Solutions from Absolute Machine Tools

River ZNC (Z-Axis NC) Hole Drilling Machines

These high-speed small-hole EDM drillers combine digital Z-axis control with stable machining performance for a wide range of wire-start and general drilling applications. Designed to handle workpieces up to 600 kg, ZNC models deliver consistent accuracy and clean burn quality in demanding materials.

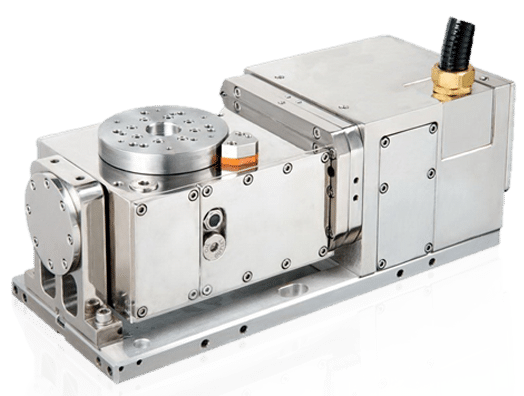

River CNC Ram-Type Hole Drilling Machines

For more advanced applications, River CNC systems provide 3- to 6-axis capability, W-axis tilting heads for angled or shaped-hole drilling, and optional milling functions for complex aerospace and medical geometries. Precision linear motion, intelligent CNC control, and automation readiness make these machines ideal for high-tolerance multi-hole drilling and production environments.

Together, River EDM CNC and manual hole-drilling machines provide the stability, speed, and automation flexibility required for modern EDM operations.

Absolute Machine Tools provides complete EDM solutions from installation to optimization. Our dedicated EDM applications engineering and service team supports every River EDM system with expert training, available test cuts, time studies, and free lifetime training to ensure long-term success and maximum machine utilization. Contact us today to discuss your EDM drilling requirements or schedule a test cut.