Core CNC Solutions for Aerospace

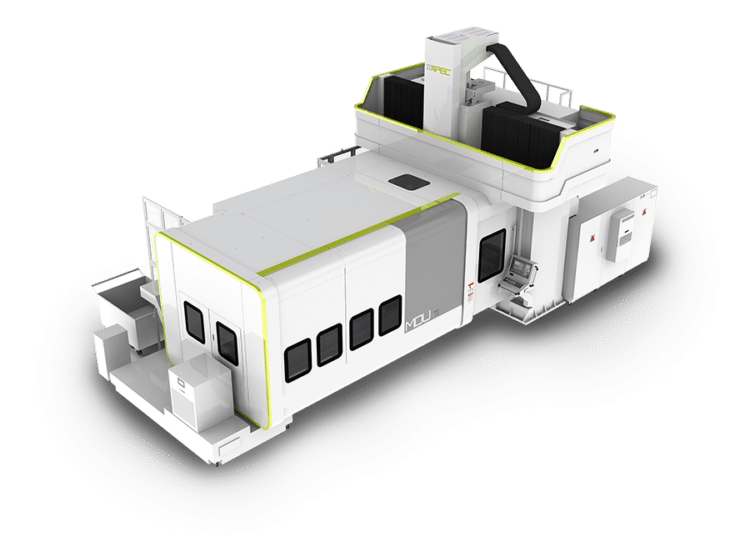

5-Axis & Extra-Large Format Machining (APEC)

Vertical Turning Lathes (You Ji)

Bridge Mills for Aerospace Tooling (Johnford)

Deep Hole Drilling & EDM Solutions

Moving Table and Sliding Column designs. These machines can be Customized to fit any application and can sometimes take up less floor space than equivalent C-frame verticals

Moving Table and Sliding Column designs. These machines can be Customized to fit any application and can sometimes take up less floor space than equivalent C-frame verticals

Ideal Aerospace Applications

Why Absolute for Aerospace?

For decades, Absolute Machine Tools has partnered with aerospace OEMs and tier suppliers to provide cost-effective, engineered CNC solutions. Our portfolio combines global-leading machine tool technology with the local applications expertise and support needed to meet the industry’s uncompromising standards. Contact us today to learn more.