APEC HS Series — HS-700 & HS-1400 5-Axis Horizontal Machining Centers

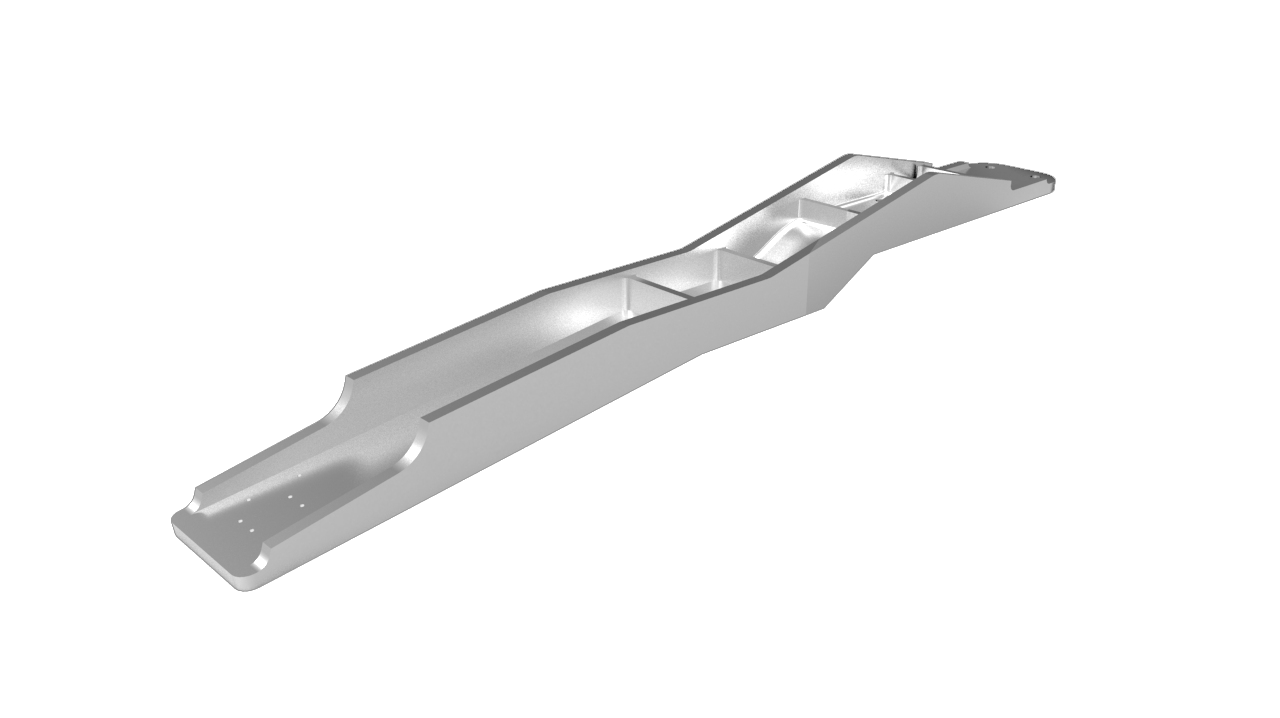

The APEC HS Series 5-axis horizontal machining centers are engineered to handle a wide spectrum of aerospace machining challenges, from high-speed aluminum structures to heavy-duty nickel alloy and titanium components. With reinforced T-structure bases, advanced cooling systems, and high-performance spindles, the HS 700 and HS 1400 deliver stability, accuracy, and flexibility for manufacturers seeking reliable aerospace production solutions.

Benefits of the HS-1400 for Metal Cutting Manufacturers

Key Features of the HS-700

Key Features of the HS-1400

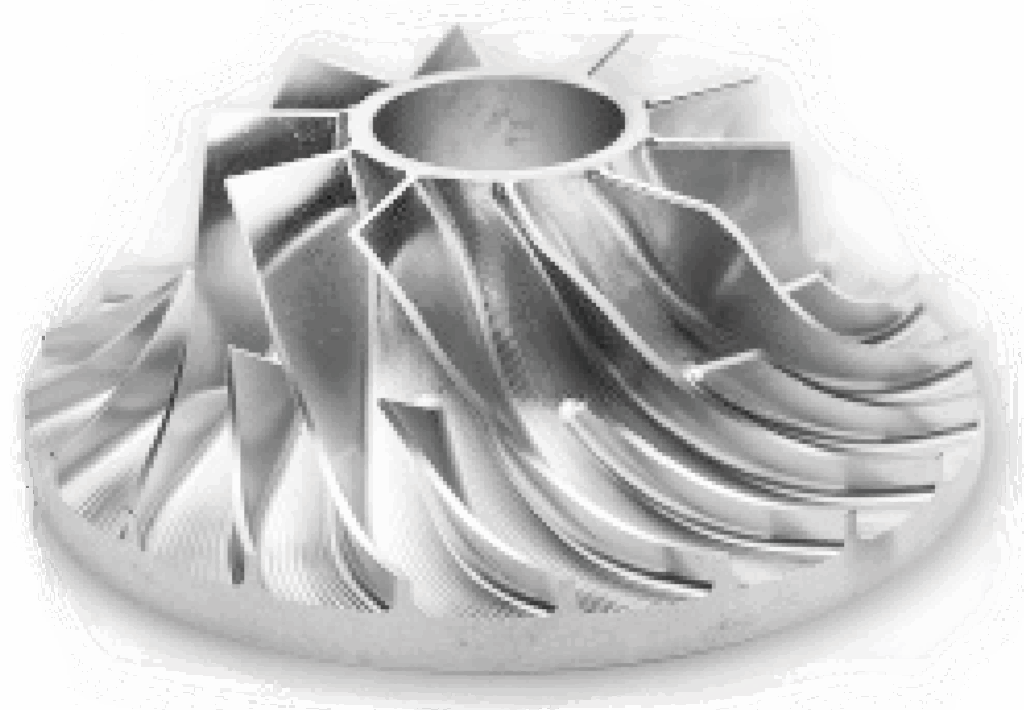

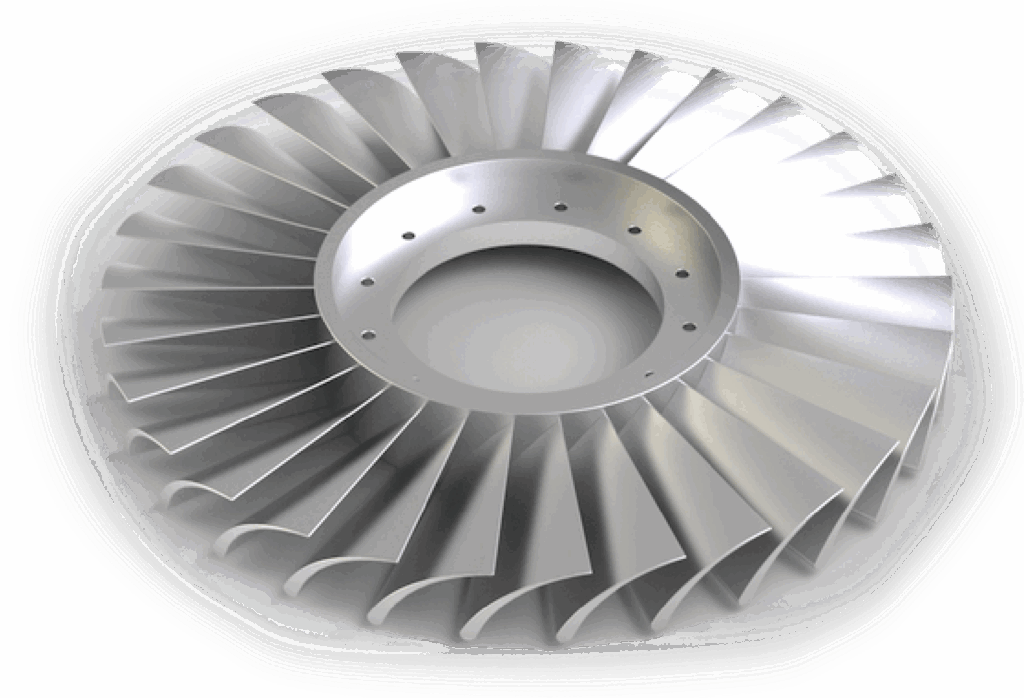

Ideal Cutting Applications for the HS-700

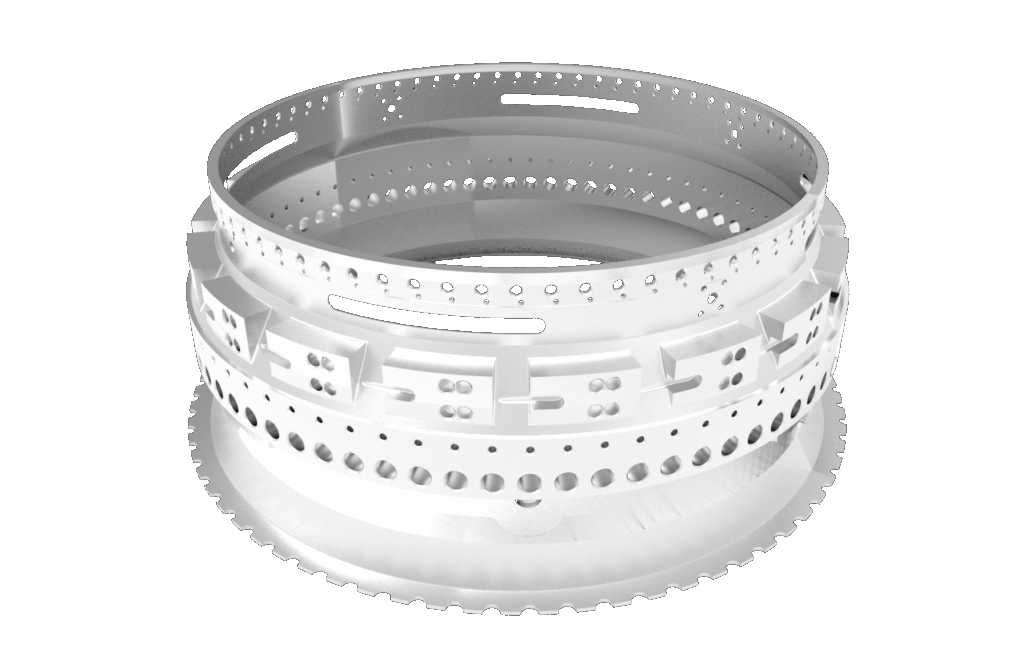

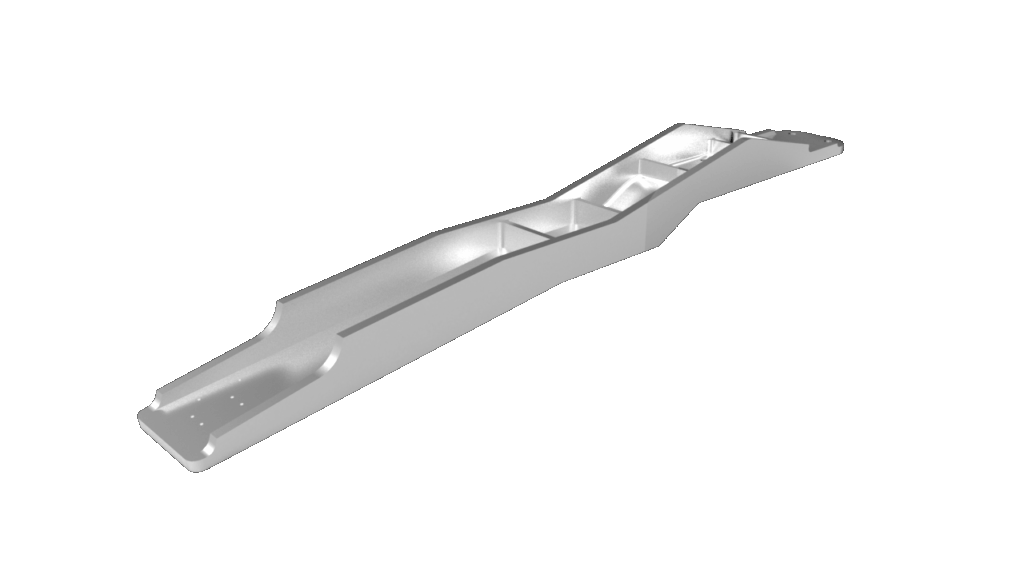

Ideal Cutting Applications for the HS-1400

Specifications

| Specification |

HS700

Request a Quote |

|---|---|

|

X-Axis |

27.95″ |

|

Y-Axis |

35.83″ |

|

Z-Axis |

31.89″ |

|

Feedrate |

XYZ=196.85 ft./min |

|

Table Size ( Diameter ) |

Ø25.59″ |

|

Max Processing Diameter |

Ø27.56″ |

|

Max Table Load |

771.62 lbs. |

|

Max Rotation Angle |

A=-90°~135° C=±360° |

|

Max Rotation Speed |

A=70 C=80 RPM |

|

Torque (S1/Max) |

A=1,574/2,789 ft. lbs. C=495/892 ft. lbs. |

|

Spindle Taper |

HSK-63A |

|

Spindle Speed |

20,000 RPM |

|

Spindle Power (S1/Max) |

26.82/32.18 hp |

|

Spindle Torque (S1/Max) |

33.51/40.56 ft. lbs. |

|

Tool Shank |

32T pieces |

|

Max Tool Length |

15.75″ |

|

Max Tool Diameter with Adjacent Tool |

Ø2.95″ |

|

Max Tool Diameter without Adjacent Tool |

Ø5.12″ |

| Specification |

HS1400

Request a Quote |

|---|---|

|

X-Axis |

70.87″ |

|

Y-Axis |

49.21″ |

|

Z-Axis |

51.97″ |

|

B-Axis Torque (S1/Max) |

84.04/148.13 ft. lbs. |

|

X/Y/Z Axis Acceleration |

XYZ=164.04 ft/min² |

|

Spindle Taper |

HSK100A |

|

Spindle Speed |

12,000 RPM |

|

Spindle Power (S1 / S6) |

67.11/102.40 HP |

|

Spindle Torque (S1 / S6) |

147.51/223.11 ft. lbs. |

|

Tool Shank |

40T pieces |

|

Max Tool Length |

17.72″ |

|

Max Tool Diameter with Adjacent Tool |

4.92″ |

|

Max Tool Diameter without Adjacent Tool |

9.84″ |

|

Weight |

55,115 lbs. |

|

Feature |

HS-700 |

HS-1400 |

|---|---|---|

|

Core Function |

5-axis horizontal machining with inverted machining design for chip flow |

5-axis horizontal machining with single-axis heavy-duty head for torque |

|

Structural Design |

Compact T-structure with inverted dual-V rib base for rigidity and chip evacuation |

Large T-structure with double-wall column and 45° saddle for maximum stability and cutting dynamics |

|

Best For |

High-speed machining of aluminum aerospace structures (wings, spars, ribs, bulkheads, frames) |

Heavy-duty machining of nickel alloys, titanium, superalloys (turbine cases, fuselage frames, landing gear supports) |

|

Spindle |

HSK63A, up to 24,000 rpm, 35–42 kW, up to 67 Nm torque |

HSK100T, 12,000 rpm, 50–76 kW, up to 302 Nm torque |

|

Table Design |

Ø650 mm trunnion rotary table, 350 kg load capacity |

Ø1,250 mm heavy-duty rotary table, 3,200 kg load capacity |

|

Automation |

Multi-Pallet Pool (MPP) up to 18 pallets (600 × 600 mm each) |

Automation-ready, focused on large aerospace part production |

|

Highlight Advantage |

High-speed, automation-ready aluminum part specialist |

Heavy-duty, high-torque superalloy powerhouse |