Absolute Machine Tools maximizes profitability in the precision production turning industry by matching the right part to the right machine. This means partnering with our engineering staff to analyze part complexity, materials, tooling, tolerances, and lot sizes, to match the best machine to those requirements.

Absolute has hundreds of years of combined experience doing just that. We offer 3 versatile brands specifically engineered

for chipmaking production processes.

Nexturn Swiss Lathes

Nexturn CNC Swiss lathes include both exchangeable and non-guide bushing models with maximum bar capacities from 12mm to 51mm. Nexturn turret-type non guide-bushing fixed headstock machines process 45mm, 56mm and 67mm diameter bars.

LICO CNC Screw Machines

LICO multi-axis multi-slide CNC screw machines offer overlapping of up to 5 tools in the cut simultaneously rivaling screw machine speed with CNC quality and versatility.

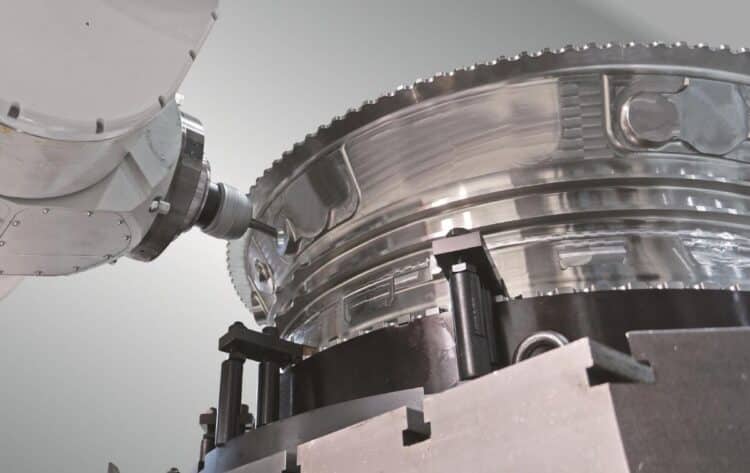

QuickTech CNC Mill/Turn Centers

QuickTech multi-tasking, multi-function CNC mill/turn centers are equipped with up to 56 total tools and 24 B-Axis live tools. With up to 10 axes working simultaneously between the main and sub-spindles and bar capacities up to 65mm, these machines can drop complete parts quickly with no secondary operations, saving labor and increasing profitability.

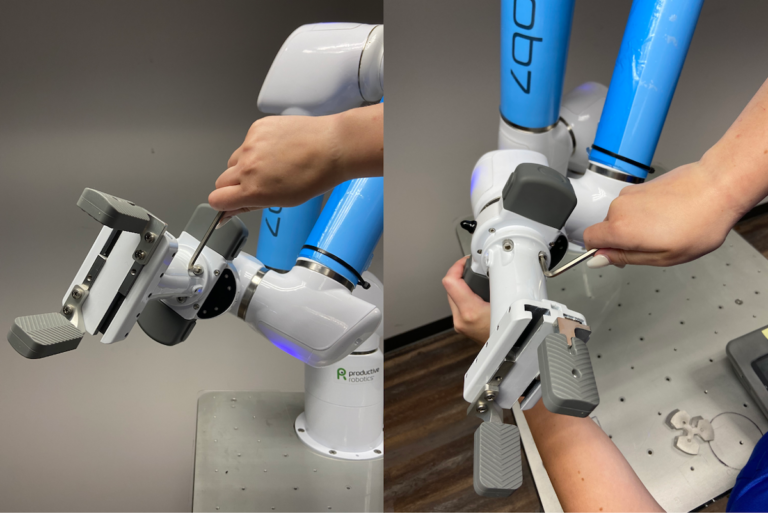

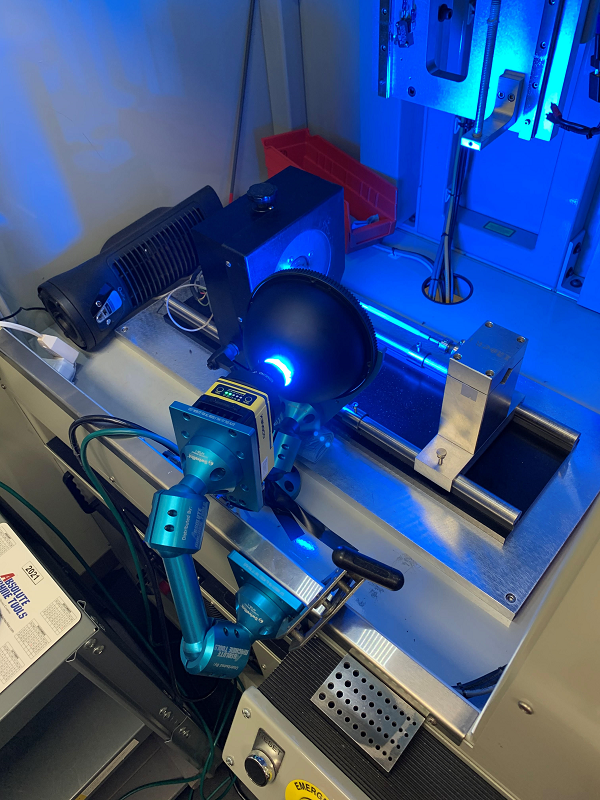

All of these brands can be easily and inexpensively robot loaded or bar feeder loaded for minimizing labor cost in production turning jobs.

Email us today at info@absolutemachine.com to learn more!