Greg Knight has spent 37 years working in the production turning industry. He began in 1970, deburring and washing parts at his parents’ shop, J&M Screw Products, in Carroll, Ohio. Years later, he went to work for AMT Machines Systems, which designed and produced ServoCam controls for Brown & Sharpe machine tools. He subsequently started his own company, Advanced Machinery Solutions, and began importing LICO CNC Screw Machines. After years of working with Absolute Machine Tools through his own company, Greg joined our team in 2017.

Having seen technology come and go over the decades, there’s no better person to explain how the production turning industry has evolved, so we sat down to pick his brain for this article.

Why Did Shops Move From Cam Operated Machines to CNC Machines?

Back in the late 70’s early 80’s, salesmen would come into Greg’s shop and say, “You got to get with the modern world. CNC lathes are going to replace the screw machines, you’ve got to get with it.”

“My reply would be, ‘Here are a couple of parts I’m currently making, what kind of cycle time can you run these in?’,” Greg said. “Frequently, it was 8-10 times slower than I was running on my Acme, so I would have been losing money.”

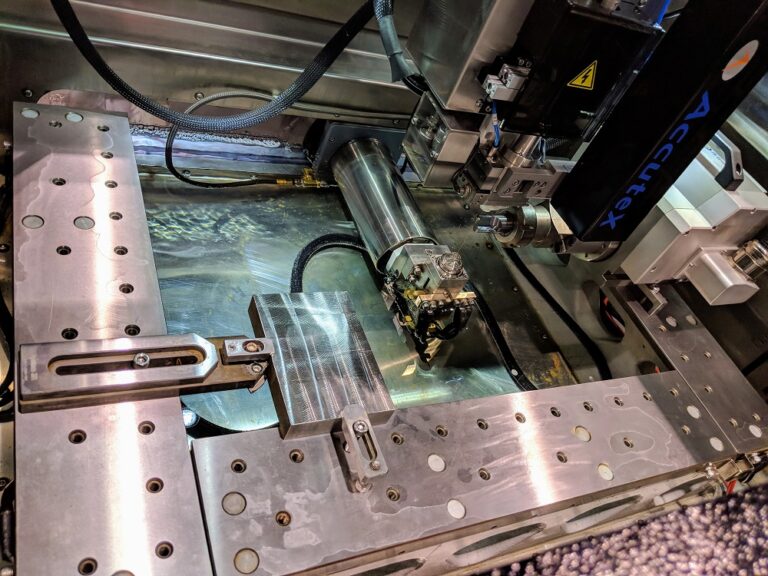

Speed on old Swiss machines was historically the problem. Back then, parts that weren’t predicated on speed issues that required high-end precision machining were often cut on an Index or Traub. Even then, those solutions came with a heavy price tag in the $500,000 – $600,000 range. Eventually, the Swiss industry came in with a lower dollar machine that was capable of making excellent quality long length-to-diameter ratios and could also perform secondary operations such as milling through the use of live tooling. While these machines still weren’t terribly fast, you could eliminate secondaries and do work where regular screw machines couldn’t. Thus, Swiss eventually replaced CAM Swiss machines.

Once the new Swiss machines with secondary operations abilities came to market, the price went from $500,000 to $200,000. Today, that has come down even less, with basic Swiss machines available for a little over $100,000.

“For that type of work, it became a great solution, and now we have an entire world-wide metal cutting industry dedicated to Swiss applications,” Greg said. “But the larger work was still a challenge to cut on a Swiss machine, so the industry came up with the non-guide bushing or air-bushing Swiss.”

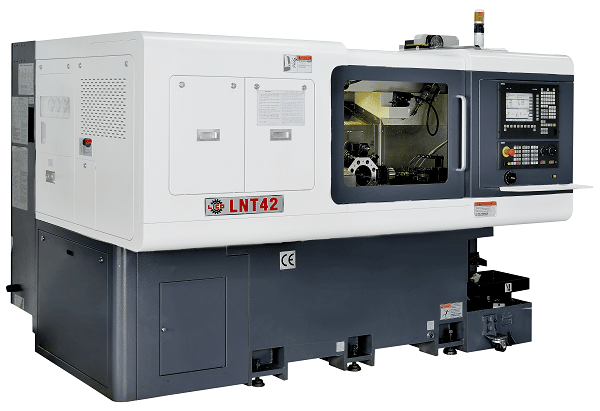

However, the fixed-head stock length-to-diameter ratios and cutting parameters still left machinists limited in what they could cut. So Taiwan-based OEM LICO came up with a solution, creating a fixed-headstock CNC machine with multiple slides.

How Are LICO Multi-Spindle Machines Different?

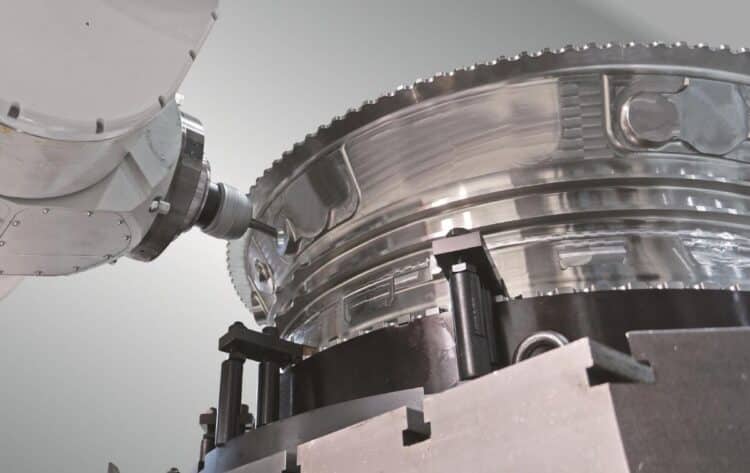

LICO machines originally began making similar machines to the Traub CAM machines when they entered the world of CNC. However, the founders didn’t want to make another CNC like everyone else in the industry was doing, they wanted to be different. So they took the technology they had created in their engineering design and expanded upon it. LICO had exclusivity on the dovetail and gibs slide (multiple overlapping slides) design and decided to package it into a new type of CNC machine. LICO machines are a true marriage of screw machine speed and CNC lathe quality and versatility.

How Does Screw Machine Speed Compare to a LICO Design?

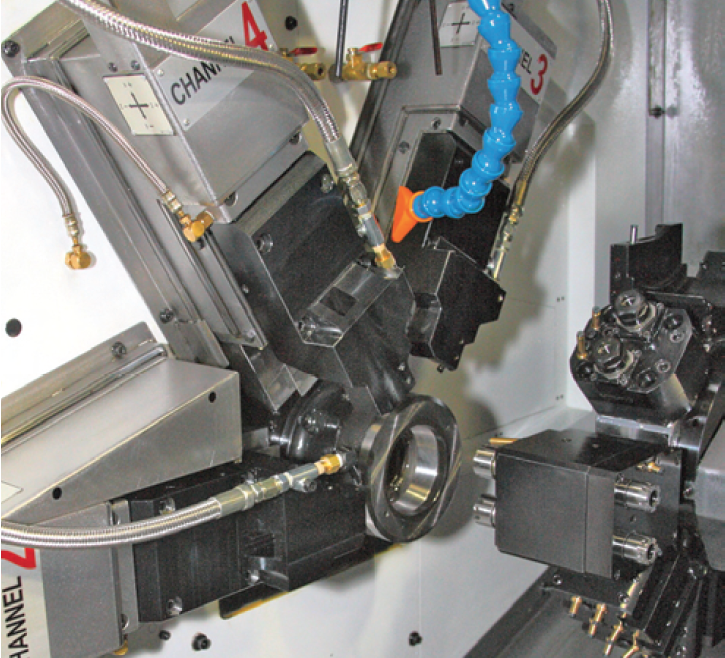

Parts that have 0-15 second cycle times are not typically as fast with a LICO. Cycle times that are 15-30 seconds are sometimes just as fast as an Acme or Brown & Sharpe. However, LICO is definitely the fastest when it comes to any part that has a 30-second or more cycle time.

“We have had reports from a few customers that tell us they have compared parts with cycle times at 0-15 seconds, and some ran faster on the LICO,” Greg said. “So it boils down to part design and set up. That’s why a time study on the part is so very important. Absolute Machine Tools has Swiss lathes, mill/turn centers, and multi-slide CNC machines. We don’t favor one over the other, we favor the most cost-effective engineered solution because it gives the end user the best value.”

Increasing Throughput, Reducing Manpower

A customer with multiple LICO multi-slide CNC machines had a particular part that was running 8.5 seconds on their Acme screw machines. Absolute performed a time study, set the machine up in our showroom, and ran that same part.

The customer had been utilizing one operator per Acme machine, hand-deburring each part, and washing and packing them for shipment. The operators were also having to load the machines with material so frequently that it was resulting in spindle utilization time just under 50%. Today, those 1.5 operators are now tending 5 LICO machines. Quantifying a savings of 3.5 operators and a 200-300% throughput rate has afforded the customer the ability to justify additional LICO machines.

“Throughput is putting good parts in the pan at the end of the day,” Greg said. “It doesn’t do a shop any good to run parts it can’t sell. The ability to combine CNC quality, multiple cuts simultaneously in material, and dropping parts totally complete greatly benefits and their ROI.”

Why Not Use a Tumbler to Debur?

Tumblers work as well, especially when deburring the OD of a part. However, the previously mentioned customer’s parts, when run on the Acme, needed to debur the ID. Even if you use small media in the tumbler to do this, it’s not as effective, and sometimes the small media gets stuck in the parts, or rolls the bur to the end of the ID. So being able to cut the ID without leaving any burrs or marks is the best solution.

What Is the Status of Brown & Sharpe and Acme Today?

Acme no longer produces new screw machines, so to get an Acme serviced or rebuilt, a shop has to utilize the services of a company like Champion Screw Machine Engineering, which specializes in Acme rebuilds and custom replacement parts. Also, Bourn & Koch in Rockford, Illinois, bought all the rights to Acme, Cone, and New Britain and owns all the repair parts data and drawings. While spare parts are available, they are not cheap, and there may be extremely long lead times if it is something not commonly kept on the shelf. Lester Detterbeck Enterprises, in Iron River, Michigan, owns the rights to Brown & Sharpe.

Unfortunately, most production screw machining houses don’t have operators that know how to repair these older screw machines. In the past, every shop had a service technician or a team of maintenance personnel that could take those machines apart, install and adjust a new spindle bearing correctly without having to read the manual. Today, just keeping these machine brands maintained has become an issue. Although there are people and companies who can, that is getting more and more infrequent. Most of those skilled, seasoned technicians that made their living repairing screw machines are now in their 60s or older, so this is a serious dilemma that will only get worse over time.

Why Not Consider a Hydromat-style Cnc Machine?

Hydromat machines are best used for parts that are under ½”. They are good machines but not inexpensive. However, if running lights out or 3 shifts, the more complex the work gets, the better chance of that making economic sense.

“This is when a time study makes a lot of sense,” Greg said. ”There are shops that have taken very inexpensive Swiss machines and moved some of their 00 work to them.”

Why Do Some Shops Hold on to These Older Screw Machines?

As very small simple parts were getting difficult to run economically here in North America, much of that piecework went overseas. Some shops, especially those that have been around for a very long time, knew that eventually the tide would turn. They also may still have some people that can run those machines, so it’s not a bad strategy if a shop can keep both the machine and operator in place. Also, there are still people out there that are training young people today to run these machines. Absolute Machine Tools has some customers that have created their own in-house programs to teach these skills; however, this is also becoming less common.

“One of the problems with training young machinists to run these machines is that the generations are not the same as they used to be,” Greg said. “Young people don’t stay with companies until they retire anymore. So, the amount of time and energy it takes to grow a new machinist to run these older screw machines doesn’t make sense like it used to. Many of today’s youth are always on the hunt for greener pastures.”

What Drives Shops to Find an Alternative Solution to Continuing to Use Older Screw Machines?

In our experience there are 3 main factors that prompt a shop to start looking for alternatives:

Running Tough Materials and Complex Parts on CNC Machines

Newer CNC machines are better in tough materials such as stainless, alloys, and various grades of titanium. Running tough material in newer CNC machines is economically viable because you can:

Also, the more complex the part, the better a newer CNC production turning machine is as well. Making complex parts on older screw machines was a long tedious process.

“Today, it’s all in the tooling and programming,” Greg said. “It’s not that the older machines can’t compete on the 12L, brasses and aluminums, but the tougher materials typically have longer cycle times and often need secondary operations. There is a giant economic justification for dropping a part complete.”

Calculate ROI on a New CNC Machine

Being able to perform an ROI for a customer is key in making the argument to buy a new CNC machine from Absolute. Over the years, our production turning applications engineering team has developed in-depth spreadsheets.

First, we calculate the cost of running the current job on the customer’s machine using their hours and dollars. Then, we calculate the cost of running the part in one, two, or even three operations — however many operations it currently takes them to complete the part. We’ll calculate spindle utilization time as well. Next we use this information to calculate the same on our production turning products in a one-and-done scenario. That way a customer can clearly see in black and white, using data they supplied, how our machine and process can return a healthy ROI.

Once we present the true numbers, the customer has the opportunity to act upon it or not. Our job is to educate customers about the different solutions. If the current solution doesn’t pencil out, we can always go back and look at a different type of machine.

Ready to Upgrade Your Shop’s Performance and Profits?

At Absolute Machine Tools, our goal is always a satisfied customer who outperforms everybody else. If you’re ready to take your business to the next level, contact us today at sales@absolutemachine.com to get started.