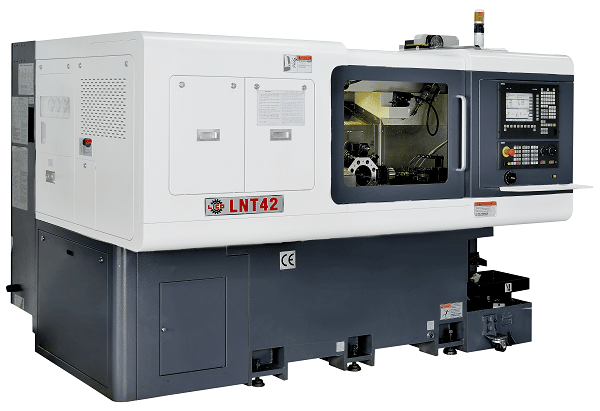

Greg Knight, Absolute Machine Tools’ VP of Sales Production Turning Products, recently discussed the evolution of the precision production turning industry in an article in Production Machining magazine titled “Production Turning to CNC.”

“The primary reasons shops are moving away from cam-actuated machines include equipment age and condition, and a limited available skilled labor force,” Knight writes. “In addition, customers are calling for tighter tolerances and better finishes, parts are becoming more complex, and lot sizes are becoming smaller.”

The shortage of skilled labor for cam-actuated automatics has been a problem for years, but it is now becoming increasingly dire. Ten years ago, a study found the average age of a setup person for these types of machines was 55. Today, those workers are nearing retirement, and companies have had difficulty finding workers who want to fill those roles.

“At the same time, many of the cam automatics have fallen into less-than-prime condition,” the article notes. “Spare parts are becoming scarcer and more expensive. Plus, people who possess the knowledge to perform repairs can be rarer than the parts themselves.”

In addition to labor shortages, production turning shops are are seeing tighter tolerance requirements and more features that require secondary operations when run on traditional cam machines.

“CNC machines can hold much tighter tolerances, and can turn or bore parts down to 32 micro-inch Ra finishes or better with proper tool selections. Tolerances that would require constant adjustment on cam automatics can be held with minimal human interference on CNC screw machines.”