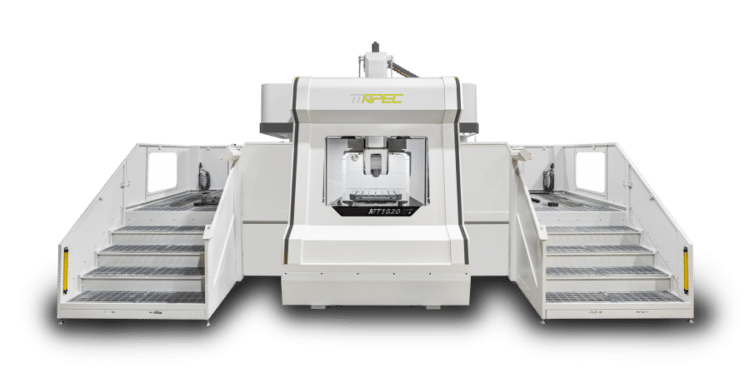

APEC MT20-RT – 5-Axis Bridge-Type Machining Center for Aerospace Engine Casings

The APEC MT20-RT is a specialized 5-axis bridge-type machining center designed specifically for aerospace engine casing manufacturing. Unlike traditional bridge mills, the MT20-RT features a moving table design that shifts the workpiece in and out of the machining envelope, providing optimal accessibility and accuracy when working on large circular and complex engine components.

With its dual-block architecture, arch-shaped column and beam, and high-speed precision ball screw drives, the MT20-RT delivers the rigidity, stability, and precision demanded by leading aerospace OEMs. Competing with solutions from Mazak, Okuma, and Makino, APEC offers a purpose-built alternative for engine casing processing.

Benefits for Metal Cutting Manufacturers

For aerospace manufacturers, the MT20-RT offers a significant productivity and quality advantage. By combining a bridge-type structure with a moving table design, this machine allows precise 5-axis access to all features of large engine casings while maintaining rigidity and stability. Benefits include:

Key Features

Ideal Cutting Applications

Specifications

| Item / Model |

MT20-RT

Request a Quote |

|---|---|

|

X-Axis |

-39.37″ ~ 70.87″ |

|

Y-Axis |

-39.37″ ~ 39.37″ |

|

Z-Axis |

33.46″ |

|

Distance from Spindle End to Table |

-11.81″ ~ 21.65″ (Vertical)2.36″ ~ 35.83″ (Horizontal) |

|

Table Size (LxW) |

49.21″ x 49.21″ |

|

Max Turning |

Ø74.80″ |

|

C-Axis Angle |

±360° (Continuously) |

|

C-Axis Speed |

5 RPM |

|

C-Axis Torque (S1/Max) |

6277.19 / 21434.21 ft. lbs. |

|

Rapid Traverse |

X/Y=65.62’/min |

|

Spindle Taper |

HSK-100A |

|

Spindle Speed |

8-000 RPM |

|

Spindle Power(S1/S6) |

67.11 / 83.66 hp |

|

Spindle Torque (S1/S6) |

234.73 / 294.19 ft. lbs. |

|

Tool Shank |

40T pieces |

|

Max. Tool Length |

15.75″ |

|

Max Tool Diameter with Adjacent Tool |

Ø4.92″ |

|

Max Tool Diameter without Adjacent Tool |

Ø9.84″ |