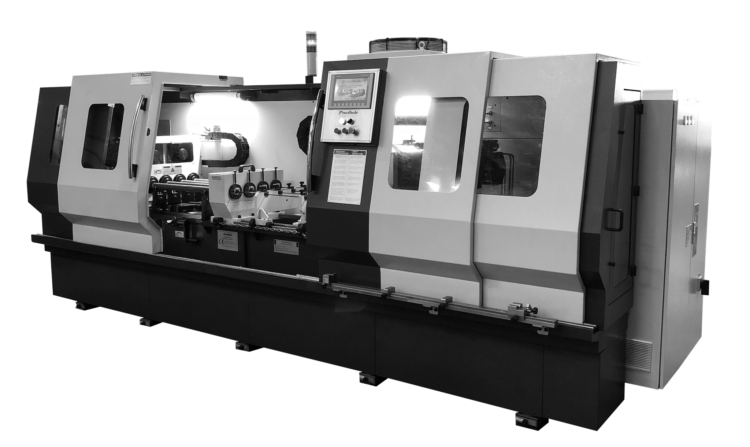

Precihole GVN-C Series – Single Axis Gun Drilling Machines with Counter Rotation

Precihole’s GVN-C Series Gun Drilling Machines with Counter Rotation offer superior hole concentricity as it relates to deep hole drilling for high precision gun barrels. These machines incorporate the latest technology available and can be customized to suit volume requirements and provide excellent straightness, surface finish and bore tolerance. Length to diameter ratios of up to 125 are possible. The Precihole GVN-C series machines are complete solutions that include features needed for continuous and repeatable performance over many years. The gun drilling operation is considered one of the most critical operations in the barrel making process. This process really decides the quality of the finished barrel. Precihole’s GVN-C series barrel machines offer the best combination of output parameters like hole straightness, surface finish and bore tolerance. Having counter rotation in the Precihole GVN-C series is effective for drilling holes of 40:1 depth to diameter ratios or more.

Machine features:

Specifications

| Item / Model |

GVN08C

Request a Quote |

GVN12C

Request a Quote |

GVN20C

Request a Quote |

GVN25C

Request a Quote |

GVN40C

Request a Quote |

|---|---|---|---|---|---|

|

Drilling Diameter Range |

0.08″ – 0.3″ |

0.12″ – 0.47″ |

0.197″-0.1″ |

0.315″ – 1″ |

0.31″ – 1.57″ |

|

Number of Spindles |

1 / 2 /4 |

1 / 2 /4 |

1 / 2 /4 |

1 / 2 |

1 / 2 /4 |

|

Max. Drilling Depth |

16″/24″/40″ |

16″/24″/40″ |

16″/24″/40″ |

16″/24″/40″ |

16″/24″/40″ |

|

Part OD Range |

0.4″ – 2″ |

0.4″ – 2″ |

.47″ – 3″ |

.47″ – 3″ |

.6″ – 4″ |

|

Part Clamping System |

Hydraulic Cone Clamping / Chuck Clamping |

Hydraulic Cone Clamping / Chuck Clamping |

Hydraulic Cone Clamping / Chuck Clamping |

Hydraulic Cone Clamping / Chuck Clamping |

Hydraulic Cone Clamping / Chuck Clamping |

|

Max. Component Weight |

67 lbs. |

67 lbs. |

111 lbs. |

111 lbs. |

155 lbs. |

|

Counter Rotation Speed (RPM) |

300 RPM |

300 RPM |

300 RPM |

140 RPM |

300 RPM |

|

Drill Feed Range |

0-40 IPM |

0-40 IPM |

0-40 IPM |

0-40 IPM |

0-40 IPM |

|

Rapid Traverse |

393 IPM |

393 IPM |

315 IPM |

315 IPM |

157 IPM |

|

Power per Spindle |

2 HP |

3 HP |

7.5 HP |

10 HP |

20 HP |

|

Spindle Speed |

2000-12000 RPM |

1200-10000 RPM |

600-6400 RPM |

600-3300 RPM |

350-3300 RPM |

|

Coolant Tank Capacity (Gallons) |

225/238/290 |

225/238/290 |

277/290/330 |

277/290/330 |

530 |

|

Max. Coolant Pressure (PSI) |

1740 |

1450 |

1160 |

870 |

870 |

The GVN12C/4-800 is capable of handling gun drilling of gun barrels for all small arms weapon calibers up to 32’’ in length. Here are some of its improved features and their benefits: