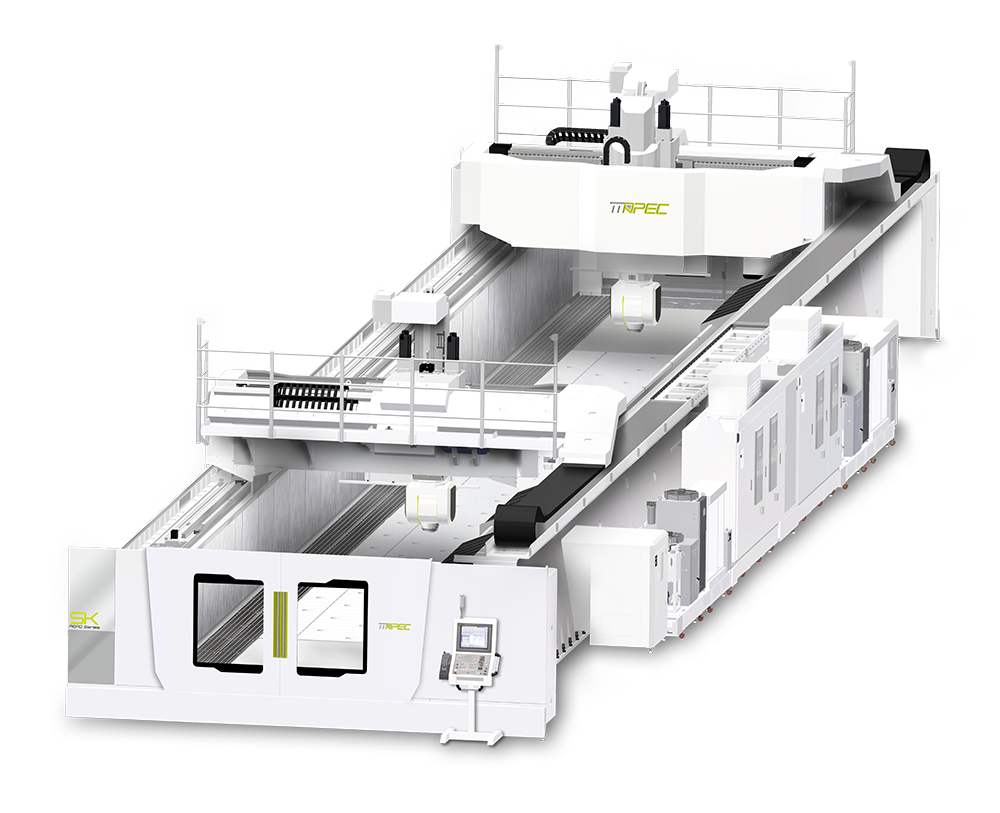

APEC SKM30200-Twin – 5-Axis High Speed Dual Beam Gantry Machining Center

The APEC SKM30200-Twin is an advanced 5-axis double-beam bridge mill engineered for extra-large aerospace structures and ultra-precise high-speed machining. Designed with a dual-crossbeam, twin-spindle configuration, this machining center enables simultaneous dual-part production while maintaining outstanding rigidity, accuracy, and surface quality. Its fully symmetrical box-in-box structure and double-beam gantry deliver superior force-flow balance, ensuring optimal performance during long-travel, high-speed operations.

For aerospace manufacturers, the SKM30200-Twin offers a game-changing solution for machining aluminum alloy structural components such as wing skins, fuselage frames, spars, and bulkheads. Its dual-spindle simultaneous cutting capability drastically reduces cycle times, boosts throughput, and achieves unmatched geometric precision. Combining ultra-high-speed contouring with micron-level accuracy, this series ensures dimensional integrity on thin-wall aluminum parts and other large-scale aerospace components where stability, rigidity, and thermal compensation are critical.

Key Features

Specifications

| Item / Model |

SKM30200-Twin

Request a Quote

|

|---|---|

|

X-Axis |

787.4″ |

|

Y-Axis |

126″ |

|

Z-Axis |

39.37″ |

|

Rapid Traverse |

2,362 IPM |

|

X/Y/Z Axis Acceleration |

16.4 ft./sec2 |

|

Spindle Taper |

HSK-63A |

|

Spindle Speed |

30,000 RPM |

|

Spindle Power (S1/S6) |

134 / 149 HP |

|

Spindle Torque |

44.25 / 56.05 ft./lbs. |