There is a myth in manufacturing that robots are only needed for high volume parts manufacturing. Robots whose speeds are measured in g-force with cages around them can outproduce any human. However, this truly is no longer the case, and cobots are changing that perception.

When BIC Precision in Blanchester, Ohio, was approached by their customer to produce 5,000 to 7,000 total parts per year, in batches of 500, they jumped at the opportunity. How hard can it possibly be to make approximately 130 parts over a couple of days? They have a machinist who can do this while running other machines … doesn’t every shop? Today, employees in machine shops wear many hats, and often they run more than one machine. That is the same scenario with BIC.

The Struggle for Consistent Production

But BIC soon found out that, while they could run that many parts a day, things often came up unexpectedly. They began to see their daily output goal dwindle. Some days, they made 70 parts; some days, 110. On a good, consistent day, they made all 130 parts.

Many shops have experienced this same kind of inconsistency with small to medium volume parts runs. These variances can be costly, causing stress, accidents, overtime or — even worse — bad parts from rushing a job.

BIC Precision had to find a way to avoid this problem. They looked to Absolute Machine Tools for help.

Finding a Solution

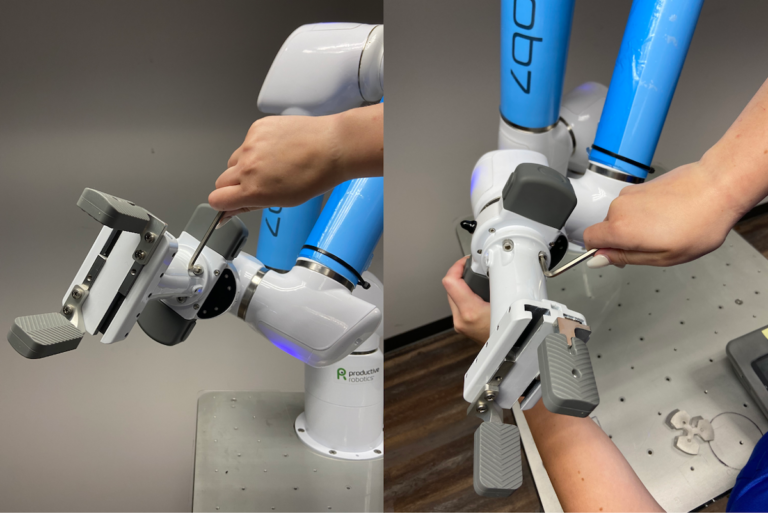

Our solution to the problem? The OB7 Cobot from Productive Robotics.

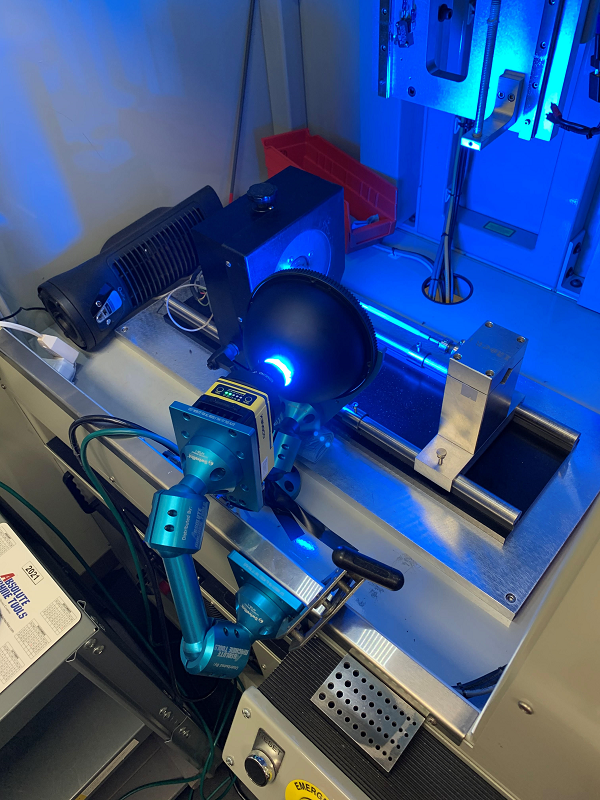

The OB7 was installed and interfaced with 2 of BIC’s Doosan lathes. OB7 removes parts from one lathe and loads them into the other lathe for secondary operations. OB7 runs consistently for BIC all day and night, until it runs out of parts to load.

This has not only helped BIC to fill this particular parts order, but it has also allowed them to accept a new larger piece order from the same customer. Not only has OB7 increased their production capabilities, it has also freed up the machinist who was trying to run that job and others. He is now free to use his skills for more value-added tasks, helping the company’s overall profitability.

Cost-effective Engineered Solutions – Guaranteed!

All shops have production runs that, with the right integrator, can have the same results BIC has had. BIC was smart: They took time to consult with Absolute on tightening part production by evaluating their processes and found a way of getting maximum results with minimal investment.

If you have small but consistent part runs and would like to learn how you could improve your production processes, give Absolute Machine Tools a call at 800.852.7825 and let us evaluate your needs and offer solutions. Absolute Machine Tools’ engineered solutions specialists are committed to your shop’s success!