Precision is not just a requirement in medical implant manufacturing, it’s the lifeline that bridges innovative design with life-saving functionality. The transition from manual craftsmanship to precision manufacturing has been pivotal in the development of medical implants. Even the slightest deviation in size, shape, or placement can significantly impact an implant’s functionality and compatibility with human biology. Early implants faced challenges like poor fit, rejection, and limited functionality, often due to the limitations in manufacturing accuracy and consistency.

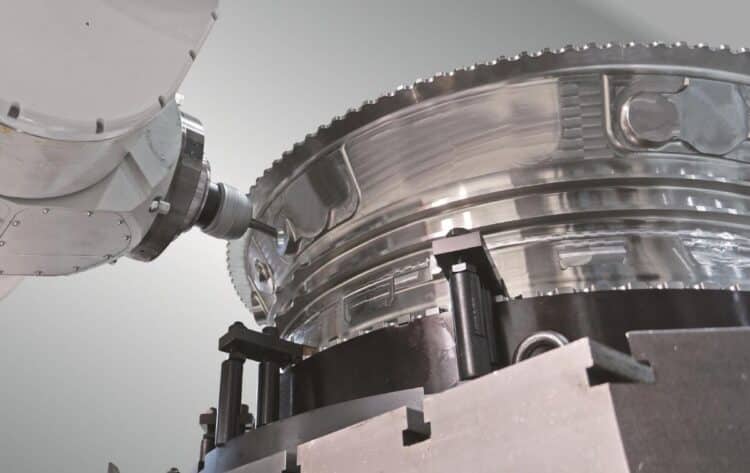

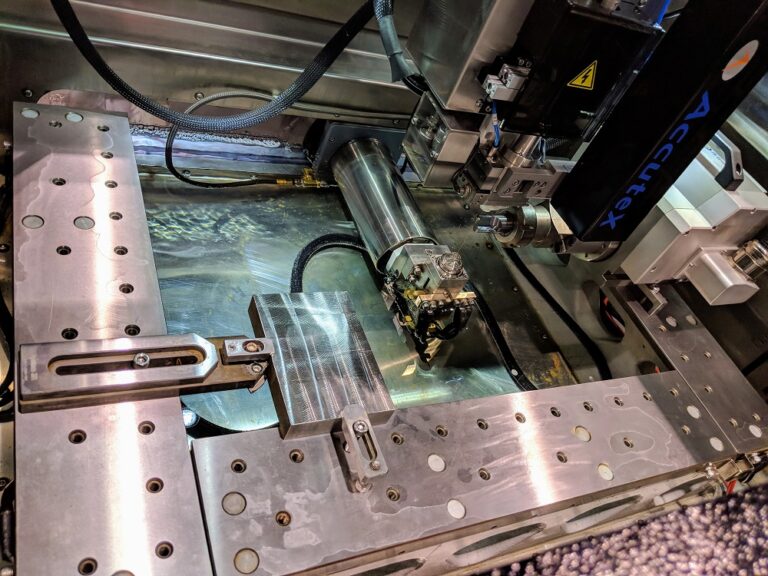

As the medical field advances, the demand for more sophisticated implants grows, calling for manufacturing solutions that can navigate the complexities of modern medicine with finesse and accuracy. Enter the GVN06 micro gun drilling machine by Precihole, a game-changer in the realm of medical implant production. This state-of-the-art machine is setting a new industry standard, enabling manufacturers to achieve unprecedented levels of precision and efficiency in small hole drilling.

The GVN06 is designed specifically to meet the rigorous demands of medical implant manufacturing. With its introduction, Precihole and Absolute Machine Tools are revolutionizing the way medical implants are made, paving the way for advancements that promise to improve patient outcomes and quality of life.

Medical Implants Made Possible By Micro Gun Drilling

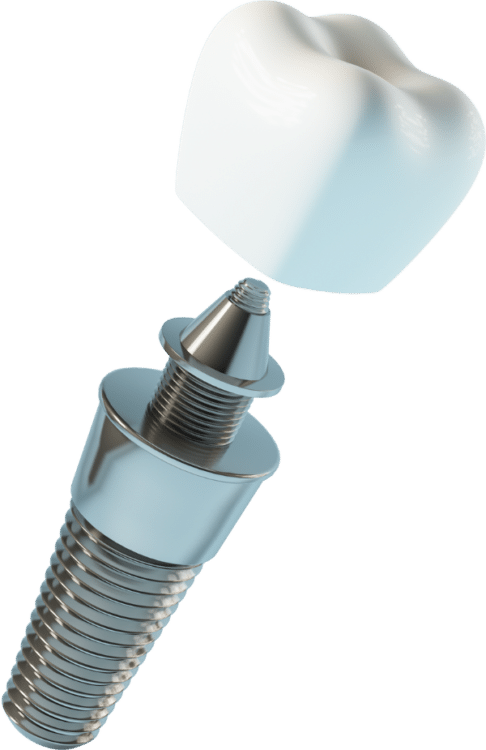

In medical implant technology, the emphasis on precision cannot be overstated. Each implant, whether it’s intended for orthopedic, dental, cardiac, or any other use, must adhere to exacting standards to ensure its functionality, durability, and biocompatibility. The intricacies involved in creating these life-enhancing devices often necessitate the drilling of micro holes with utmost precision — a task where even a minor discrepancy can lead to significant consequences. The GVN06 micro gun drilling machine by Precihole emerges as a pivotal technology in this context, bringing unparalleled precision and reliability to the manufacturing process.

Manufactured medical implants may require small holes to be drilled into them for various reasons, including implantation, fixation, or functionality. Some examples of human implants that may require small holes include:

These examples illustrate the diverse range of human implants that may require small holes for various purposes, including implantation, fixation, and functionality. Each implant is designed to address specific medical needs and may involve different surgical techniques for implantation and placement.

Challenges of Precision Drilling

Achieving the necessary precision for these micro holes presents several challenges, including maintaining the structural integrity of the material, ensuring the cleanliness of the drilled holes, and achieving the required tolerances. Traditional drilling methods often fall short in meeting these rigorous standards, leading to increased production times, higher costs, and, in some cases, compromised device performance.

Precihole’s GVN06 Micro Gun Drilling Solution

The Precihole GVN06 micro gun drilling machine addresses these challenges head-on, offering features specifically designed for the needs of the medical implant industry. Its ability to drill holes ranging from 1mm (0.04″) to 6mm (0.25″) with exceptional accuracy and surface finish ensures that implants meet the strictest quality standards. Additionally, the machine’s high-speed drilling capabilities and advanced coolant system facilitate efficient chip evacuation, minimizing the risk of contamination and maintaining the integrity of the drill site.

Features and Benefits of the GVN06 Micro Gun Drilling Machine

The GVN06 micro gun drilling machine by Precihole is at the forefront of drilling technology, specifically designed to meet the demanding requirements of the medical implant manufacturing industry. Its integration into production lines represents a significant advancement, enabling manufacturers to achieve levels of precision and efficiency previously unattainable. Below, we detail the key features of the GVN06 and the benefits they bring to the field of medical implants.

By choosing the GVN06, manufacturers are investing in a technology that will elevate the quality of medical implants and, ultimately, patient care.

Elevate Your Medical Implant Manufacturing Excellence

At Absolute Machine Tools, in partnership with Precihole, we understand the critical role that advanced manufacturing technology plays in the medical industry. Our team is ready to support you in integrating the GVN06 into your operations, ensuring you harness its full potential to meet the exacting standards of medical device manufacturing.

Don’t let the limitations of conventional drilling techniques hold you back. Explore how the GVN06 can transform your manufacturing processes and help you lead the way in medical innovation. Contact us to learn more about the GVN06 micro gun drilling machine, schedule a demonstration, or discuss how we can support your manufacturing ambitions.