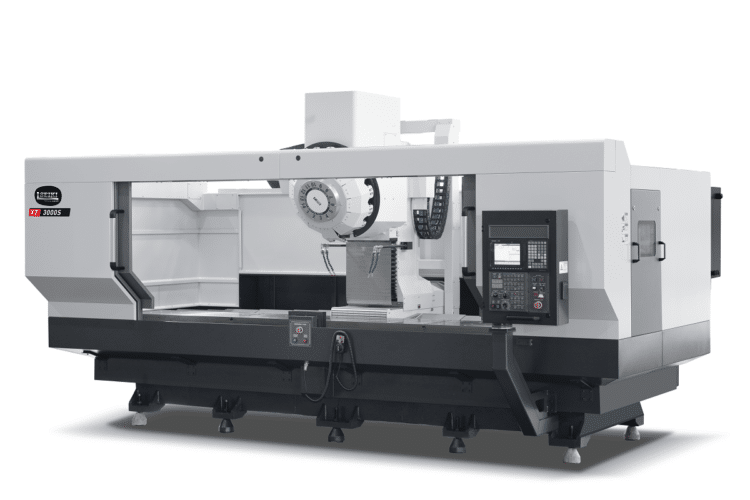

Seiki XT Series – Long Table Machining Centers

Single Spindle 6 Meter X Travel Linear Motor Milling and Tapping Center

The XT-6000S is the fastest CNC long travel milling and tapping center in its class and is also well suited to high volume machining as well high speed 3D machining. This machine will exceed the demands of any manufacturer with high volume, high precision machining needs. The machine is a fixed table / 3 axis moving column type design. The moving column design saves valuable floor space. This machine has excellent ergonomics with the chip exit in the rear of the machine and the sliding door design, the table is within easy reach. The operators panel can travel nearly the full length of the machine for ease of use.

It features a fabricated steel base with Meehanite cast iron column and table assembly and rigid roller type linear slideways for rigidity and fast, precise movement. The X axis features a linear motor with scale feedback system for fast (1181”/min) rapid travel. 32mm (1.26”) diameter YZ axis ballscrews are class 3 with a double nut pre-loaded design allowing a standard rapid traverse rate of 1969 inches per minute Z and 1890 inches per minute in Y with industry leading acceleration of 1.0G in the Z axis. The ABS (Absolute Pulse Coder) servo system does not require zero return. The machine can be started anytime from any position, saving non-productive time. A standard bed flushing system pushes chips to the rear of the machine. The optional caterpillar type chip conveyor provides efficient chip removal.

The XT-6000S is standard with a 14 tool servo turret type ATC. The turret style servo automatic tool changer provides fast, reliable tool selection. Complete tool change time is only 1.4 seconds tool to tool and 2.2 seconds chip to chip.

The standard spindle is a 7.4HP 30 min. / 5HP continuous, 15,000 RPM direct drive spindle that provides rigid tap speeds up to 6000 RPM. A spindle chiller is standard. The BBT-30 (Big Plus dual contact) taper is standard for rigid milling. Coolant through the spindle preparation is also standard (pump system optional). 24,000 RPM high speed and 12,000 RPM high torque spindles are optionally available.

The Mitsubishi M80A control is standard and is suitable for a wide range of applications from production to high speed machining applications. The M80A control features a 10.4” touch screen with intuitive smart phone type operation. A dedicated CNC CPU provides phenomenal processing speeds. An all new high response servo system with 1,000,000 pulse encoders is provided for state-of-the-art speed and accuracy. The Mitsubishi control comes with an industry leading 3 year parts and labor warranty! The Fanuc OiM-F Plus control with 10.4” LCD and 2 year warranty is also available.

Specifications

| Item / Model |

XT-6000S

Request a Quote

|

XT-6000S

Request a Quote

|

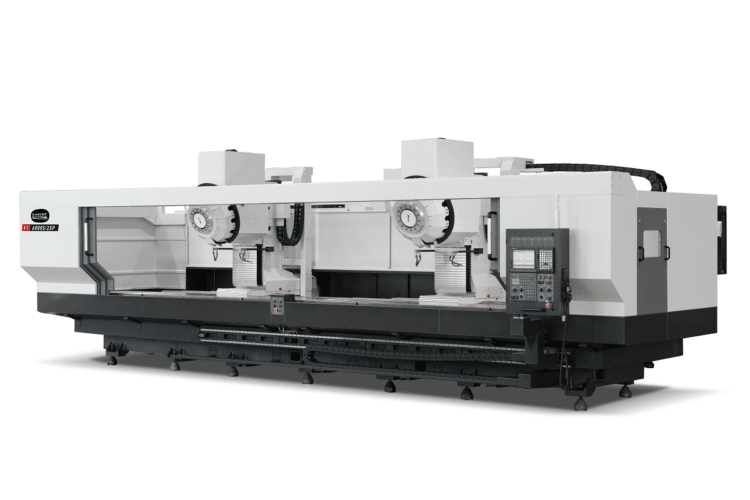

XT-6000S-2SP

Request a Quote

|

XT-6000S-2SP

Request a Quote

|

|---|---|---|---|---|

|

Turret Type (Standard) |

Arm Type (Optional) |

Turret Type (Standard) |

Arm Type (Optional) |

|

|

Travels |

||||

|

X-Axis Travel |

236″ |

236″ |

118″ x 2 (Each Spindle) |

118″ x 2 (Each Spindle) |

|

Y-Axis Travel |

16.5″ |

16.5″ |

16.5″ |

16.5″ |

|

Z-Axis Travel |

13.8″ |

28.7″ |

13.8″ |

|

|

Table to Spindle |

9.8″ min. / 23.6″ max. |

9.8″ min. / 28.7″ max. |

9.8″ min. / 23.6″ max. |

|

|

Spindle Center to Column |

19.05 |

19.05 |

||

|

Automatic Tool Changer |

||||

|

Number of Tools |

14 |

14 Each |

||

|

Tool Selection |

Bi-Directional Fixed |

Bi-Directional Fixed |

||

|

Tool Change Time |

1.4 Sec. Tool-to-Tool |

1.4 Sec. Tool-to-Tool |

||

|

Chip to Chip Time |

2.2 Sec. Chip-to-Chip |

2.2 Sec. Chip-to-Chip |

||

|

Maximum Tool Diameter |

3.15″ |

3.15″ |

||

|

Maximum Tool Weight |

4.8 lbs. |

4.8 lbs. |

||

|

Tool Type |

BBT-30 |

BBT-30 |

BBT-30 |

BBT-30 |

|

Maximum Tool Length |

7.9″ |

7.9″ |

||

|

Spindle (Standard) |

||||

|

Spindle Motor |

7.4 HP 30 min. / 5 HP continuous |

7.4 HP 30 min. / 5 HP continuous |

7.4 HP 30 min. / 5 HP continuous |

7.4 HP 30 min. / 5 HP continuous |

|

Spindle Taper |

BBT-30 Dual Contact |

BBT-30 Dual Contact |

||

|

Spindle Drive System |

Direct Drive |

Direct Drive |

Direct Drive |

Direct Drive |

|

Spindle Speed |

0 – 24,000 RPM |

0 – 24,000 RPM |

0 – 24,000 RPM |

0 – 24,000 RPM |

|

Ballscrews & Axis Motors |

||||

|

Ballscrew Diameter X-Y-Z |

Linear Motor Y 32mm (1.26”) x 20mm, Z 32mm (1.26”) x 16mm |

Linear Motor Y 32mm (1.26”) x 20mm, Z 32mm (1.26”) x 16mm |

Linear Motor Y 32mm (1.26”) x 20mm, Z 32mm (1.26”) x 16mm |

Linear Motor Y 32mm (1.26”) x 20mm, Z 32mm (1.26”) x 16mm |

|

Ballscrew Type |

Class 3 Double Nut Pre-Loaded |

Class 3 Double Nut Pre-Loaded |

Class 3 Double Nut Pre-Loaded |

Class 3 Double Nut Pre-Loaded |

|

Ballscrew Mounting Type |

Double Anchored |

Double Anchored |

Double Anchored |

Double Anchored |

|

Servo Motor HP Y-Z |

3.0 – 3.0 |

3.0 – 3.0 |

3.0 – 3.0 |

3.0 – 3.0 |

|

Servo Motor Mounting |

Direct Coupled |

Direct Coupled |

Direct Coupled |

Direct Coupled |

|

Table |

||||

|

Table Working Surface |

259.8″ x 18.1″ |

259.8″ x 18.1″ |

259.8″ x 18.1″ |

259.8″ x 18.1″ |

|

Max. Workload on Table |

2,400 lbs. |

2,400 lbs. |

2,640 lbs. |

2,640 lbs. |

|

Table Surface |

Ground / T-Slotted / Tapped |

Ground / T-Slotted / Tapped |

Ground / T-Slotted / Tapped |

Ground / T-Slotted / Tapped |

|

Feeds |

||||

|

Rapid Traverse Rate X, Y, Z |

1,181, 1,890, 1,969 IPM |

1,181, 1,890, 1,969 IPM |

1,181, 1,890, 1,969 IPM |

1,181, 1,890, 1,969 IPM |

|

Acceleration in Z |

1.0G |

1.0G |

1.0G |

1.0G |

|

Cutting Feed Rate |

0.01 – 787 IPM |

0.01 – 787 IPM |

0.01 – 787 IPM |

0.01 – 787 IPM |

|

Positioning Accuracy |

+/- .0002″ Full Stroke |

+/- .0002″ Full Stroke |

+/- .0002″ Full Stroke |

+/- .0002″ Full Stroke |

|

Repeatability |

+/- .00015″ |

+/- .00015″ |

+/- .00015″ |

+/- .00015″ |

|

General |

||||

|

Coolant Tank Capacity |

~ 100 Gallons |

~ 100 Gallons |

~ 100 Gallons |

~ 100 Gallons |

|

Machine Weight |

34,320 lbs. |

34,320 lbs. |

34,320 lbs. |

34,320 lbs. |

|

Floor Space |

310″ x 103″ x 100″ |

310″ x 103″ x 109″ |

310″ x 103″ x 100″ |

310″ x 103″ x 109″ |

|

Power Source |

208/220 Volts, 3 Phase, 35 KVA** |

208/220 Volts, 3 Phase, 35 KVA** |

208/220 Volts, 3 Phase, 35 KVA** |

208/220 Volts, 3 Phase, 35 KVA** |

|

Air Source |

90 PSI |

90 PSI |

90 PSI |

90 PSI |

**Consult AMT or your local distributor for exact power requirements when ordering**