Some of the technical terms used around a job shop can be confusing for those new to the industry. Check out this A-Z glossary for definitions of common CNC terminology!

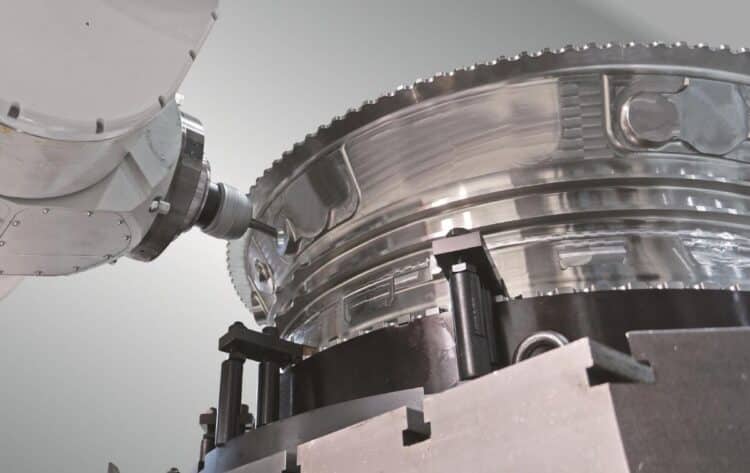

Automatic Grinding Center

A CNC machining center used to grind and sharpen tools, inserts, etc.

Automatic Tool Changer

Also known as ATC, an automatic tool changer system automatically changes the tools in a CNC machining center to fit whatever task is needed to process a product, all without the need for human operator interaction.

Axis

In CNC machining, axis refers to a plane of motion. Most CNC units work using three axes: the x-axis, the y-axis and the z-axis.

Box Tool

A box tool is a tool holder that partially surrounds a work piece in an automatic lathe or screw machine, supporting it against the pressure of the cutting tool.

Computer Aided Design

Commonly known as CAD. CAD programs allow users to digitally design parts that are to be milled, 3D printed or rendered.

Computer Aided Machining

Also known as CAM, this is the software used to control machine tools during the manufacturing of work pieces.

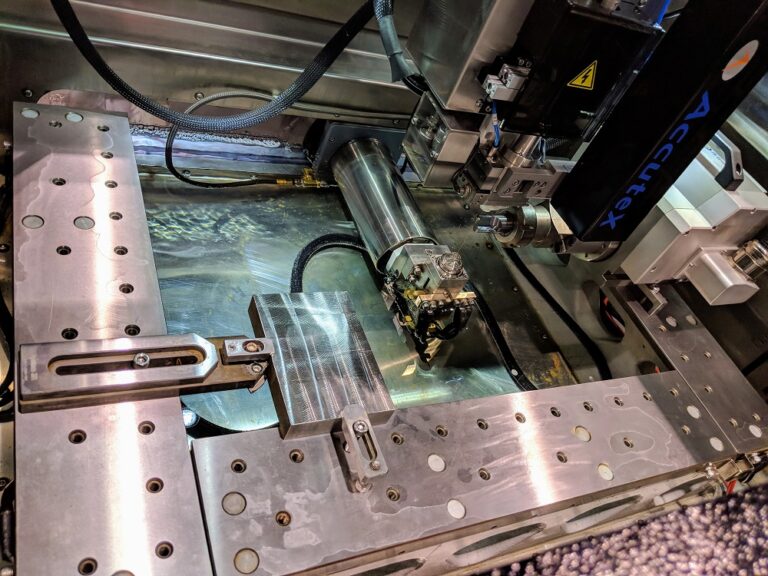

CNC Machining

CNC (Computer Numerical Control) machining uses computers to control and monitor the movements of a machine tool during the manufacturing process.

Depth of Cut

Depth of Cut denotes how much material is being removed from a work piece with each pass of the tool.

Digitizer

Scans and maps the surface of a real object, producing a 3D computer model for CAD/CAM programs.

Edge Finder

A device used to find the exact edge of a workpiece along the x or y axis.

End Mill/Endmill

Cutters used in milling machines. Types of End Mills include standard, ball nose and double ended.

Feed Rate

Refers to the speed at which a cutter can advance against a workpiece.

G-Code

G-code is a term applied to the coding language used to program and instruct a CNC machine.

Hardness

A material’s resistance to deformation or scratching by mechanical indentation or abrasion.

Horizontal Machining Center

A horizontal machining center is used for milling operations that require a horizontal spindle.

Horizontal Turning Center

A machining center used for turning operations that require a horizontal spindle.

Inserts

Inserts are cutting tips made of carbide, diamond, ceramic, or other materials, which can be easily inserted onto a cutting tool so you don’t have to remove and replace the entire tool when a tip becomes dull.

Jig

In manual machining, a jig is used to hold the workpiece and also to guide the tool.

Live Tooling

Axial or radial driven tools held in the turret of a lathe and used to perform secondary operations such as drilling or tapping.

Machining Center

A CNC milling and drilling machine that has an automatic tool changer making it capable of performing multiple operations.

Milling

CNC milling is a process that employs rotating, multi-point cutting tools to remove material from a workpiece.

NEMA Enclosures

NEMA is the National Electronic Manufacturers Association, the organization that sets the standards for the enclosures housing CNC electronics.

Offsets

Offsets are used by a CNC controller to tell a machine where a part is.

Pallet Changer

A system that allows one or more workpieces to be loaded onto pallets, which are automatically cycled through a CNC machine.

Quill

Common on manual milling machines and drill presses, the quill is a spindle feature that raises and lowers the spindle cartridge using a rack and pinion without moving the entire head.

Recutting

Recutting is what happens when chips are not removed fast enough and the cutting tool hits them again. Recutting can result in a bad surface finish or excessive tool wear.

Resolution

Resolution describes the accuracy at which a CNC machine or component can distinguish position.

Screw Machine

A screw machine is a lathe that creates parts from a continuously fed bar stock.

Setup

Preparing a CNC machine to perform a job.

Thread Mill

Cutters used in CNC milling machines to produce internal and external threads in a workpiece.

Tool Changer/Toolchanger

The component of a CNC machining center that stores and automatically switches between multiple tools.

Turning Center

Also known as a lathe, a machining center that spins a workpiece in order to cut it.

Undercut

A: A type of recessed surface inside diameter of a part that is inaccessible using a straight tool.

B: In milling, when a cutter has to reach under a shelf, undercut refers to a surface that is not visible when the part is viewed from the spindle.

Vertical Machining Center

A vertical machining center is used for operations that require a vertical spindle.

Vertical Turning Center

A vertical machining center is used for turning operations that require a vertical spindle.

Work Envelope

In CNC machining, the area a cutter can reach.

Work Hardening

A workpiece tends to become harder as it is machined.

X-Axis

The left/right horizontal axis.

Y-Axis

Up/down vertical axis, at right angles to the X-axis.

Z-Axis

Representing depth, perpendicular to both the X and Y axis.

Absolute Machine Tools Has the Tools You Need to Get the Job Done

We hope this CNC terminology glossary helps answer some of your questions. Didn’t see a term listed? Let us know!

Absolute Machine Tools is dedicated to providing the most innovative and reliable CNC machining products available today. If you’re looking to expand your CNC machining operations, or need a special tool for a special job, we’re the people to call. We have a large inventory of products designed for a wide variety of CNC machining applications and solutions. Contact Absolute Machine Tools to find out how we can help you get the job done.