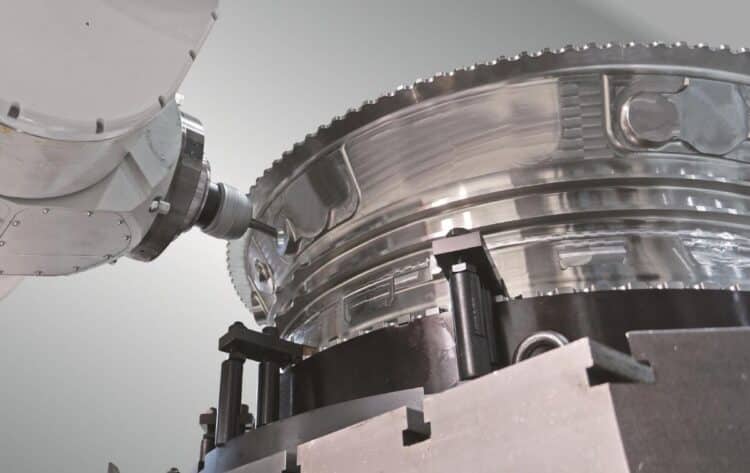

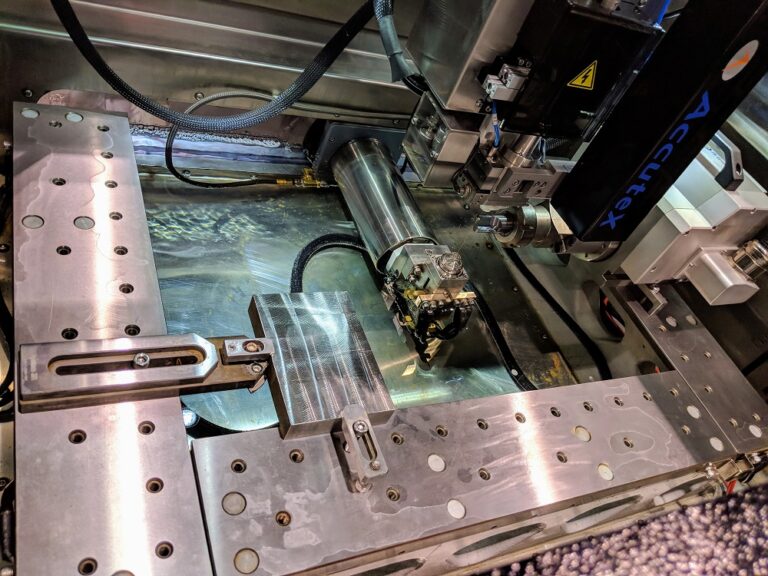

For more than 30 years, Absolute Machine Tools has been helping machine shops and manufacturing facilities improve their production processes to be more competitive in an ever-changing global environment. This includes reducing expenses and production down time by providing tough, high quality tools designed to have the longest tool life possible.

Tool life is a term used to describe the duration of time a tool is useful. CNC machine tools are expensive to replace, so machinists are always looking for ways to extend the operational life of their tools.

Types of Tool Wear

Using a tool causes wear to the tool. Too much wear leads to tool failure. There are several types of wear that impact a tool’s lifespan, including:

Production Stress Affects Tool Life

Stresses placed on the tool during the production process can cause wear that decreases the useful life of a tool. Factors such as cutting speeds, cutting types (continuous vs. intermediate), the feed and depth of the cuts, tool geometry, cutting fluid used and the rigidity of the machine can all shorten a tool’s life.

Tool Material Affects Tool Life

The materials the tool is made of also plays a big factor in how long a tool can be used. It should be properly machined and made from a material strong enough to perform the required job. In addition, there are also a variety of surface treatments available to increase surface hardness and wear resistance.

Carbon and Alloy Steels and Tool Life

Carbon and alloy steels are used for many manufacturing applications in the aerospace, agriculture, automotive, construction/mining, energy, medical, and military/defense industries.

Steel with a low carbon content is malleable and ductile, as well as being relatively inexpensive. Medium carbon steel combines the ductility and strength with better wear resistance. High carbon steel is exceptionally strong, while ultra-high carbon steel can be tempered to extraordinary hardness.

As you can imagine, the variations in physical and chemical properties in carbon and alloy steels can impact the life of a tool in different ways.

Physical properties of carbon and alloy steel work materials that can affect tool life include:

Chemical properties of carbon and alloy steel work material that can affect tool life include:

In order to get the most use out of your tools, it’s important to take all the factors that affect tool life — production requirements, tool materials and work materials — into consideration.

Cost-effective Engineered Solutions – Guaranteed!

Absolute Machine Tools is a leading importer and distributor of CNC machine tools in North America. Since 1988, we’ve been providing the highest quality production machining, mold/die machining, high-speed machining, conventional turning, Swiss turning, wire EDM, die sinkers, hole poppers, and deep hole drilling/finishing tools to CNC machining facilities all over the U.S. and Canada.

If you’re looking for long lasting CNC machine tools, contact Absolute Machine Tools and let our sales and application engineers help you find the right machine for your needs!