CNC machine maintenance may seem like a boring chore compared to the other tasks of running a successful machine shop. When a machine breaks down, it can cost a business owner thousands of dollars, not only for the cost to repair the breakdown but in lost profits too. In those moments of exasperation, missed maintenance can be maddening. With lots of mechanical moving parts and high tech pieces, breakdowns are inevitable. However, a short consistent checklist and long term preventative plan can help reduce the risk of costly stoppages.

Daily CNC Machine Maintenance

These are the “apples a day” that keep your CNC machine tools out of the machine emergency room. They sound simple, and they are. Doing a few minor checks at the end of each day or each shift can help catch a problem before it snowballs into a major breakdown. The machine tool specialists at Absolute Machine Tools recommend the following daily maintenance schedule:

Spring Cleaning For Milling Machines & Lathes

When performing a thorough spring cleaning on your milling machines:

When performing a thorough spring cleaning on your lathes:

For both types of machines, it is highly recommended that filters be checked or changed often to ensure overall integrity of your systems.

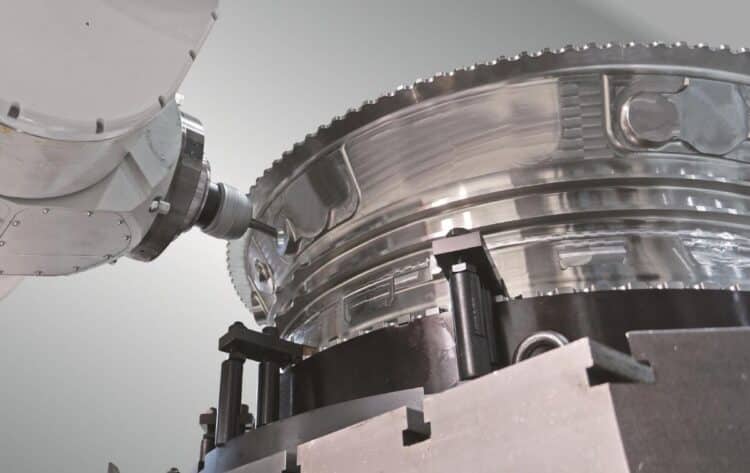

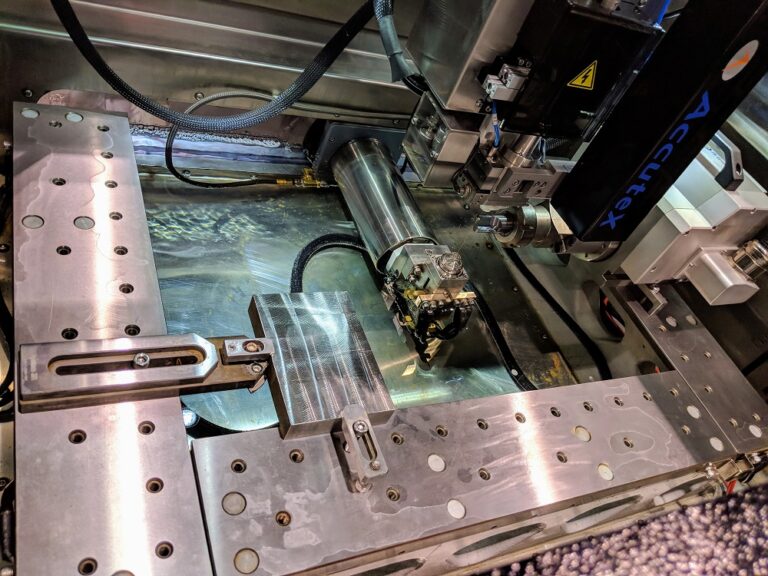

Absolute Machine Tools has the proper equipment for CNC machine tool inspection and preventive maintenance or spring cleaning: Renishaw Ballbar for circularity, Renishaw Laser for pitch error compensation, Hamar Triple Scan Laser for alignment and Faro Tracker Laser for alignment.

Preventative Maintenance Plan

A preventative maintenance plan (PMP) is vital to keeping shop machines running and making money. Routine check-ups boost output efficiencies, increase uptime and improve profit margins. Not convinced? Try this on for size: unplanned breakdowns of CNC machines typically cost 5 times more than annual PMPs. Between expedited part shipment and wasted hours, a PMP wins every time for cost effective machine maintenance.

Absolute Machine Tools offers three levels of PMPs, sure to fit any shop budget and can be performed on any brand. Our Gold Premier Package is a 15-point checklist designed to maintain CNC machines for many years of use. By checking accuracy, repeatability and part integrity, our Gold PMP sets the standard for elite maintenance. The Silver package is a 13-point plan that covers all the major extended service needs, and the Bronze package makes 10 high need checks for shops on a tighter budget.

All three of our preventative maintenance plans will help keep your CNC machines running. Shops that choose to do in-house maintenance can still use Absolute for parts. The service department at Absolute Machine Tools has invested more than $20 million dollars in spare and miscellaneous parts for CNC machines. Call us today for any CNC machine maintenance needs.