High-quality CNC machines last many years. So if you’ve recently purchased a new machine, it’s possible it’s just been a long time since you’ve had to get ready for a new CNC machine installation.

At Absolute Machine Tools, we strive to make the process of delivering and installing your new machine tool expedient, accurate and easy for our customers. To that end, here are some tips to make the process as seamless as possible.

1. Is Your Electrical Supply Sufficient?

Different machines may require different electrical input, so check with your salesman on the specifications of your new machine tool to ensure you are prepared for this. Also consider the location of your electrical source. Will it be easily accessible from where you intend to place your CNC machine?

2. Is Your Layout Planned?

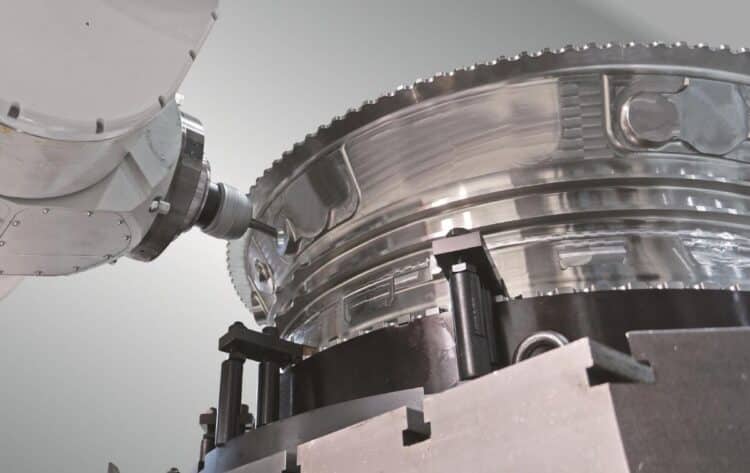

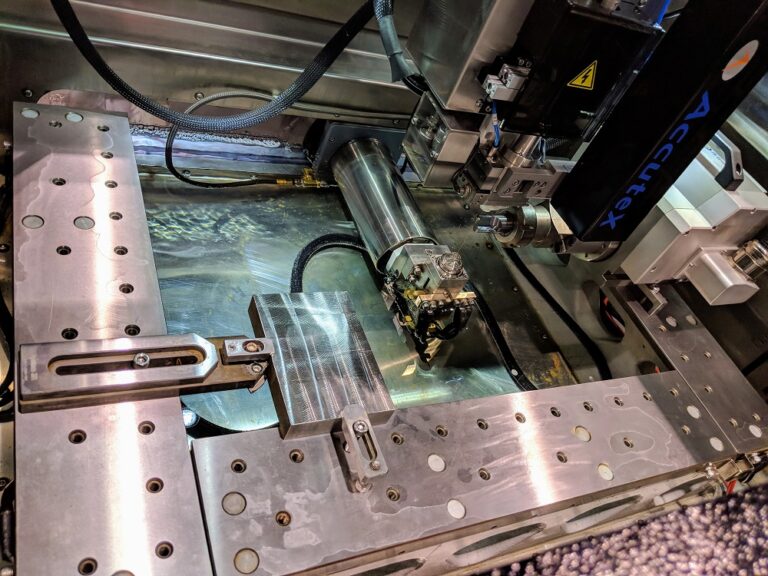

From massive bridge mills to compact CNC lathes, we offer a wide range of sizes in CNC machines, depending on what you need the machine to do and what kind of spacing you have. You’re salesman will have already taken into account your spacing needs during the process of working with you on the purchase of your new machine tool, but it’s not always just the size that matters.

Sometimes the layout of your job shop can affect how successful a CNC machine installation is. Consider things such as door clearance, closeness to walls or other structures in the shop, whether you can access all parts needed to perform regular maintenance, etc.

3. Check Your Foundation

CNC machines are heavy — even the compact machine tools. A concrete floor that is too thin, or situating your machine in a location where it isn’t on one solid slab can lead to issues with accurate cutting. Talk to your salesman about required flooring to make sure this won’t be an issue.

4. Manage Your Humidity

If the air in your shop is too humid, it can lead to premature rust inside your new machine tool, which can lead to a host of problems with machine performance. We want your CNC machine installation to be the next step in improving quality, minimizing expenses and maximizing profits for your job shop. Managing the moisture level in the air is an easy way to make sure your machine tool will continue to serve you well for years to come.

5. Get the Right Fluids

Check with your salesman to ensure you have all the necessary fluids for proper machine operation, such as lubricating oil, coolant, hydraulic oil, etc. Not using the correct products can cause serious damage to your new equipment. We want your machine to be up and running at it’s best on the day of installation!

Want to know whether your job shop can accommodate a machine tool you’ve had your eye on? Give Absolute Machine Tools a call today at 800-852-7825!