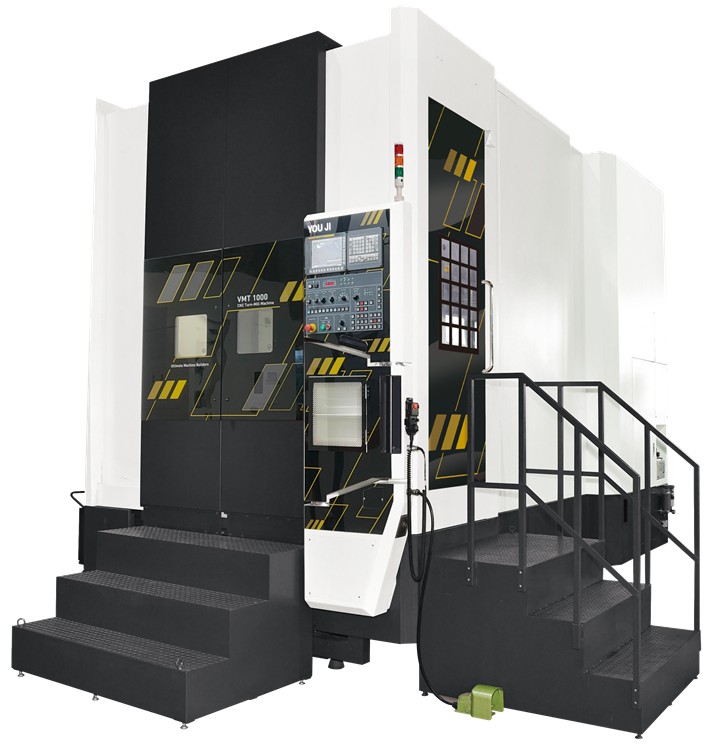

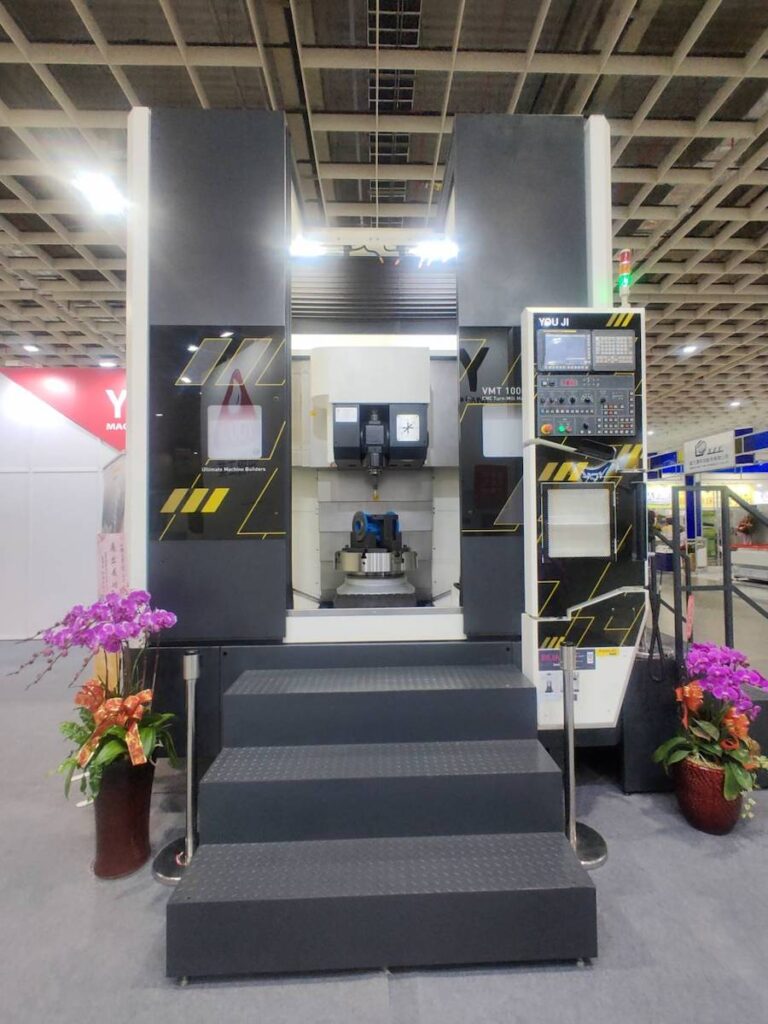

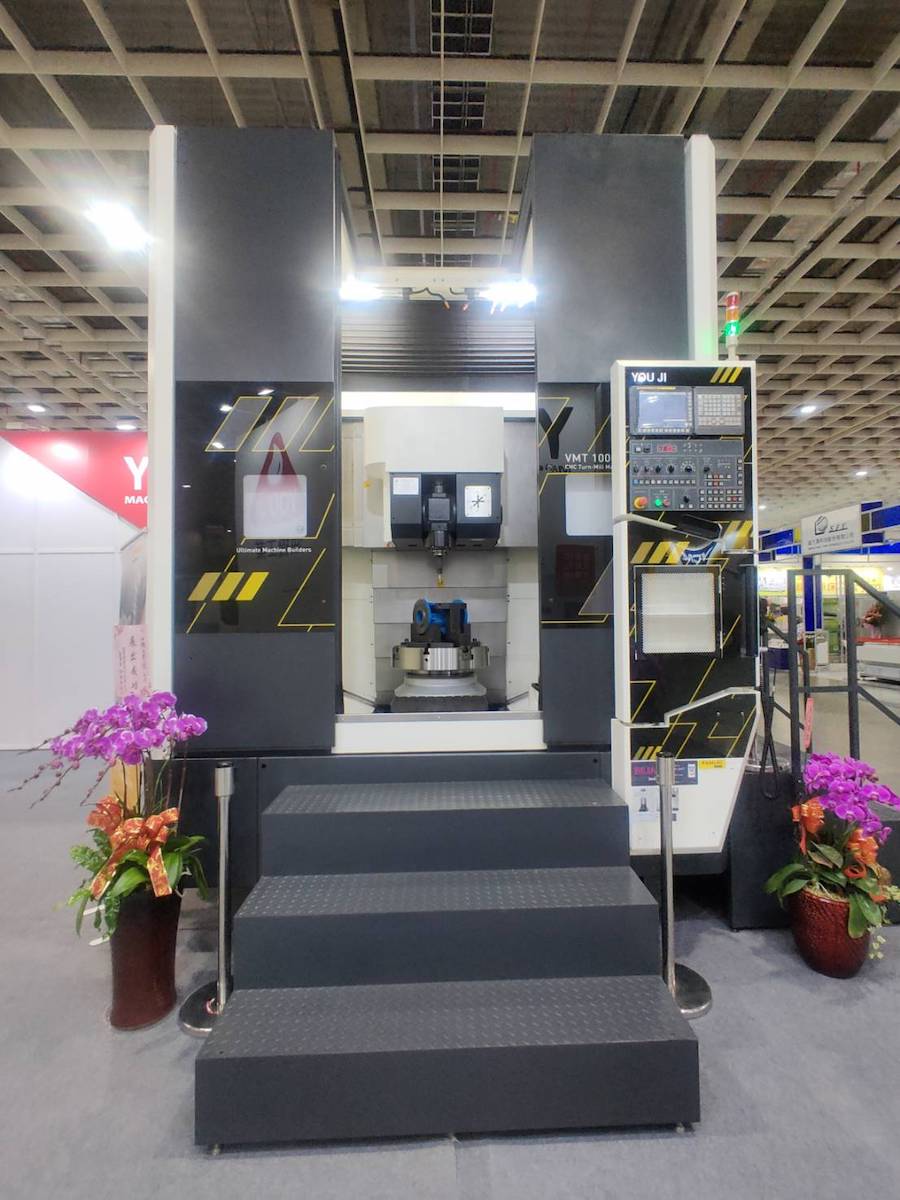

You Ji VMT Series – Vertical Mill-Turn Centers

The You Ji VMT Vertical Mill /Turn Center Series combines 3-axis 5-face machining with vertical turning capabilities. The machines provide 5-sided or 4+1 axis milling and turning of medium size workpieces, producing complete parts in a single set-up. A full C-axis allows for 4-axis simultaneous milling, making the machines ideal for aerospace and energy industry applications.

Built for stability and precision, the machine’s vertical column and base are heavily ribbed Meehanite® castings, minimizing thermal distortion and effectively dampening vibration. The X, Y, and Z axes feature fully enclosed box guideways with hand-scraped mating surfaces, Turcite-B coatings, and forced lubrication for long-lasting accuracy and smooth motion.

High-torque servo motors directly drive large 2″ diameter Class-3 precision ballscrews on all three axes, eliminating the need for belts or gears. The design incorporates a fixed turning spindle with a 3-axis moving column, enhancing operator accessibility and optimizing chip evacuation.

The B-axis milling head is equipped with a robust Hirth coupling for secure positional locking. A 90° index comes standard for vertical and horizontal milling operations, while optional 5° and 1° indexing configurations are available for increased versatility.

As with all You Ji CNC machine tools, customized models are available upon request.

Specifications

| Item / Model |

VMT-1000+Y

Request a Quote |

|---|---|

|

Capacities | |

|

Maximum Turning Diameter |

39.4″ |

|

Maximum Swing Diameter |

39.4″ |

|

Maximum Cross Travel (X-Axis) |

44.09” (-1.97” / + 42.12”) |

|

Maximum Longitudinal Travel (Z-Axis) |

44.68″ |

|

Maximum Off-Center Travel (Y-Axis) |

29.5” (+/- 14.76” from center) |

|

Distance from Milling Spindle Nose to Chuck Face (Vertical) |

37.87″ |

|

Distance of Milling Spindle Face to Chuck Centerline (Horizontal) |

33.35″ |

|

Spindle | |

|

Spindle Motor (Fanuc P Series) |

30 HP Double Wound (more torque at lover RPM than a 50HP single wound motor) |

|

Spindle Drive |

2 Speed ZF Planetary Gearbox |

|

Spindle Nose |

A2-11 |

|

Spindle RPM |

0-1500 |

|

Spindle Bearing Diameter |

7.87″ |

|

Spindle Inside Taper |

M. T. 7 |

|

Hydraulic Chuck |

24″ 3-Jaw |

|

ATC | |

|

Tool Positions |

24 (40/60 opt.) |

|

ATC Type |

Arm-Type with Tool Chain |

|

Tool Mounting |

#50 Taper |

|

Maximum Tool Diameter with Adjacent Tools |

5″ |

|

Maximum Tool Diameter without Adjacent Tools |

10″ |

|

Maximum Tool Length |

13.8″ |

|

Maximum Tool Weight |

55 lbs. |

|

Tool Change Time |

15-20 Seconds |

|

Ballscrews and Axis Motors | |

|

Z-Axis Ballscrew Diameter |

50mm (1.96″) x 16mm Pitch |

|

X-Axis Ballscrew Diameter |

50mm (1.96″) x 10mm Pitch |

|

Y-Axis Ballscrew Diameter |

50mm (1.96″) x 12mm Pitch |

|

Ballscrew Type |

Class 3 Double Nut |

|

Ballscrew Mounting Type |

Pre-loaded, Double Anchored |

|

X-Z-Y-C Servo Motor HP |

X=8HP / Z=12HP / Y=5.2HP / C=4HP |

|

C-Axis and B-Axis Milling Spindle | |

|

Milling Spindle Motor |

20 HP |

|

Spindle RPM |

3,500 |

|

Tool Shank Type |

BT-50 (CAT-50 opt.) |

|

Spindle Torque |

178 ft./lbs. at 437 RPM |

|

B-Axis Head Rotation |

0-90° (2 positions) 5° or 1° Index Opt. |

|

C-Axis Indexing |

.001° |

|

C-Axis Rapid Speed |

3.4 RPM |

|

C-Axis Positioning Accuracy |

+/- 7.5 Arc Seconds |

|

C-Axis Repeatability |

+/- 5 Arc Seconds |

|

Feeds | |

|

Rapid Traverse Rate X, Y, Z |

394, 394, 394 IPM |

|

Cutting Feed Rate |

0.01 – 157 IPM |

|

Positioning Accuracy |

+/- .0003″ Full Stroke |

|

Repeatability |

+/- .0002″ |

|

General | |

|

Coolant Tank Capacity |

100 Gallons |

|

Coolant Pump Motor |

4 HP |

|

Machine Weight |

48,400 lbs. |

|

Floor Space |

220″ x 228″ x 160″ |

|

Machine Power Source |

208/220V, 3-Phase, 150 Amps |

|

Hydraulic Pump Motor |

7.5 HP |