APEC G-800T & TR Compact 5-Axis Gantry Vertical Machining Centers

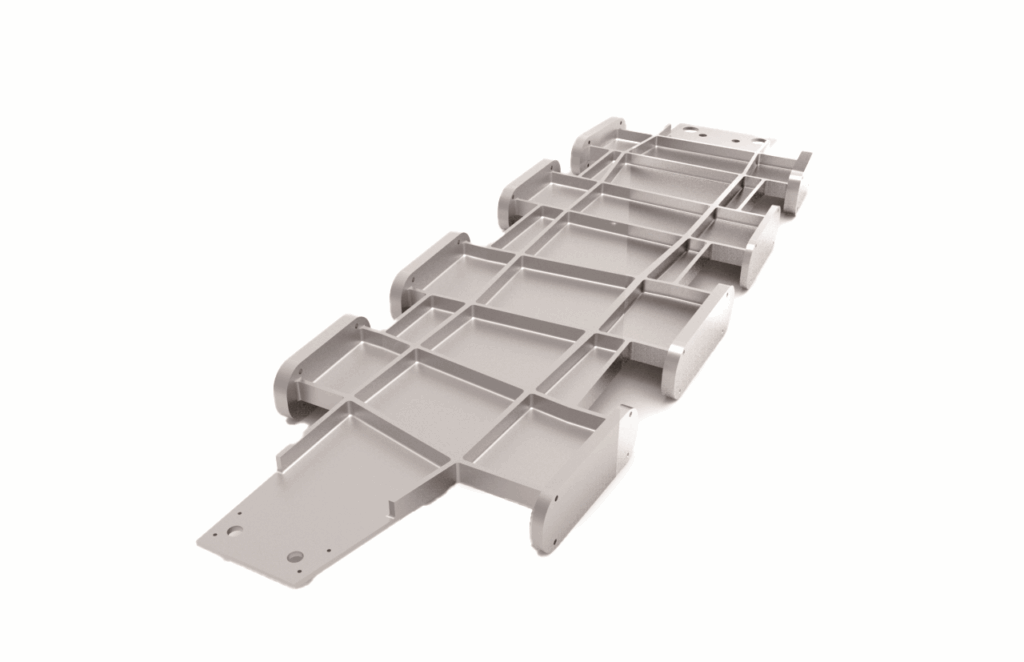

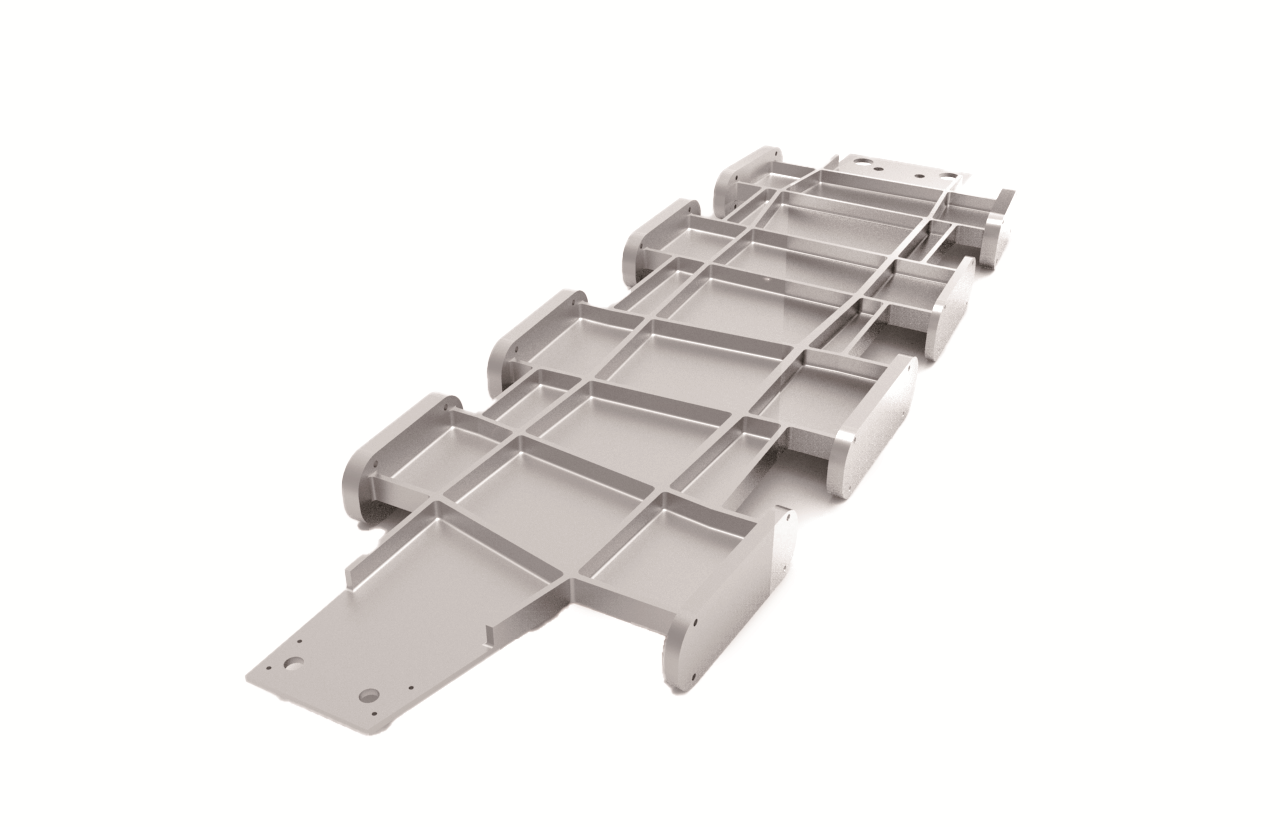

The APEC G-Series, including the G-800T and G-800TR, is engineered for workpieces that demand full 5-axis simultaneous machining across industries such as aerospace, mold and die, and automotive. These compact gantry machining centers deliver high rigidity, accuracy, and efficiency in one streamlined platform. The “T” designation indicates a tilting table for maximum 5-axis machining flexibility, while the “TR” designation adds rotary capability, enabling continuous 5-axis contouring of complex geometries in a single setup.

Compare the G-800T and G-800TR

Benefits of the G-800T for Metal Cutting Manufacturers

Benefits of the G-800TR for Metal Cutting Manufacturers

Key Features of the G-800T

Key Features of the G-800TR

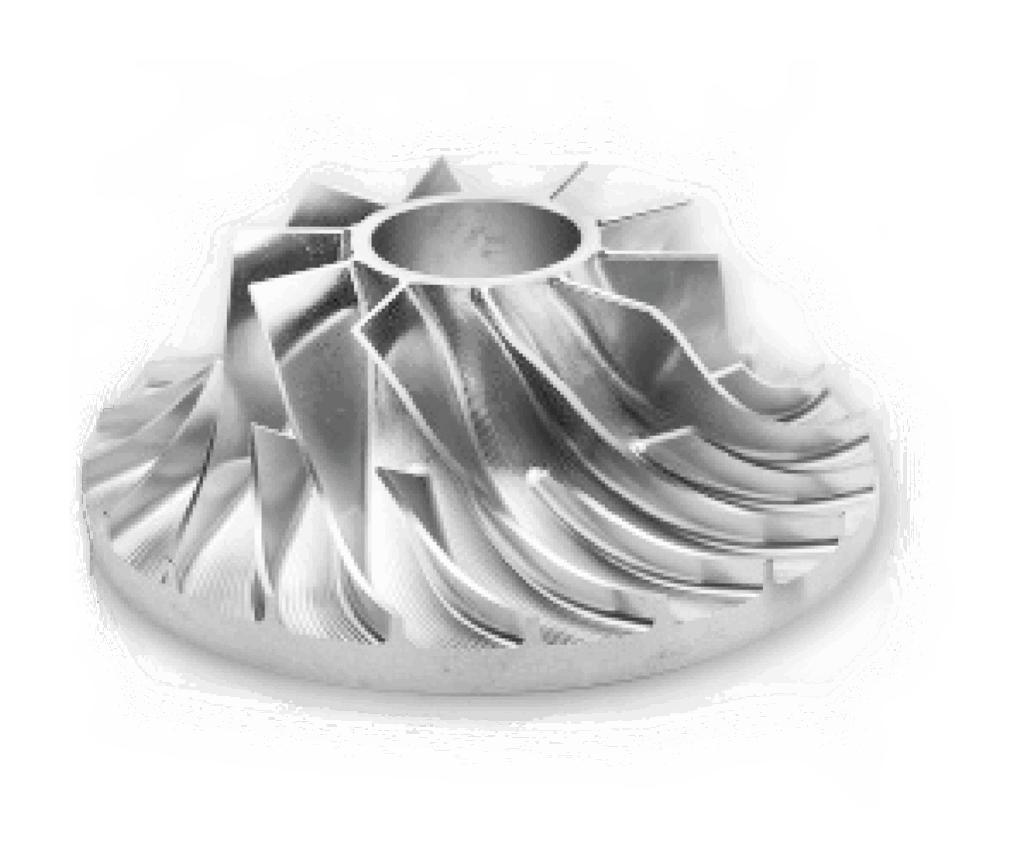

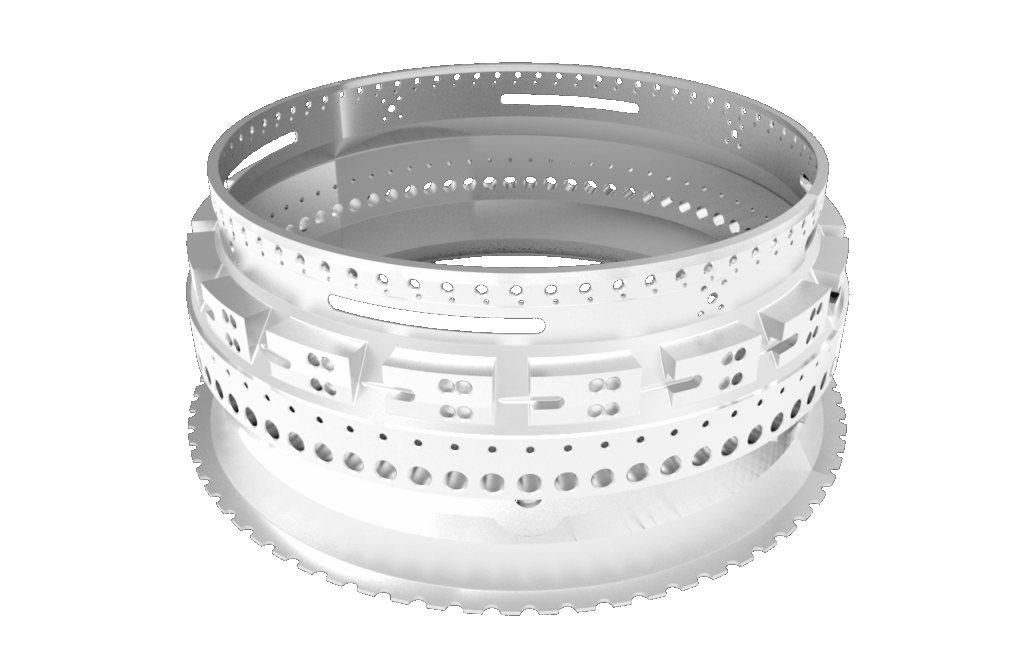

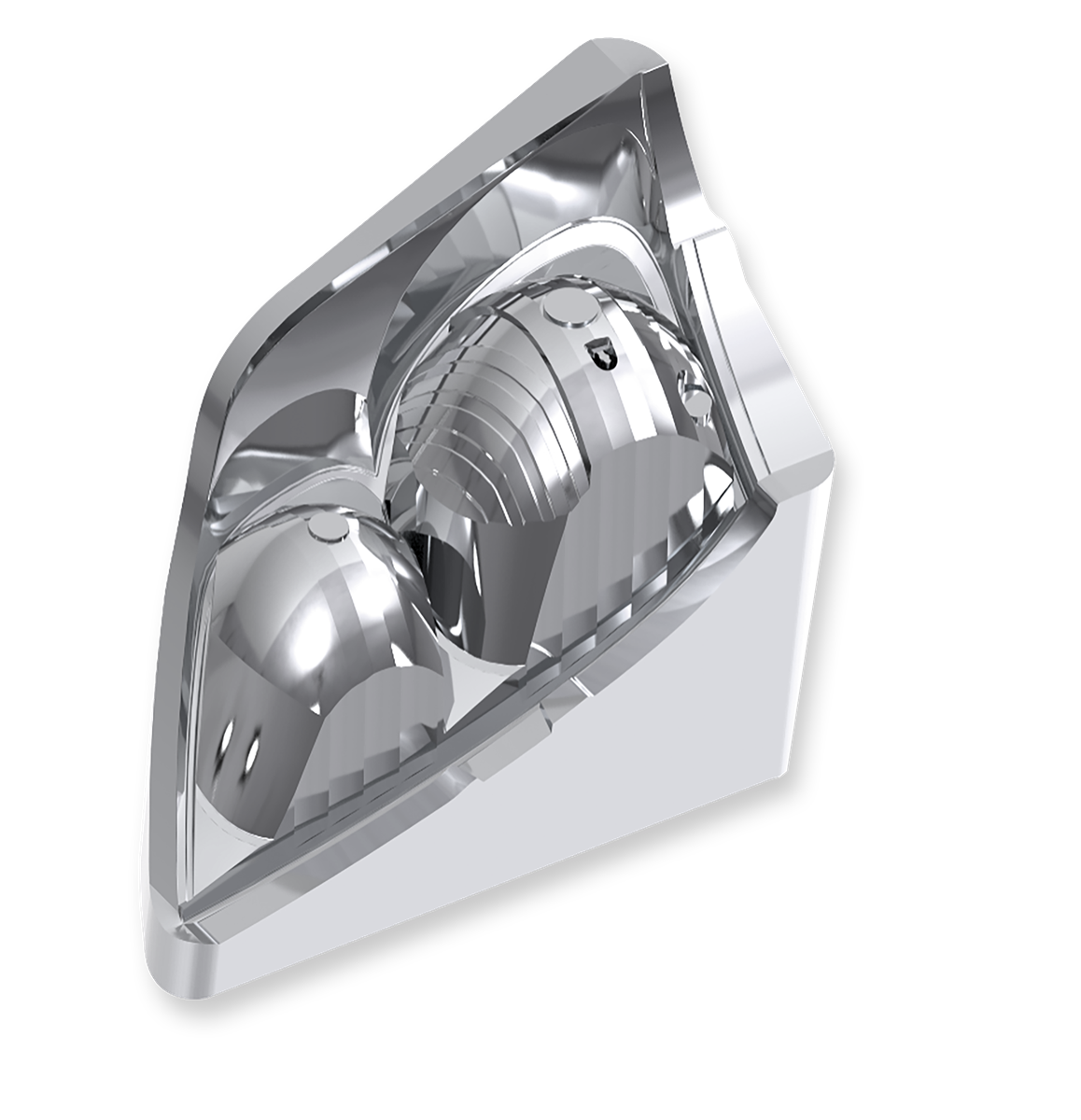

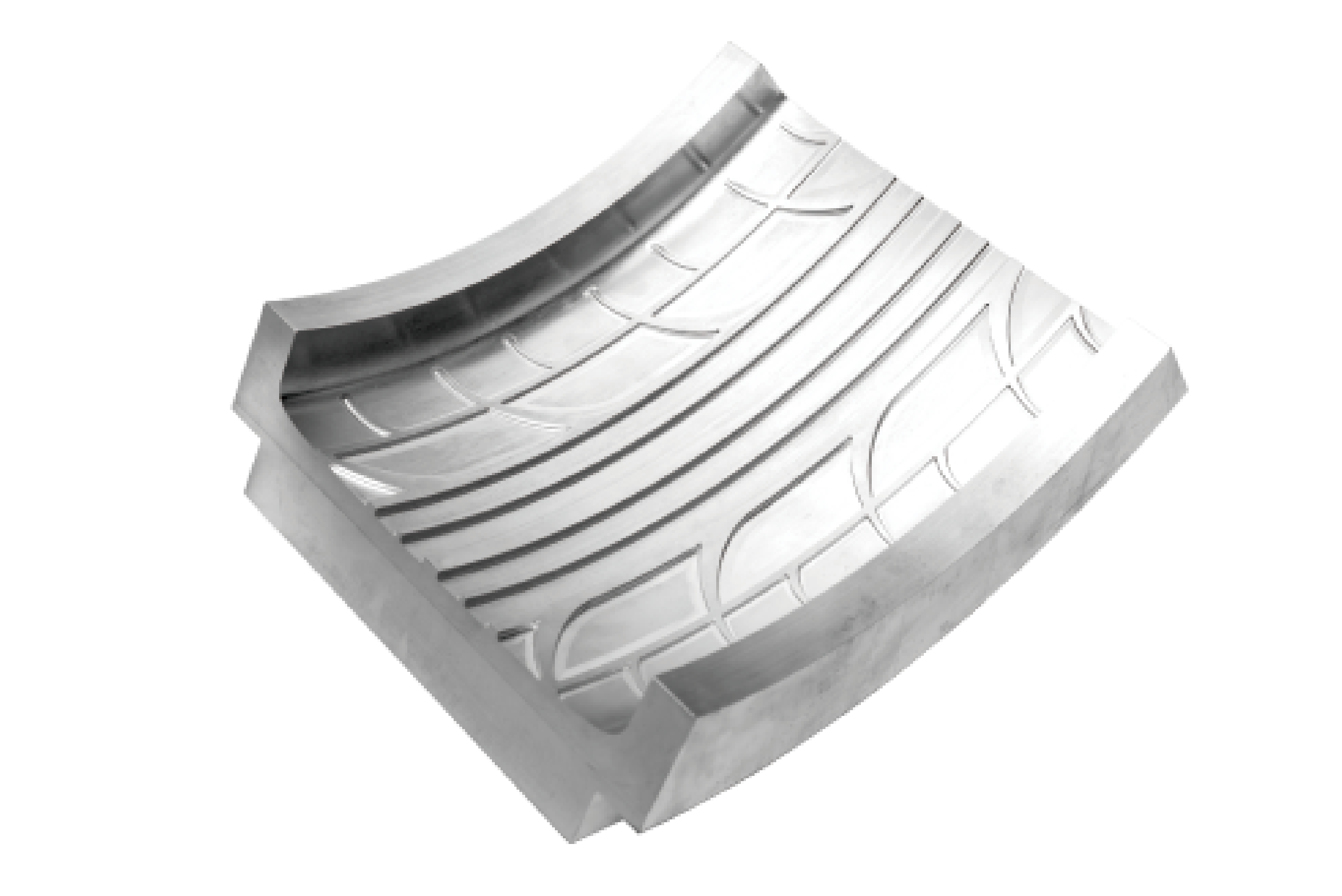

Ideal Cutting Applications for the G-800T

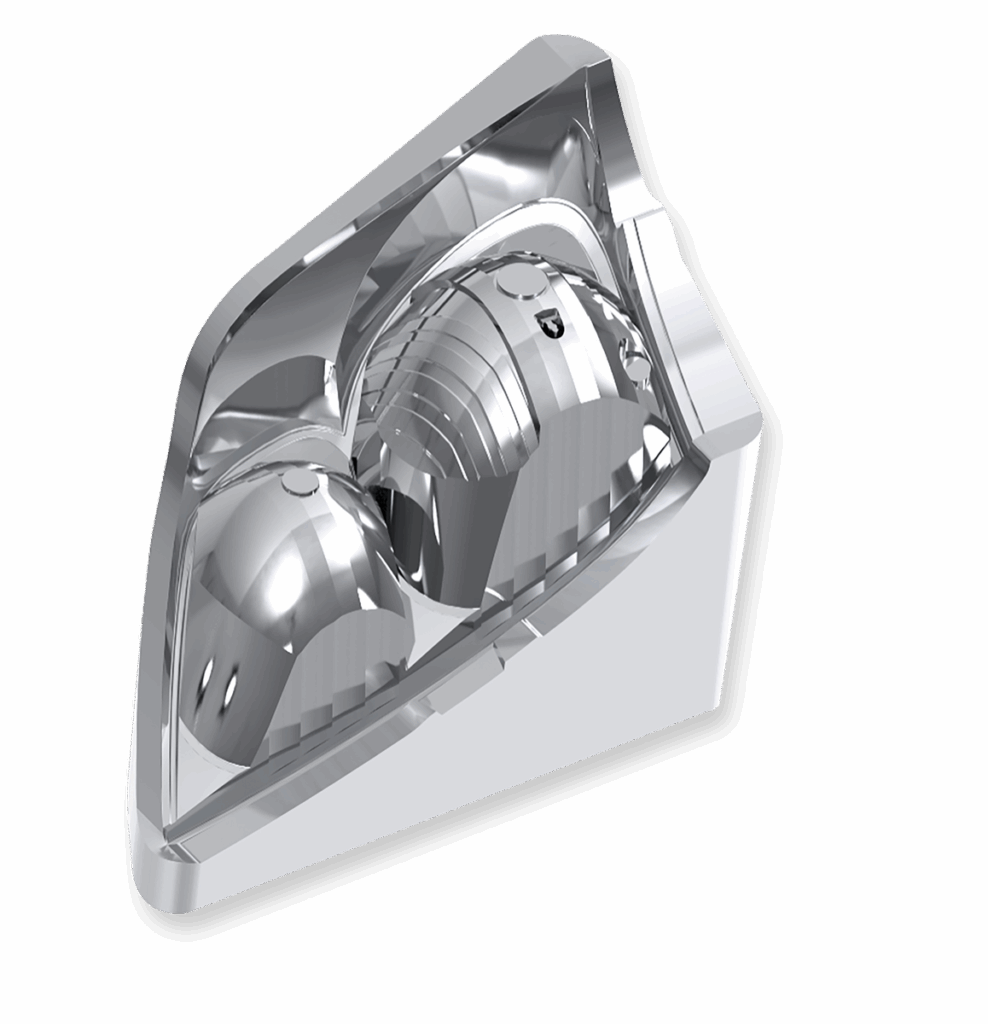

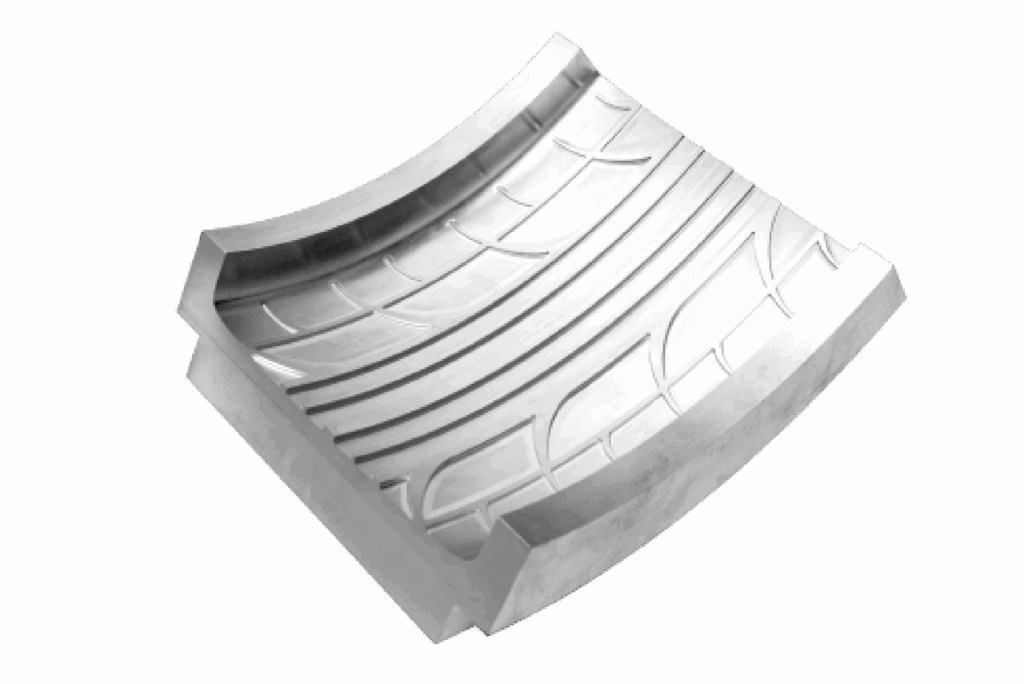

Ideal Cutting Applications for the G-800TR

Specifications

| Item / Model |

G800-TR

Request a Quote

|

G800T

Request a Quote

|

|---|---|---|

|

X-Axis |

31.5″ |

31.5″ |

|

Y-Axis |

32.68″ |

32.68″ |

|

Z-Axis |

22.05″ |

22.05″ |

|

A-Axis |

±120° |

±120° |

|

C-Axis |

±360° |

±360° |

|

A-Axis Torque (S1/Max) |

3,145/5,573 ft. lbs. |

3,129/5,098 ft. lbs. |

|

C-Axis Torque (S1/Max) |

1,574/2,789 ft. lbs. |

1,100/1,815 ft. lbs. |

|

Rapid Traverse |

XYZ=157.48 ft/min |

XYZ=157.48 ft/min |

|

X/Y/Z Axis Acceleration |

13.12 ft/sec² |

13.12 ft/sec² |

|

Spindle Taper |

HSK-63A |

HSK-63T |

|

Spindle Speed |

20,000 RPM |

20,000 RPM |

|

Spindle Power (S1/S6) |

26.82/32.18 HP |

26.82/30.88 HP |

|

Spindle Torque (S1/S6) |

33.51/40.56 ft. lbs. |

62.96/73.06 ft. lbs. |

|

Tool Shank |

32T pieces |

32T pieces |

|

Max Tool Length |

11.81″ |

11.81″ |

|

Max Tool Diameter with Adjacent Tool |

Ø2.95″ |

Ø2.95″ |

|

Max Tool Diameter without Adjacent Tool |

Ø4.72″ |

Ø4.72″ |

|

Weight |

34,174 lbs. |

36,438 lbs. |

|

Features |

G-800T |

G-800TR |

|---|---|---|

|

Core Function |

5-axis machining with integrated turning (C-axis up to 1,000 rpm) |

5-axis machining with dual-supported rotary tilt table for maximum rigidity |

|

Structural Design |

Tilting + rotary table (single-side support, optimized for turning flexibility) |

Dual-supported tilt table structure for higher rigidity, stability, and accuracy |

|

Best For |

Aerospace impellers, blisks, turbine blades, thin-wall titanium parts |

Aerospace structural parts, precision molds, stamping dies, automotive engine cases |

|

Spindle |

HSK63T, 20,000 rpm, up to 123 Nm torque |

HSK63A, 20,000 rpm, up to 55 Nm torque |

|

Drive System |

Tilting + rotary with turning capability |

Tilting + rotary with dual-support for stability |

|

Automation |

Manual setup; best for complex, single-setup parts |

Optional Multi-Pallet Pool (MPP) with up to 18 pallets for unattended machining |

|

Highlight Advantage |

Combines milling + turning in one machine |

Automation-ready for high-volume, long-cycle production |