Automation is one of the biggest trends in the CNC machining industry, as more and more companies discover that integrating robotics with their CNC machine tools increases productivity while decreasing costs.

A leader in the field of CNC automation, Absolute Machine Tools distributes state-of-the-art robotics to customers in North America. Productive Robotics’ OB7 is a revolutionary 7-joint robot arm that’s taking the industry by storm because it is the world’s only 7-axis cobot on the market today!

Read on to find out how OB7 can make your CNC operations more efficient and profitable!

OB7 Features

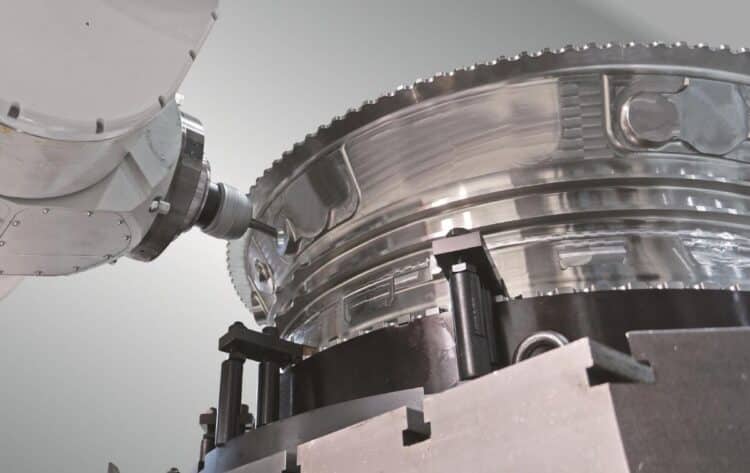

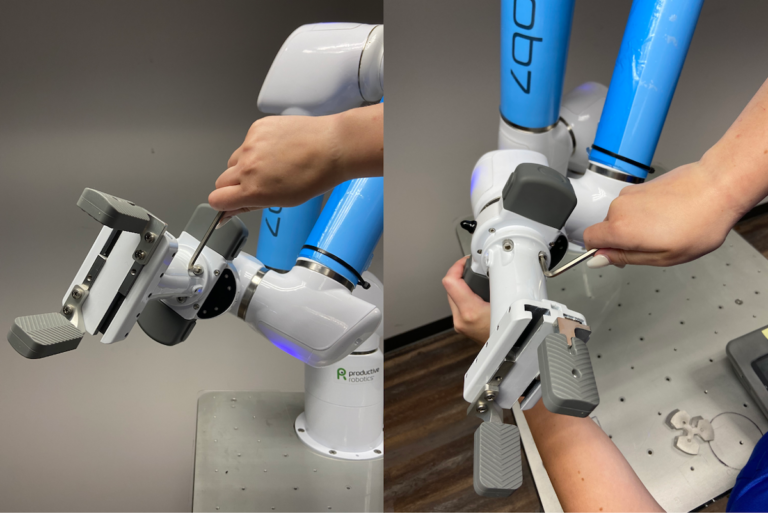

Two of the OB7’s most unique features are its 7-axis arm and its ability to learn a task without requiring special programming like G or M code. The 7-axis arm provides for greater freedom of movement, allowing it to reach around the machine’s door and into a machine to load/unload. Unlike a 6-axis robot arm, the OB7 is perfect for maneuvering in confined spaces and doesn’t have to be positioned directly in front of the machine door, which makes it easier for human operators to access the work envelope area for things like changing tools or making adjustments.

The OB7 can also learn tasks without the need for programming; operators simply “teach” OB7 a new operation using hand-controlled motions and command templates stored in the robot’s control tablet.

Other standard features included in the CNC package:

As you can imagine, there are many benefits to integrating the OB7 into your CNC operations. Some of the ways the OB7 can increase the efficiency and profitability of your operations include:

OB7 Integrates Directly into Your Current Manufacturing Operations

You can use the OB7 to automate almost any task. The OB7 works and communicates with all brands of CNC machines. It can be seamlessly integrated into your current manufacturing operations, so you won’t have to reengineer your production line to accommodate it, or pull an operator from another area.

The OB7 is classified as a “cobot” (collaborative robot) — fully compliant with ISO 10218-1 work safety guidelines and requirements and designed to operate alongside human workers without the need for safety fencing or caging, although OB7 is capable in working in “robot” mode as well. OB7 is the perfect solution for running both high volume and small runs, but it’s best for small parts batches because it runs consistently and without a person. As stated earlier this allows for greater flexibility in a shop’s workforce.

The OB7 Is On-The-Job 24/7

The OB7 doesn’t require direct human supervision. This means you can keep it working 24/7, without breaks or downtime, greatly expanding your production capabilities (and keeping overtime costs low). The OB7 will alert you on your cell phone if operating problems arise.

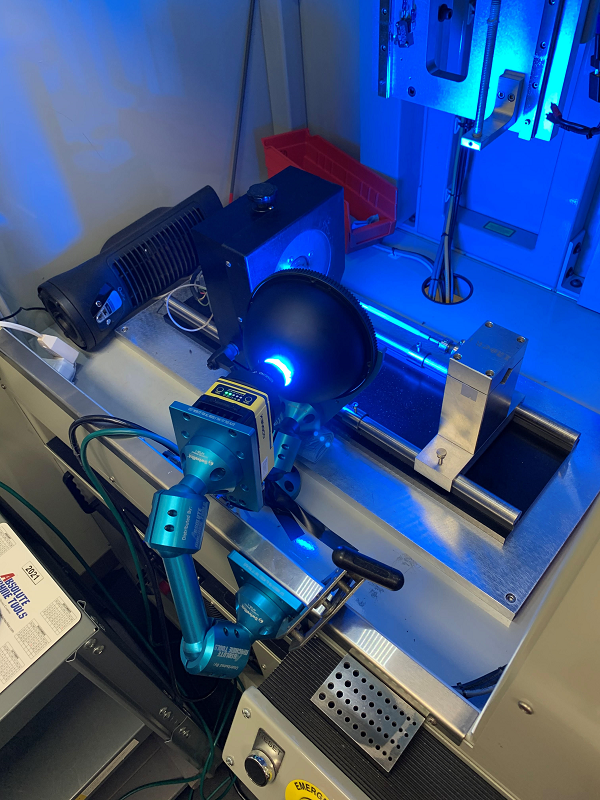

The OB7 is Useful for a Wide Range of CNC Machining Applications

The OB7’s versatility means it can be used for a number of CNC machining applications to increase production, consistency, quality and yield:

OB7 Is Easy to Set-up and Operate

You’ll have the OB7 up and running in no time. Instructions are entered using a control tablet, and the OB7’s hand controls for simple drag and drop user interface makes it easy to teach the robot new jobs.

No software to download or the need for G-code or M-code programming (CNCs need only one M-code in the control for interfacing) — your staff can teach OB7 how to perform any job task, within minutes, using a few simple commands. And it only needs to be taught once. The OB7 learns quickly and can store thousands of job details into memory.

OB7 Improves Productivity

The OB7 increases worker productivity and quality. By letting the OB7 handle the boring, repetitive tasks, you free up your staff to concentrate on the more important, higher value work, and possibly get training in areas that they otherwise don’t have time for.

OB7 Delivers Rapid ROI

The OB7’s versatility, ease of set-up and operation, and 24/7 operating capability provides numerous advantages that can save your business time and money. In many ways, purchasing the OB7 can be more cost-effective than hiring an additional employee, since you won’t have the ongoing costs of payroll, taxes, benefits, PTO, etc. Most businesses can expect to see a Return-On-Investment (ROI) with OB7 in less than six months.

Contact Absolute Machine Tools to Learn How the OB7 Can Help Make Your CNC Operations More Efficient!

Manufactured and designed in the USA, the OB7 provides a simple, smart, and affordable robotic solution for automating your CNC operations. Contact Absolute Machine Tools to learn how the OB7 can make your CNC operations more efficient and profitable by emailing to QuoteMyOB7@absolutemachine.com today.

We’ve been delivering cost-effective engineered solutions to companies all over the U.S. since 1988. Our mission is to help your business succeed in a global market that is increasingly turning to automation for a competitive edge.