Accutex AU-9i Moving Table Flushing-Type Wire EDM

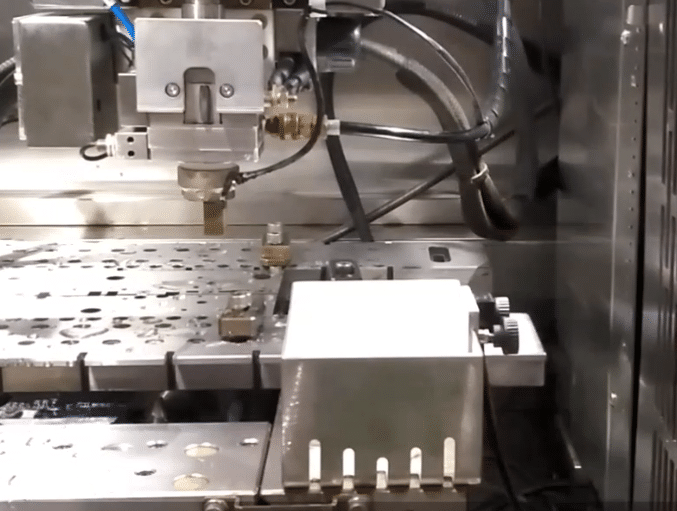

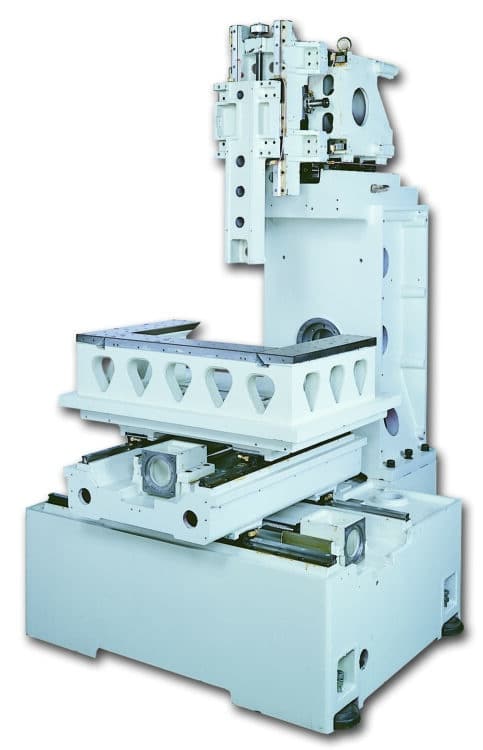

The Accutex AU-9i Series is a high-precision flushing-type CNC wire EDM system engineered for demanding mold & die, aerospace, medical, and precision component manufacturing. The AU-9i features a moving table in both X-axis and Y-axis. It boasts an open-construction design with a flushing-type system built to accommodate oversized workpieces that exceed the capacity of even the largest standard tanks, offering maximum flexibility and accessibility. Designed using Finite Element Analysis (FEA) for maximum rigidity, the AU-9i Series ensures sub-micron accuracy, superior surface finishes, and long-term reliability. Competing head-to-head with Mitsubishi, Sodick, Makino, Fanuc, and GF AgieCharmilles, the AU-9i delivers best-in-class precision and performance at a significantly lower total cost of ownership.

Key Features

- Finite Element Analysis (FEA)-optimized structure with Meehanite honeycomb base and reinforced lower arm for maximum stiffness

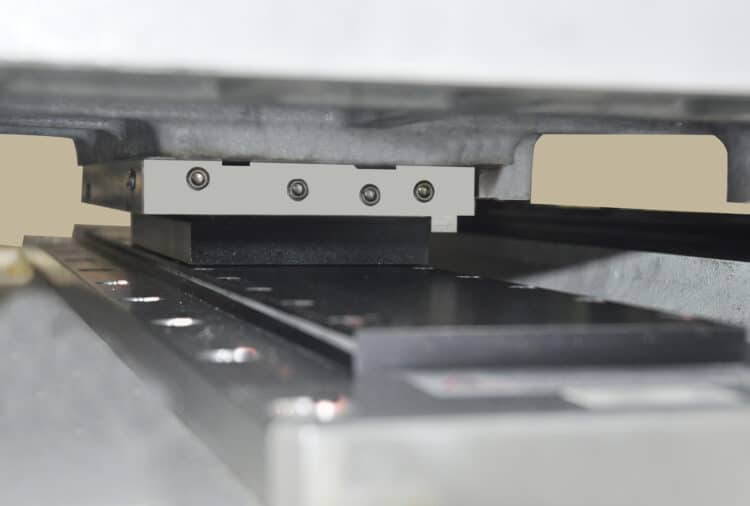

- C1-class ball screws (1.26″ dia.) with sub-zero finish grinding for minimal pitch error and superior smoothness

- Hiwin linear guideways with patented low-friction design reducing vibration up to 90%

- Fully closed-loop feedback system with Fagor linear glass scales (0.000004″ resolution)

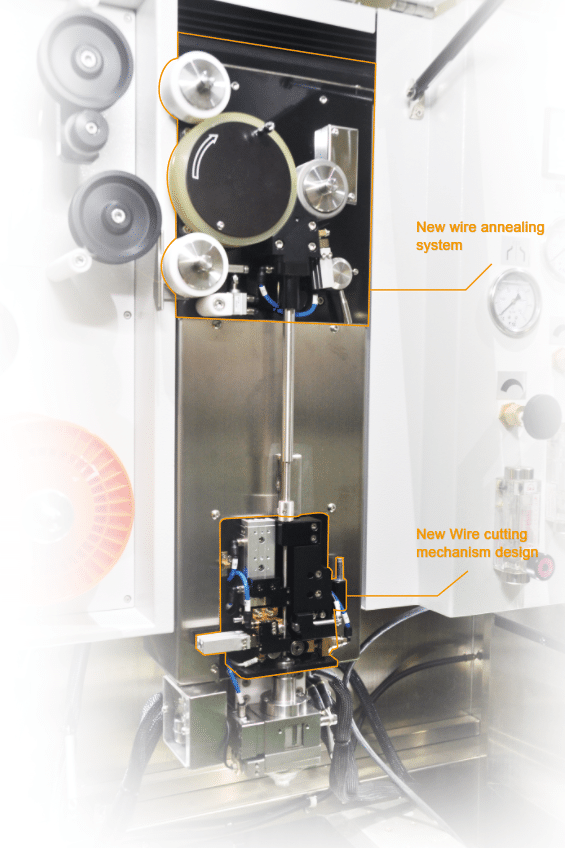

- Automatic Wire Threading (AWT) – intelligent servo control rethreads at break point for the fastest, most reliable wire threading in the industry

- 64-bit Windows CE-based CNC control with 15″ color touch screen and conversational programming

- SD Master anti-electrolysis circuit for enhanced surface integrity and longer electrode life

- ±45° taper cutting capability (with wide-angle guides)

- Hardened stainless-steel worktable compatible with commercial clamping systems

- Integrated dielectric chiller system (1.5-ton capacity) with automatic conductivity and temperature control

- Optional rotary table, wire chopper, and Marposs T25G part probe for expanded automation and in-process measurement

Specifications

| Item / Model |

AU-9i

Request a Quote

|

|---|---|

|

X Axis Travel |

35.43″ |

|

Y Axis Travel |

23.6″ |

|

Z Axis Travel |

11.8″ |

|

U Axis Travel |

3.9″ |

|

V Axis Travel |

3.9″ |

|

Table Feed Rate |

40.0 IPM |

|

Max. Taper Angle |

±45° |

|

Max. Workpiece (XYZ) |

54.2″ x 29.9″ x 11.6″ |

|

Max Workpiece Weight |

4,890 lbs. |

|

Wire Diameter |

0.006″ – 0.013″ |

|

Wire Spool Feed Rate |

60 – 787 IPM |

|

Wire Tension |

300 – 2,200 grams |

|

Start Hole Diameter |

0.020″ ∅ |

|

Max. Wire Spool Weight |

35 lbs. |

|

Positioning Accuracy |

±0.00012″ |

|

Repeatability (XY) |

±0.00008″ |

|

Total Power Required |

15 KVA |

|

Deionized Resin Tank |

935 0.4 cu/ft Fiberglass Bottle |

|

Tank Capacity |

100 Gallons |

|

Floor Space |

128″ x 126″ x 90″ |

|

CNC Control Screen |

15″ Color Touch |

|

CNC Control Device |

64-Bit Windows Based CE PC |

|

Weight |

11,880 lbs. |