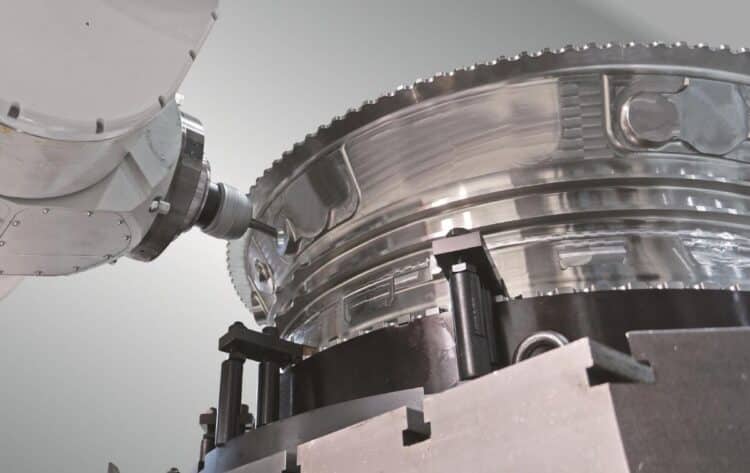

Manufacturers are always looking for ways to increase productivity while reducing costs, which is one of the main reasons more and more CNC shops are making the transition to “lights-out” operations.

“Lights out” manufacturing is a manufacturing process that utilizes automation in conjunction with human labor to keep equipment running 24 hours a days, 7 days a week. It’s called “lights out” because an automated facility can continue to run even after the lights (and heat and AC) have been turned off at the end of the work day.

Advantages of Lights-Out Manufacturing

Lights-out manufacturing isn’t a new idea. The Japanese robotics company FANUC has been operating a lights-out robotic factory since 2001. Using automation to increase production while reducing operating costs has been a goal of manufacturers since the beginning of the Industrial Age. The term “lights-out” was first used in the eighties and is credited to late General Motors CEO Roger Smith, who used the term to describe a fully automated manufacturing process that would make GM competitive with their Japanese rivals. Advances in robotic technology has made workplace automation less expensive and more efficient, spurring the current lights-out manufacturing trend.

As you can imagine, there are many advantages to going lights-out:

If you’re a CNC machinist, don’t panic. Even as CNC manufacturing moves towards automation, humans are still needed for quality control, job planning, scheduling, machine maintenance, logistics and more.

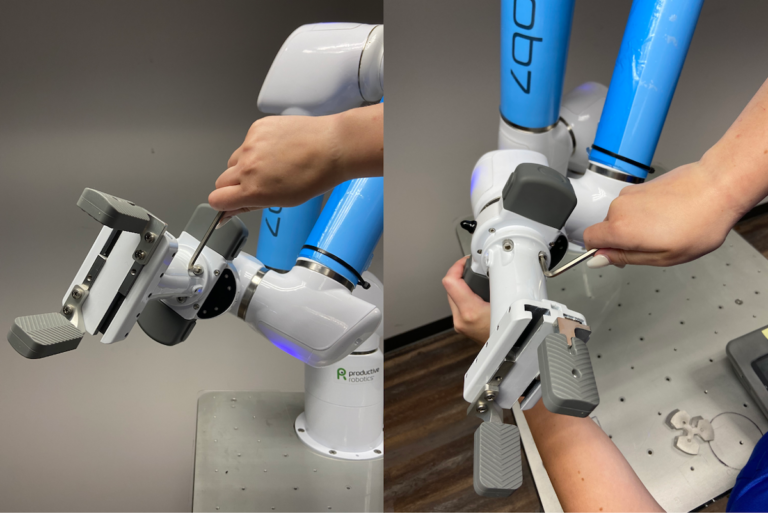

Products like the OB7 Cobot are making it Easier to Go Lights-Out

Productive Robotics’ OB7 “cobot” is an excellent example of the type of workplace automation products that are enabling CNC manufacturers to make the transition to lights out operations. The OB7’s specially designed seven-axis robot arm makes it almost as articulate as a human arm. The arm gives the robot the ability to reach over, under, and around objects.

The OB7 integrates directly into a current manufacturing operation; no production line re-engineering is required. Sensors allow it to work alongside humans without being fenced off or contained. In addition, the OB7 has the ability to learn new jobs from its human co-workers and doesn’t require any special programming. The OB7 is also relatively inexpensive (prices start at just under $35,000) and provides a rapid return on investment.

Is Your Operation Ready to Go Lights-Out?

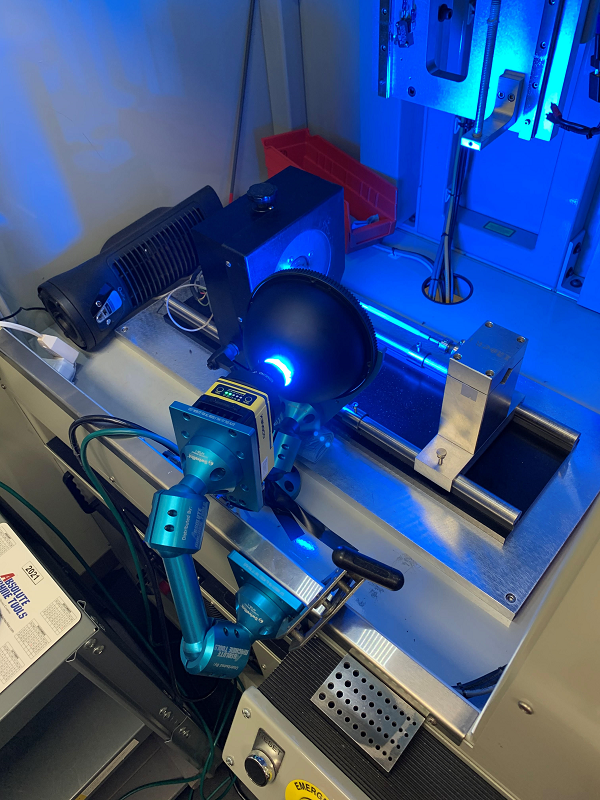

Lights-out manufacturing is changing the way CNC facilities operate. If you’re looking for ways to integrate lights-out technology into your manufacturing process, Absolute Machine Tools is here to help.

For over 25 years, Absolute Machine Tools has been providing U.S. CNC manufacturers with the state-of-the-art tools they need to stay ahead in an ever-changing business environment. This includes the latest in CNC technology and automation solutions, such as the OB7 cobot.

Our mission is to help your business succeed in a global market that is increasingly turning to automation for a competitive edge. Contact us at 800-852-7825 or email info@absolutemachine.com to learn how Absolute Machine Tools’ innovative products and services can help you expand your CNC operations and increase profits.