Greg Knight, Vice President of Sales, Production Turning Products, on “Speaking of Precision Podcast: Monday With Miles”

Listen as Greg Knight, Vice President of Sales, Production Turning Products at Absolute Machine Tools, discusses the time in manufacturing where the era of cam-operated machines hit their height and began to evolve more towards the use of CNC controlled machines, along with his experience with ServoCam CNC upgrades.

Greg explains why it is important for those running cam machines, such as Brown & Sharpes and multi-spindle machines, to move towards CNC machining. Greg discusses how cam machines make it more difficult for manufacturers to make products that consumers want due to closer tolerances, better surface finishes, and reduced lot sizes, just to name a few. Another important factor is that technology is always changing, so it is important for shops to embrace new technologies that CNC machines offer.

Today’s machinists need to be valued for more than just moving parts around the shop or chucking parts in a machine. The precision production machining industry is experiencing limited labor resources. The youth of today take great pride in learning, understanding, and operating the latest technology. A study by the Precision Machined Products Association (PMPA) 10 years ago showed that the average set-up person in a multi-spindle shop was 55 years old. Today that would make them 65 years old and most likely looking to retire. Who is going to take their place on the older cam machines?

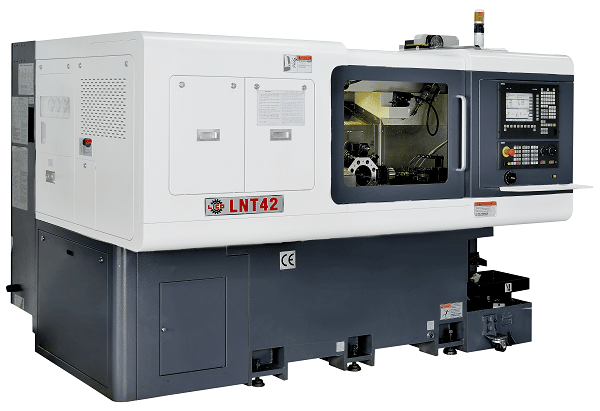

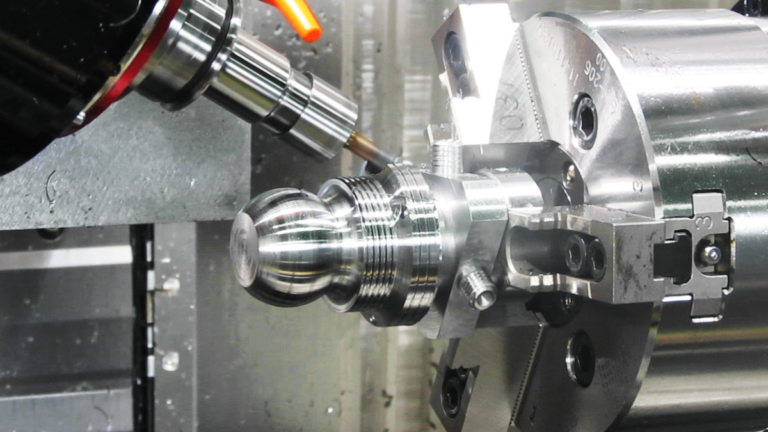

The younger generations want to run cleaner and safer machines, and not stand in oil all day long. Greg explains some of the largest advantages moving from a cam operated machine, again such as a Browne & Sharp, to a CNC machine is the reduction in cycle time, decrease in set-up time, and not having to change-out or wait on cams. Benefits with a CNC that machinists cannot easily achieve on a cam machine are cross tapping, backworking (secondary) operations that were typically done by hand, and run off-shift or lights-out utilizing a bar feeder or bar loader. With CNC machines, such as a LICO, Greg has found that when it comes to cycle times consisting of 10 seconds or less, a cam machine is typically faster than a CNC. For cycle times between 10 and 20 seconds, a time study would be necessary to prove which type of machine has the best results. However, CNC machines can typically beat most 20-30 second cycle times on a cam machine, again a time-study should be conducted, and for anything over 30 seconds, the CNC wins. Another area where CNC machines have more benefit is when compared to machines that must be rebuilt or retrofitted. Retrofitting, in many cases, is no longer a feasible solution, and rebuilding can be as expensive as a new machine; so investing in new technology becomes increasingly attractive.

Greg Knight ends his podcast with a question for those manufacturers still using cam-operated machines:

“Think seriously about what you are going to do and how you are going to handle your production processes over the next 5-10 years. Everything that you have seen change in manufacturing technology as it pertains to machinery over the past 5-10 years continued to move faster and faster. How are you going to handle your future over the next 5-10 years if you are not currently investing in updated equipment?”

This is definitely something for every job shop to consider.

For questions or discussions with Greg Knight, please email him at gknight@absolutemachine.com. Thank you for listening to Greg Knight’s PMPA podcast on the evolution of cam operated machines to CNC controlled.