Absolute Machine Tools will demonstrate an automated gun barrel cell at IMTS 2022 in Booth #338519! This cell consists of a Precihole GVN Series Single-Axis 4-Spindle CNC Gun Drill and FANUC M-710iC industrial robot.

“Increased demand for gun barrel production worldwide has continued to compound,” said Nicole Conrad, Chief Marketing Officer, Absolute Machine Tools. “Precihole is well-known for their high-precision gun drilling machines so combining the GVN Series into an automated cell using the FANUC M-710iC robot expands and increases gun barrel production meeting the needs of gun manufacturers drilling for small and large-caliber gun barrels.”

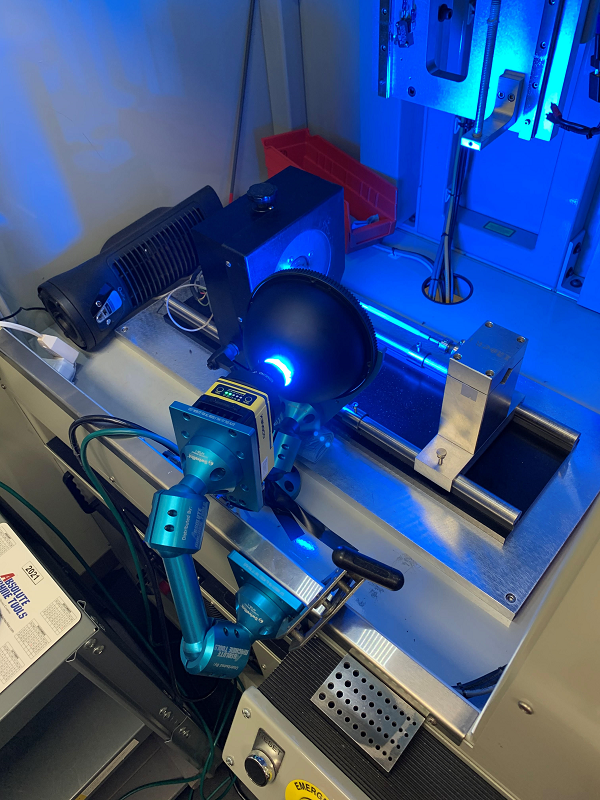

About GVN Series Gun Drilling Machines

The GVN Series is engineered specifically to manufacture high-precision parts for small-caliber gun barrels. Available in five models – the GVN06, GVN08, GVN12, GVN25 and GVN 40 – these machines can be customized to meet high-volume requirements. They are available with one to four spindles, ranging from 2HP to 20HP depending on the model, for exceptional straightness, surface finish and bore tolerance. Length-to-diameter ratios of up to 125 are possible with this system. Drill speed range is 0” to 40” per minute.

The GVN Series uses counter rotation and ball screw and servo drives to provide linear motion for excellent straightness during drilling. Spindle speeds range from 1,000 to 12,000 RPM depending on the model. The GVN06C model features an ultra-high speed precision motorized spindle. Multiple tool steady rests result in solid tube support. Optional Hydraulic Cone/Self-Centering Chucks are available for proper part clamping. With maximum drilling depths of 12”, 16”/24”/40”/48” and 16”/24”/40” relative to the machine being used.

All models use a high-pressure coolant and fine filtration system to ensure clean machining while an oil chiller and automation lubrication make sure tools are running smoothly.

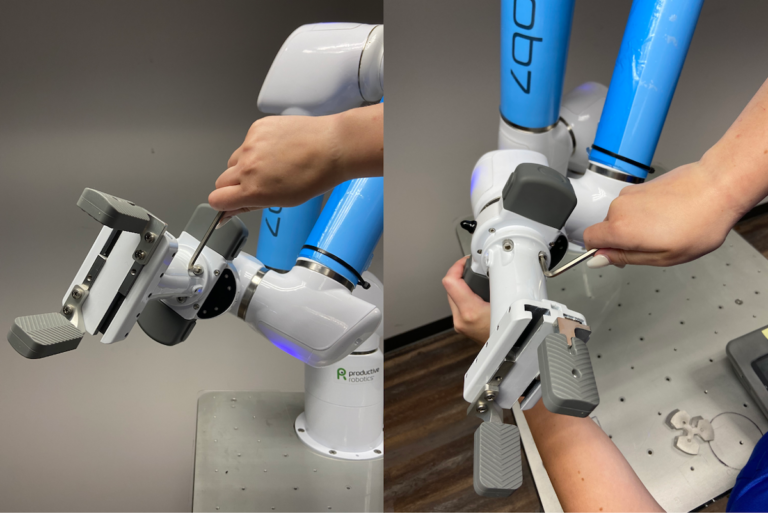

About the FANUC M-710iC Industrial Robot

The FANUC M-710iC industrial robot has 6-axes and can hold up to 50kg maximum payload. Repeatability is +/- 0.03mm and can be mounted to the floor, upside down, or at an angle. The FANUC M-710iC robot has a maximum reach of 2050mm and is built to handle long heavy material due to its smart wrist design, having motors and other electrical elements typically built into the wrist area mounted rather in the shoulder or J3 of the robot.

The FANUC M-710iC industrial robot is best used in applications such as assembly, arc welding, spot welding, pick/pack/palletizing, load transfer, material removal, and dispensing. The large range this robot provides including it’s 50Kg payload capacity makes this robot a smart choice for any gun barrel manufacturer swinging long heavy blanks and finished barrels in and out of the machine.

Learn More About the Gun Drilling Automation Cell

For more information, visit Absolute Machine Tools at IMTS 2022 booth 338519 or call us today at (800) 852-7825.