NEW Accutex ueX10 CNC Controller Designed with a “User Experience” Focus

The latest in CNC controls for wire EDM machining has arrived. Introducing the NEW ueX10 CNC control from Accutex EDM. Wire EDM machine manufacturers are continually researching to develop improved machine features and capabilities. Accutex EDM is no different, but this time the focus changed to not only improving features and capabilities, but more importantly the “user’s experience” as it relates to the EDM machine’s CNC controller.

AccuteX EDM presented this concept to Mark Cicchetti, EDM Technical Director at Absolute Machine Tools, and the project was launched. The new ueX10 CNC control is the result of a five-year development project between Accutex EDM in Taiwan and Absolute Machine Tools. Its “user’s experience” offers easy integration and technological advancements using a 21” touch screen with Windows 10 operating system.

Improved productivity features were also integrated in the redesign of the ueX10 CNC controller such as:

Full support from Windows 10 OS allows for easier and more manageable future software updates, built-in cloud-based applications, simple automation integration, and more advanced network monitoring capabilities.

Mark Cicchetti, EDM Technical Director at Absolute Machine Tools, said, “The new standard ueX10 CNC control proves that Accutex EDM is committed to creating smart factory advancements that allow manufacturers the latest and greatest in technology while also giving both large and small manufacturers the same production opportunities.”

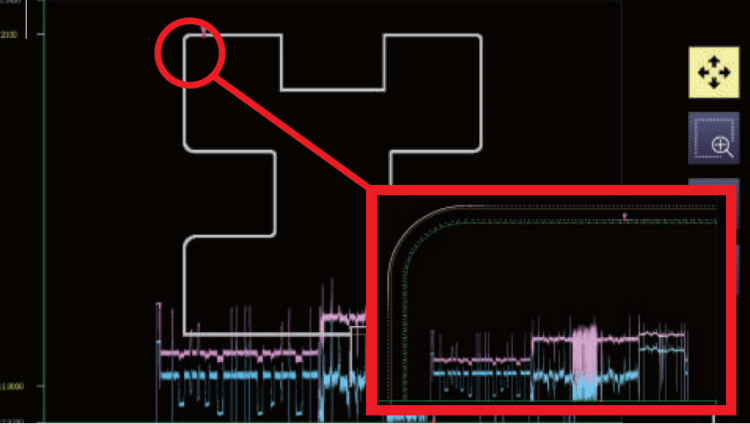

Motor Torque Monitoring System

The Motor Torque Monitoring System, which is a 100% automatic torque measuring function, ensures smooth interference-free motion over the full stroke of the machine.

Processing History Library

Processing and recording information such as speed, gap voltage and other machining details is critical to the overall performance especially for corner and arc processing. The user can later review these details to confirm final cutting results.

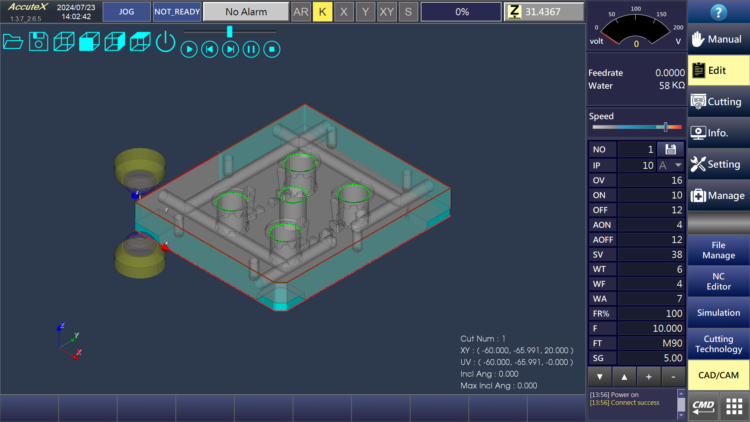

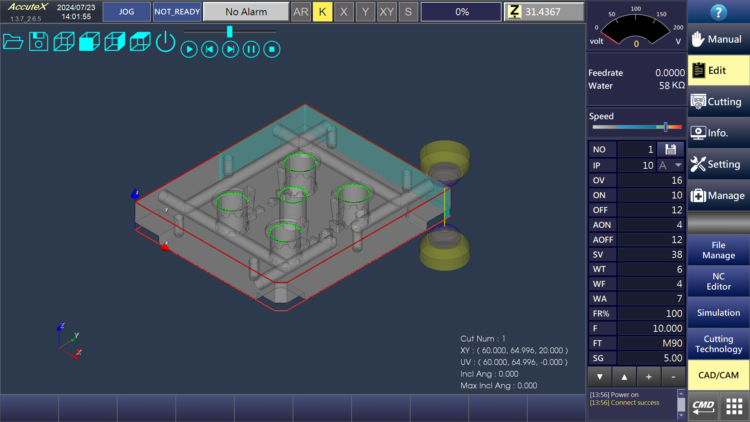

Faster Simulation Performance

Ultra-fast simulation with 2D or 3D rendering of large NC programs allows the operator to efficiently and thoroughly inspect program paths verifying accurate toolpaths from post processing.

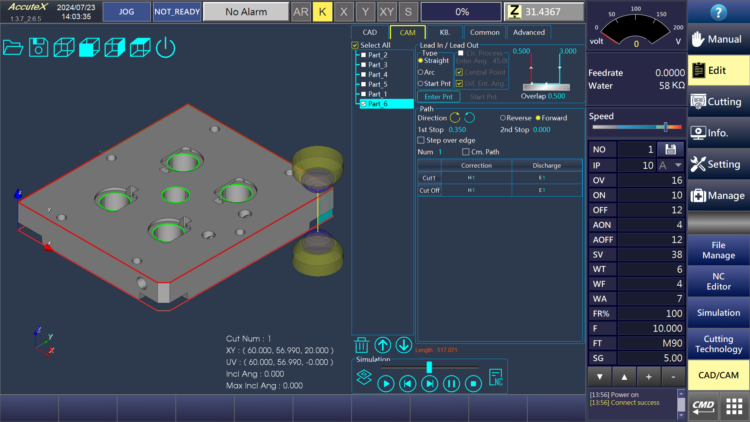

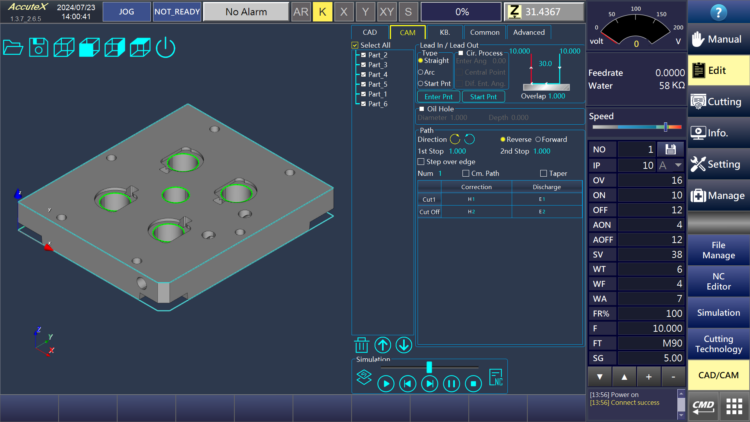

Delta CAD/CAM Onboard

Built-in Delta CAD/CAM is standard on the ueX10. With quick user-friendly geometry creations, operators can go from print to program in minutes. Full network and cloud capable CAD files can be uploaded with toolpaths created for total efficiency and flexibility at the shop floor level.

Automatic Alignment Templates

This capability allows users to preconfigure calibration and part alignment operations that can be saved and selected for future redundant tasks. Using these proven templates increases productivity and dramatically reduces operator error across operators and shifts.

EtherCAT

Integration of EtherCAT levels-up ueX10’s user experience! EtherCat is a fieldbus which meets the needs of standard high performance industrial communication protocols based on an Ethernet network. Another way to describe EtherCAT is that it is the latest and greatest way to control machine tool drive motion. EtherCAT offers exceptional performance, flexibility through multiple connections to servo drives, integrated safety features for network arcature, simple and robust integration, and reduces the cost of hardware and repair. Another attribute is the use of the Linux OS to drive the EtherCAT. The Linux kernel is a widely ported operating system kernel, available for devices ranging from mobile phones to supercomputers, and is the perfect choice for stable high-speed use in industrial applications.

NexGen Automatic Wire Threader (AWT)

Accutex’s latest AWT makes an already 97% reliable system even better and easier to maintain. It expands conversational cutting condition selection and imbedding, full automation integration and monitoring, automatic core removal module for 100% unattended production, and LINE messenger to fully monitor machine operations from your cell phone or other mobile device.