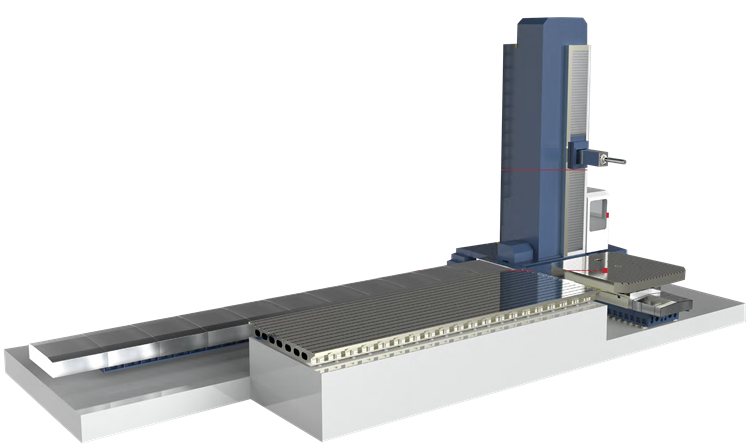

Floor-Type

Boring Mills

Long-Travel, High-Rigidity CNC Boring Performance for Oversized Components

Floor-type boring mills deliver the extreme rigidity, long-axis reach, and deep-cutting power required for machining very large and heavy components. With a moving-column X-axis and a fixed table structure, these CNC boring mills provide exceptional stability for deep boring, heavy roughing, multi-face machining, and extended-travel operations where precision over long distances is essential in oil & gas, energy, aerospace, shipbuilding, and heavy equipment production.

Absolute Machine Tools offers new CNC floor-type boring mills engineered on massive Meehanite castings with high-torque gear-driven spindles, oversized rams and quills, and long-travel moving columns. These machines are built for consistent, repeatable accuracy during deep-reach machining and continuous heavy-duty cutting on oversized workpieces.

Benefits for Metal Cutting Manufacturers

- Long-travel moving column provides accuracy over extended X-axis paths

- Ideal for machining very large parts that exceed table-type limitations

- Exceptional rigidity for deep boring, heavy roughing, and high-load cutting

- Fixed table architecture supports massive workpieces with maximum stability

- Designed for applications requiring deep reach, large envelopes, and high torque

- Better geometric accuracy for long-distance spindle positioning

Machines

Johnford FBMC Series – Floor-Type Horizontal Boring Mills

Moving Column X Axis with Fixed Table-Type Design & V-Axis Rotary Table

Solutions from Absolute Machine Tools

Johnford

Johnford floor-type boring mills combine massive Meehanite castings, wide box-way construction, and high-torque gear-driven spindles to deliver long-travel accuracy and rigidity on extremely large workpieces. Their moving-column X-axis and fixed-table design maintain stability over extended machining distances, enabling precise deep boring, heavy roughing, and multi-face machining on oversized castings, energy components, structural weldments, and large industrial bases. Engineered to rival the performance of leading global platforms from Fermat, TOS Varnsdorf, and Giddings & Lewis, Johnford delivers comparable long-travel accuracy, rigidity, and cutting capability at a significantly lower investment cost, making it one of the most cost-effective choices for shops that require large-envelope machining without the premium price tag typically associated with traditional floor-type boring mills.

Absolute Machine Tools supports every floor-type boring mill installation with engineering assistance, applications expertise, automation integration, and responsive service. Contact us today to review your part requirements and request a quote for a CNC floor-type boring mill designed for your largest and most demanding machining challenges.

Pictures of Floor Type Boring Mills