APEC MTH Series – High Torque Bridge Mills for Titanium & Superalloys

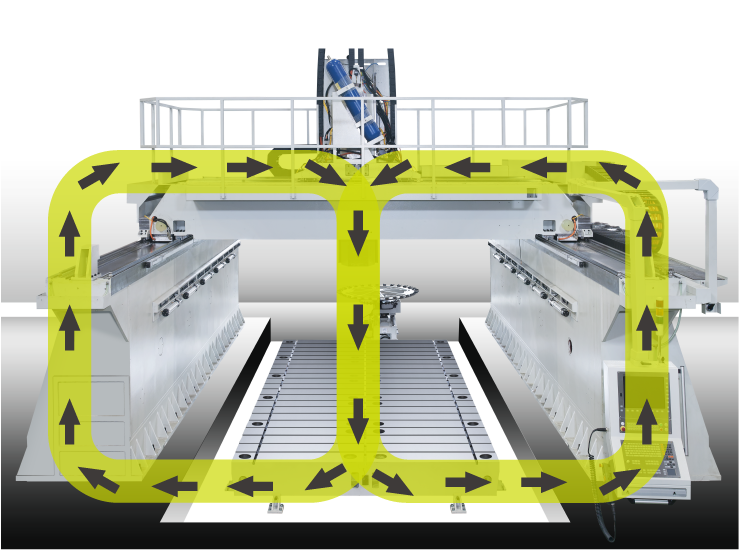

The APEC MTH Series is the heavy-duty evolution of the MT Series, engineered for extreme cutting performance in titanium, Inconel, and high-nickel alloys. Built on the same robust U-shape gantry bridge mill design, the MTH adds reinforced structural stiffness, higher-torque spindles, and heavy-duty drive systems. This makes it ideal for industries such as aerospace, defense, power generation, and energy, where machining strength and reliability are mission-critical. Competing directly with Parpas, Fidia, Zimmerman, Fooke, and FPT, the APEC MTH Series is the clear choice when heavier cuts, deeper material removal, and superior rigidity are required.

Benefits for Metal Cutting Manufacturers

The APEC MTH Series gantry bridge mills give manufacturers the power and stability to handle the toughest materials and heaviest machining conditions, ensuring long-term success in demanding aerospace programs.

By combining rigidity, torque, and precision, the MTH Series provides manufacturers a platform designed to meet the challenges of next-generation aerospace and defense programs.

Key Features

Ideal Cutting Applications

The APEC MTH Series is tailored for heavy-duty aerospace and energy machining where power and rigidity are critical:

Specifications

| Item / Model |

MTH1530

Request a Quote

|

MTH2442 / 62-5S

Request a Quote

|

MTH2842 / 62-5S

Request a Quote

|

|---|---|---|---|

|

X-Axis |

118.11″ |

165.35″ / 244.09″ |

165.35″ / 244.09″ |

|

Y-Axis |

78.74″ |

118.11″ |

137.80″ |

|

Z-Axis |

33.46″ |

39.37″ |

39.37″ |

|

Table Length |

122.05″ |

157.48″ / 236.22″ |

157.48″ / 236.22″ |

|

Table Width |

47.24″ |

81.10″ |

98.43″ |

|

Max Table Load |

10,000 lbs. |

28,000 lbs. |

32,000 lbs. |

|

Rapid Traverse (XYZ) |

98.43 ft. /min |

65.62 ft./min |

65.62 ft./min |

|

Spindle Taper |

HSK-100A |

HSK-100A |

HSK-100A |

|

Spindle Speed |

12,000 RPM |

12,000 RPM |

12,000 RPM |

|

Spindle Power(S1/S6) |

67.10/83.78 HP |

67.05/105.27 HP |

67.05/105.27 HP |

|

Spindle Torque (S1/S6) |

737.56 ft. lbs. |

234.54 ft. lbs. / 368.80 ft. lbs. |

234.54 ft. lbs. / 368.80 ft. lbs. |

|

Recommended 2-Axis Head |

Fork Type Milling Head |

Fork Type Milling Head |

Fork Type Milling Head |

|

Swivel/Rotation Speed |

B=C=30 (cont) /60 (max) RPM | ||

|

Swivel/Rotation Torque |

B=992.58/1,785.16 ft. lbs. C=1,187.12/2,178.61 ft. lbs. |

B=991.30/1,785 ft. lbs. C=1,187.50/2,168.40 ft. lbs. |

B=991.30/1,785 ft. lbs. C=1,187.50/2,168.40 ft. lbs. |

|

Swivel/Rotation Angle |

B = ±120° C = ±360° |

B = ±120° C = ±360° |

B = ±120° C = ±360° |

|

Clamping Torque |

B=4,425 ft. lbs. C=4,425 ft. lbs. |

B=4,425 ft. lbs. C=4,425 ft. lbs. |

B=4,425 ft. lbs. C=4,425 ft. lbs. |

|

Tool Shank |

32T pieces |

32T pieces |

32T pieces |

|

Max Tool Length |

15.75″ |

15.75″ |

15.75″ |

|

Max Tool Diameter with Adjacent Tool |

Ø4.92″ |

Ø4.92″ |

Ø4.92″ |

|

Max Tool Diameter without Adjacent Tool |

Ø9.84″ |

Ø7.87″ |

Ø7.87″ |

|

Weight |

54,000 lbs. |

74,000 lbs. |

94,000 lbs. |

|

Category |

APEC MT Series |

APEC MTH Series |

|---|---|---|

|

Core Function |

High-rigidity 5-axis gantry bridge mill for aerospace and mold & die machining |

Heavy-duty 5-axis gantry bridge mill built for extreme power and heavy cutting |

|

Structural Design |

U-shape gantry structure guides cutting forces directly into base for rigidity |

Same U-shape gantry, but reinforced for higher stiffness under heavy loads |

|

Best For |

Aerospace aluminum, light titanium, and precision mold & die machining |

Aerospace titanium, Inconel, high-nickel alloys, defense and energy applications |

|

Spindle |

High-speed and high-torque spindle options (up to ~20,000 rpm) |

High-torque spindle packages optimized for heavy material removal in hard alloys |

|

Table Design |

Large-format work envelope with chip flushing and high-pressure coolant systems |

Similar large-format envelope, with enhanced chip evacuation and cooling capacity |

|

Automation |

Multi-head exchange options, tool management, integrated probing |

Same options, but reinforced for continuous 24/7 heavy-duty operation |

|

Highlight Advantage |

Balanced performance: rigidity + high accuracy for complex aerospace parts |

Extreme cutting power: maximum torque, stiffness, and reliability in hard alloys |