High-Rigidity CNC Boring Mill Platforms for Large-Part, High-Torque, Precision Machining

Horizontal boring mills remain the machine of choice for manufacturers producing large, heavy, and complex components that demand exceptional stability, long-travel accuracy, and high spindle torque. These CNC boring mill platforms deliver the power required for deep-hole boring, heavy roughing, precision drilling, tapping, and multi-face machining where conventional machining centers simply cannot maintain accuracy. Built for oversized workpieces, challenging materials, and continuous high-load conditions, horizontal boring mills support mission-critical production in oil & gas, energy, aerospace, heavy equipment, transportation, and industrial machinery sectors.

Absolute Machine Tools offers a complete portfolio of new CNC boring mills engineered for maximum rigidity and long-term accuracy. Featuring massive Meehanite castings, full-contact box-way construction, high-torque gear-driven spindles, long-travel axes, and thermally stable moving-table or moving-column designs, our boring mills provide the reliability and machining flexibility required for demanding applications that competing platforms struggle to match.

Benefits for Metal Cutting Manufacturers

Machines

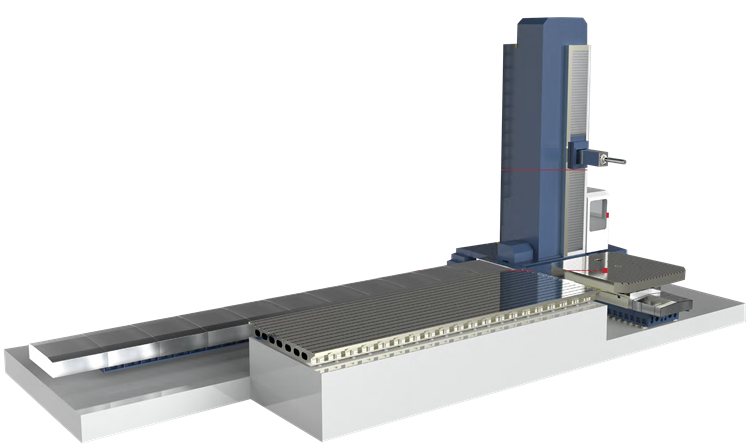

Floor-Type Horizontal Boring Mills

Moving Column X Axis with Fixed Table-Type Design & V-Axis Rotary Table

Solutions from Absolute Machine Tools

Johnford

Johnford horizontal boring mills deliver the rigidity and precision required for machining the largest and heaviest components, using extremely heavy Meehanite castings and wide box-way systems that outperform many competitor platforms. Their table-type design uses a fully supported moving table and a moving column to maintain precision across long travels, even when cutting workpieces exceeding 50,000 lbs. High-torque gear-driven spindles, deep quill capability, large rotary tables, and standard linear scale feedback allow Johnford boring mills to tackle deep-hole boring, heavy roughing, and precision finishing with consistent accuracy. The floor-type models extend Johnford’s capability even further with long-travel moving-column designs engineered to rival solutions from Fermat, TOS Varnsdorf, and Giddings & Lewis, providing the rigidity and reach required for large castings, structural weldments, energy components, and other oversized parts that demand high-stability machining.

You Ji

You Ji horizontal boring mills combine heavy Meehanite construction with full-contact box-way design and high-torque gear-driven spindles to deliver exceptional rigidity during heavy cutting and long-cycle operations. Their moving-table and moving-column structure provides stable support for extremely heavy workpieces while maintaining long-term geometric accuracy across extended travels. With the torque needed for deep boring and the stability required for precision finishing, You Ji CNC boring mills are ideal for machining aerospace fixtures, large tooling blocks, industrial machinery components, welded fabrications, and other oversized workpieces that require repeatable accuracy. Their proven reliability in demanding global manufacturing environments makes them a strong alternative to well-known boring mill brands across Asia, Europe, and North America.

Absolute Machine Tools supports every horizontal boring mill installation with expert engineering, dedicated applications assistance, automation integration, and responsive service to maximize uptime and productivity. Contact us today to review your part requirements, compare platform options, and request a quote for a CNC boring mill that gives your shop a competitive advantage.