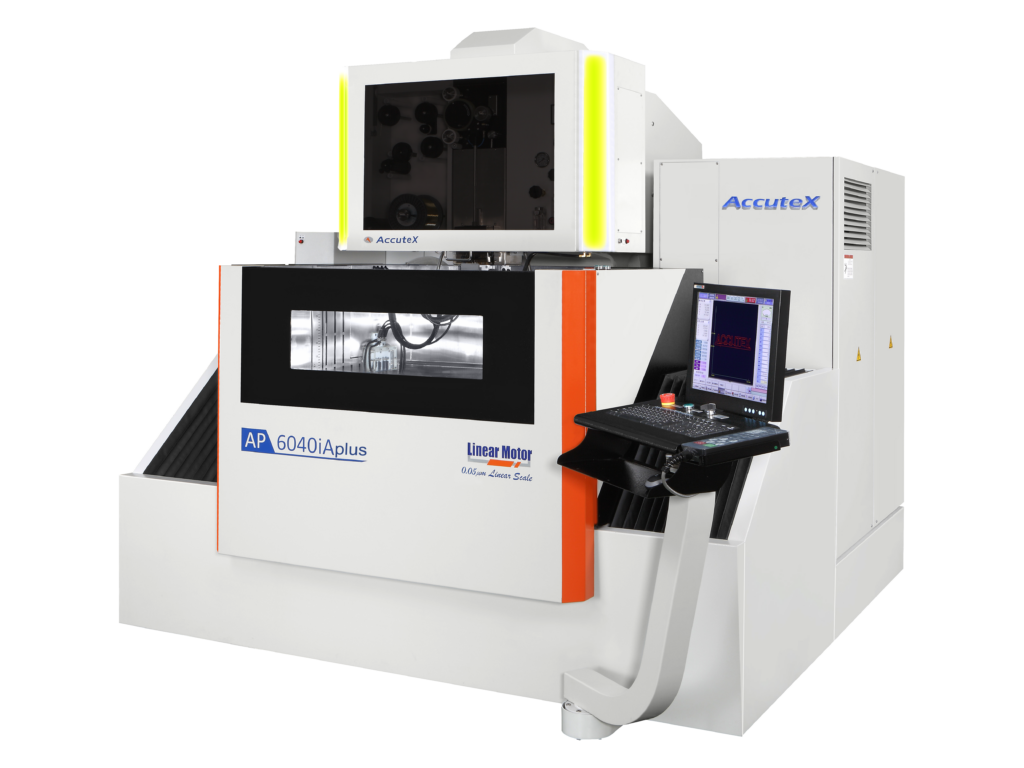

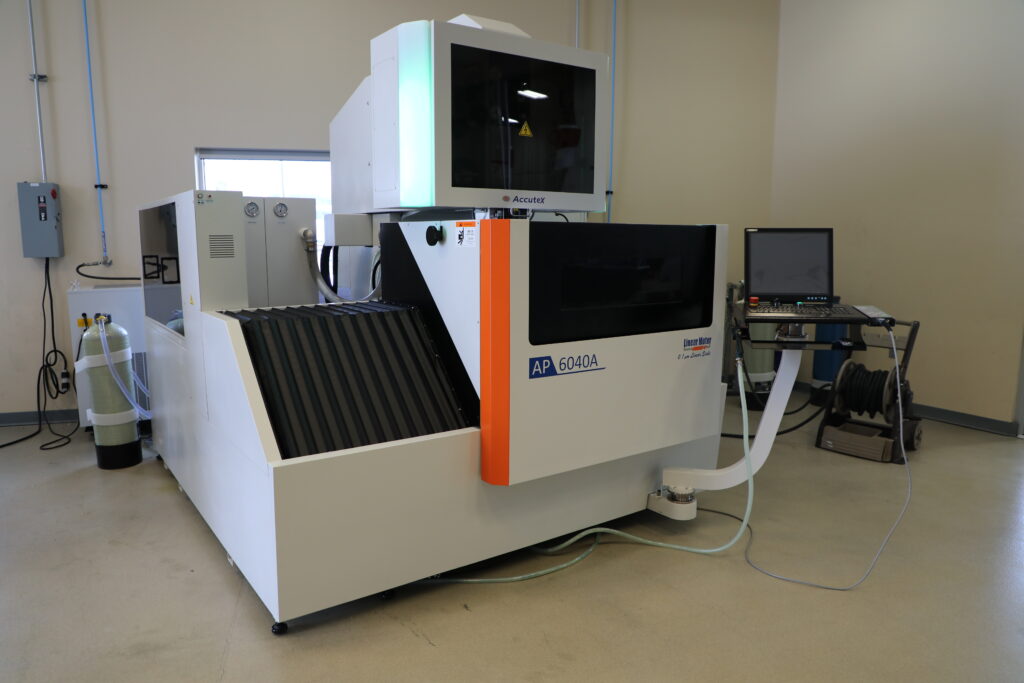

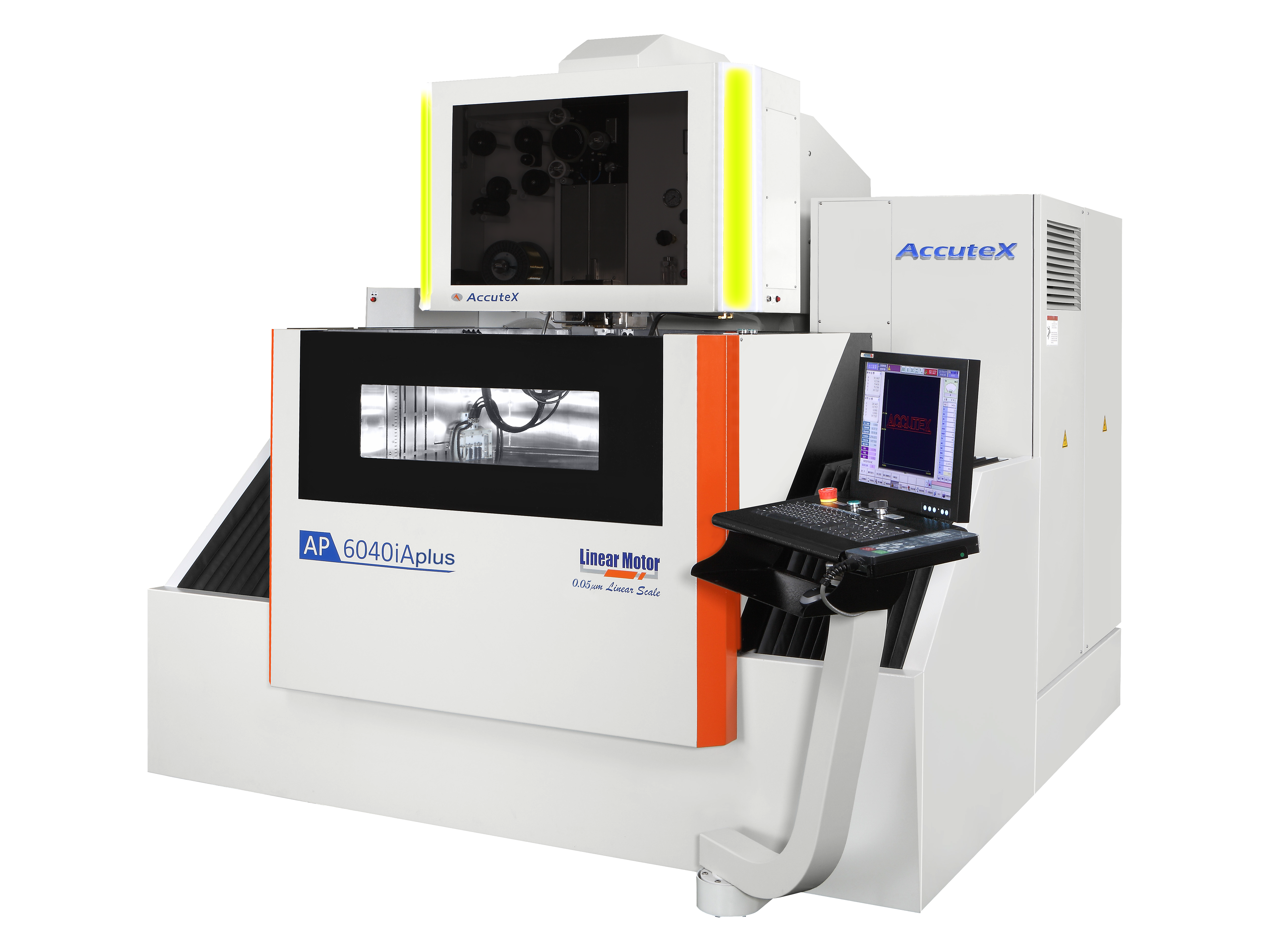

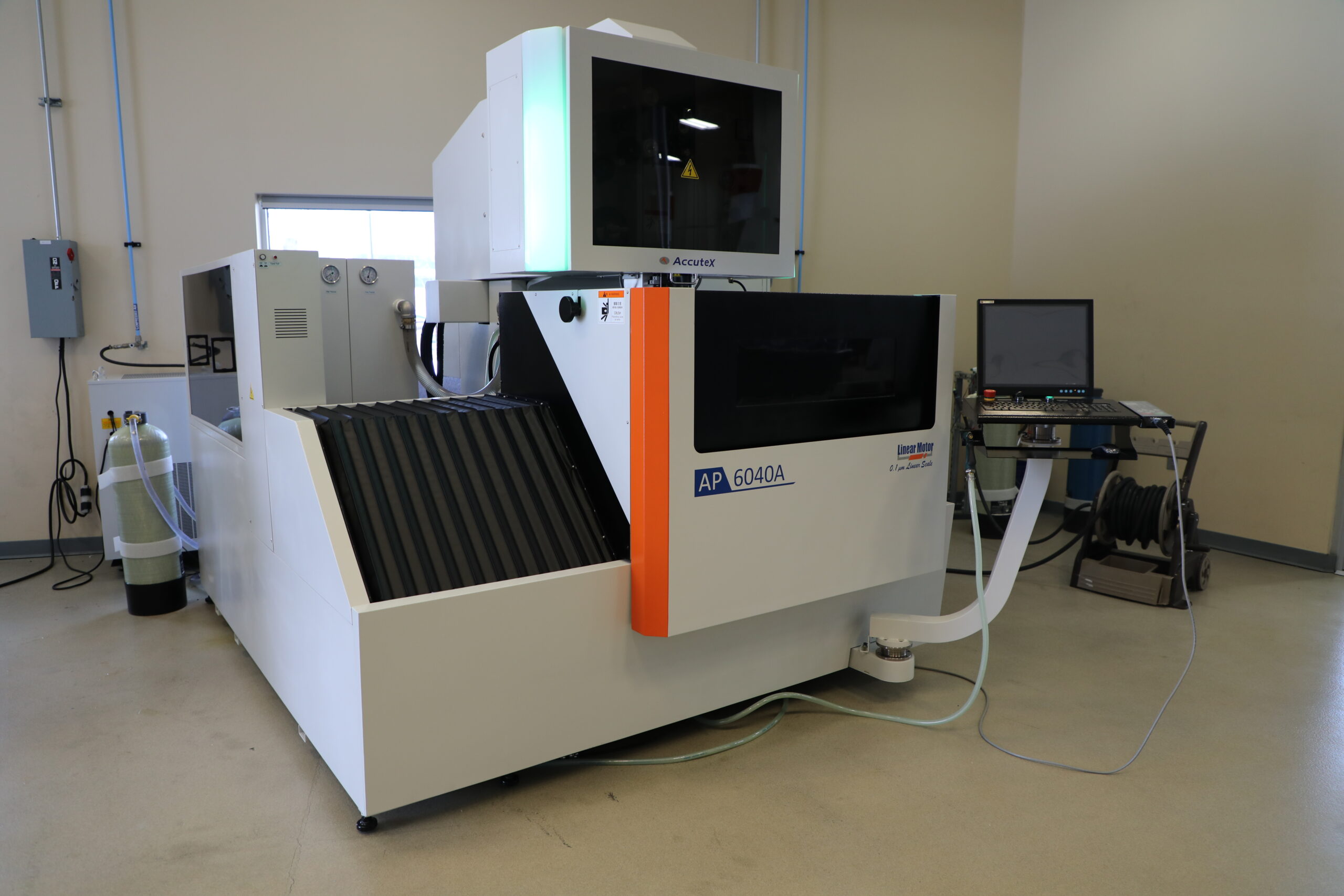

Accutex AP Series – Hybrid X-Axis Moving Table, Y-Axis Moving Column Submerged Type Linear Motor Wire EDM

The Accutex EDM AP Series is a submerged-type linear motor wire EDM constructed with a hybrid table design — a moving X-axis table and Y-axis moving column — that keeps the center of gravity perfectly balanced between dual X-axis linear guideways. This configuration ensures exceptional rigidity, stability, and geometric accuracy while preventing accumulated stack errors between axes. The design is optimized by Finite Element Analysis (FEA) to minimize deformation and deliver long-term precision.

The AP Series supports a maximum workpiece load of 2,425 lbs (1,100 kg) and achieves bi-directional repeatability within ±2.5 µm, setting a new benchmark for precision. Powered by Accutex’s in-house linear motor drive system, the AP Series combines sub-micron accuracy, ultra-fine surface finishes, and superior productivity for aerospace, medical, and mold manufacturing applications — rivaling Mitsubishi, Makino, GF AgieCharmilles, Sodick, and Fanuc.

Key Features

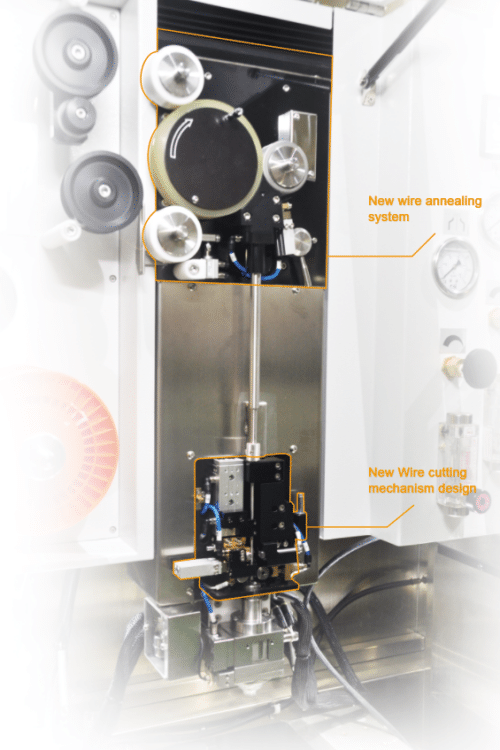

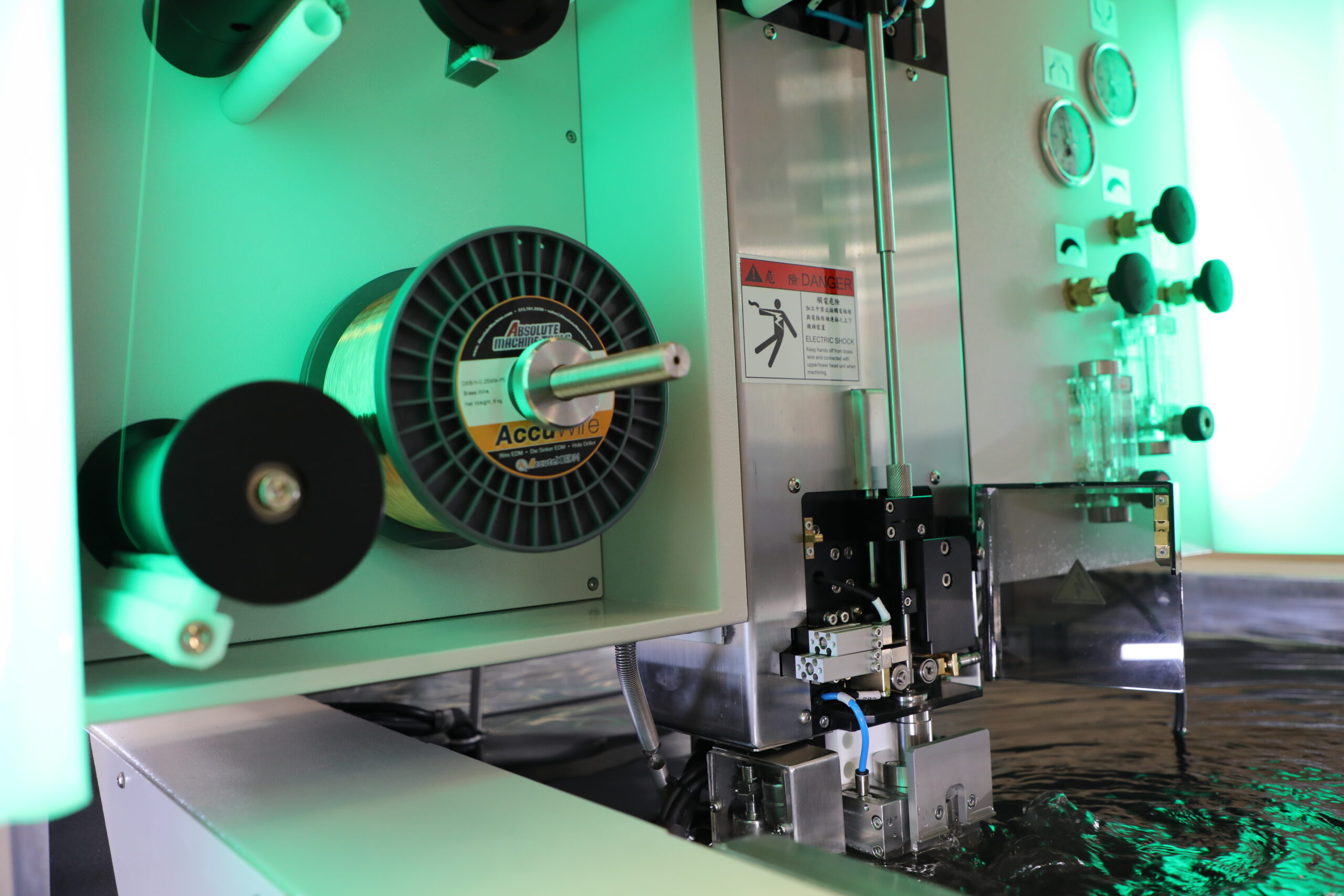

- Linear Motor Drive System (X, Y) – In-house Accutex linear shaft motors provide zero backlash, high-speed response, and maintenance-free performance.

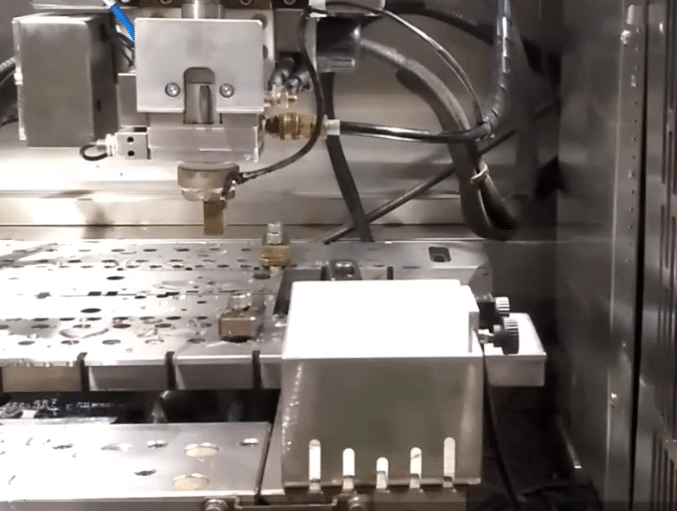

- Hybrid Table Design (X-Axis Table / Y-Axis Column) – Balanced structure keeps the machine’s center of gravity aligned between dual guideways and minimizes deflection under heavy cutting conditions.

- 64-bit Windows 10–based ueX10 CNC Control – Developed in partnership with Absolute Machine Tools, this advanced interface integrates simulation, torque monitoring, and cloud connectivity.

- EtherCAT Motion Control – Ensures ultra-fast, stable communication for synchronized, interference-free axis motion.

- Built-In Delta CAD/CAM System – Allows quick geometry creation, toolpath generation, and file transfer directly from the control.

- Automatic Alignment Templates – Preconfigured routines simplify calibration and setup while reducing operator error across multiple shifts.

- SD Master Stable Discharge Circuit – Maintains consistent spark energy and high surface quality for reliable fine-finishing operations.

- High-Resolution Fagor Linear Glass Scales (0.000004″) – Closed-loop feedback enables sub-micron positional accuracy and repeatability.

- ±30° Taper Cutting Capability – Precision cutting for complex profiles, molds, and aerospace tooling applications.

- Automation Ready – Fully compatible with robotic loaders, pallet changers, and A+ Automation solutions for lights-out EDM production.

Specifications

| Item / Model |

AP-4030A

Request a Quote

|

AP-6040A

Request a Quote

|

|---|---|---|

|

Max. Workpiece Size L x W x H |

31.49″ x 22.05″ x 10.5″ |

41.33″ x 30.51″ x 13.58″ |

|

Max. Workpiece Weight |

2,200 lbs. |

2,450 lbs. |

|

X/Y Stroke |

15.74″ x 11.81″ |

22.62″ x 15.74″ |

|

UV Stroke |

6.30″ |

6.30″ |

|

Z Stroke |

10.60″ |

13.78″ |

|

Max. Cutting Taper |

±45° |

±32° |

|

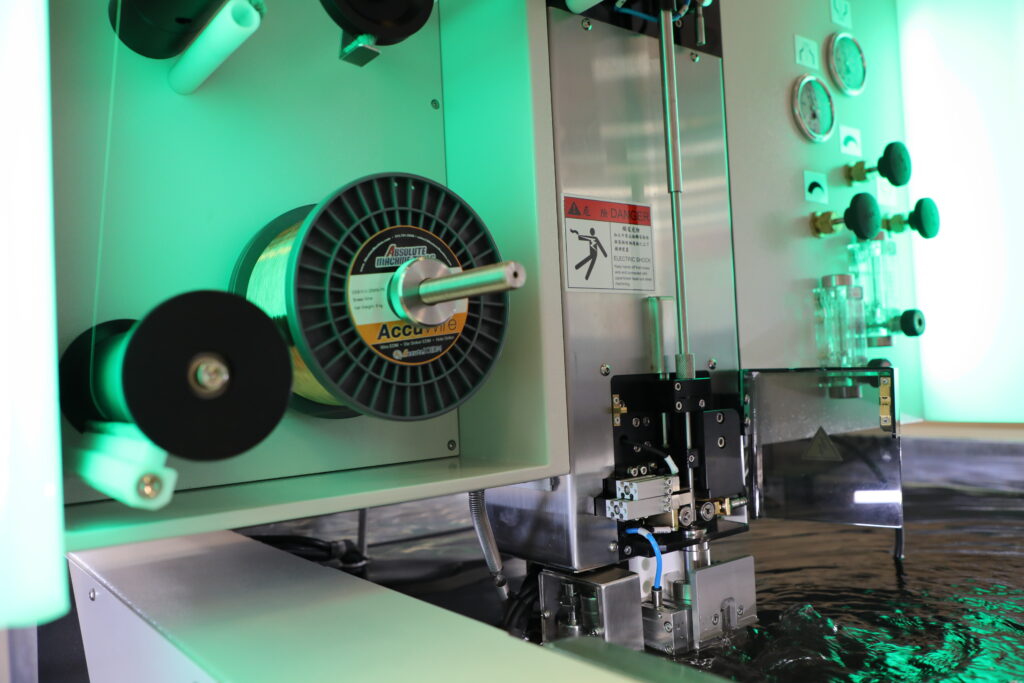

Max. Wire Spool Weight |

35 lbs. |

35 lbs. |

|

Foot Print WxDxH |

84″ x 108″ x 88″ |

91″ x 110″ x 93″ |

|

Water System Capacity |

264 Gallons |

264 Gallons |

|

Machine Weight |

8800 lbs. |

8800 lbs. |