Nexturn SA(PII) 7-Axis Swiss Lathe Series

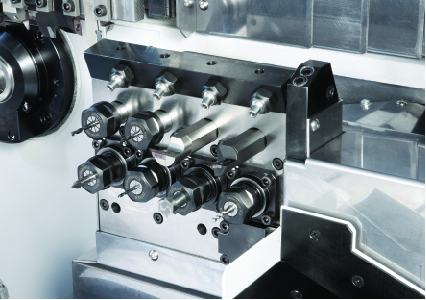

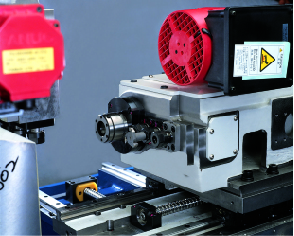

The SA(PII) is our mid-level machine available with or without rotary synchronous guide bushing. It features a total of 7 axes (Z1, X1, Y, Z2, X2, C1, and C2) and up to 23 total tools. Bar capacity is 20/26/32/38mm with 250mm (9.8”) maximum turning length in one chucking. High precision integral motor spindles on both main and sub provide excellent precision and fast cycle times.

The machine is built for rigidity, accuracy, reliability, and ease of use. The highly rigid one-piece cast iron machine bed is designed using FEM software. Powerful motors for both turning and milling deliver outstanding machining capability. The use of ultra-precision pre-tensioned ballscrews and LM guides produce high accuracy. High speed positioning of 1260”/min. reduces cycle times. A sliding operators door, as opposed to a lift up style door, provides easy access to the machining area and is drip free.

Specifications

| Item / Model |

SA-20PII

Request a Quote |

SA-32PII

Request a Quote |

SA-38PII

Request a Quote |

|---|---|---|---|

|

FREE TRACER 20 Bar Feeder |

FREE TRACER 32V Bar Feeder |

FREE TRACER 51V Bar Feeder Package | |

|

Number of Axes |

7 |

7 |

7 |

|

Number of Channels |

2 |

2 |

2 |

|

Bar Capacity (Front/Rear) |

20 mm / 20 mm |

32 mm / 32 mm |

38 mm / 38 mm |

|

Guide Bushing Type |

Synchronous |

Synchronous |

Synchronous |

|

Main Spindle |

5 HP / 10,000 RPM |

10 HP / 8,000 RPM |

10 HP / 8,000 RPM |

|

Sub Spindle |

3 HP / 8,000 RPM |

5 HP / 8,000 RPM |

5 HP / 8,000 RPM |

|

Max. Turn Length |

10″ |

10″ |

10″ |

|

Total Tools |

23 |

20 |

19 |

|

Fixed Tools (Front/Rear) |

12 / 3 |

12 / 2 |

11 / 2 |

|

Live Tools (Front/Rear) |

6 / 2 |

4 / 2 |

4 / 2 |

|

Live Tools |

3 HP / 6,000 RPM |

3 HP / 6,000 RPM |

3 HP / 6,000 RPM |

|

B Axis |

N/A |

N/A |

N/A |

|

C Axis Contouring |

Main/Sub |

Main/Sub |

Main/Sub |

|

CNC Control |

FANUC OiTF |

FANUC OiTF |

FANUC OiTF |

|

Weight |

7,260 lbs. |

7,700 lbs. |

7,920 lbs. |

FAQs

How are Swiss lathes and conventional lathes different?

The guide bushing is the key difference that separates Swiss lathes from conventional lathes. On a CNC Swiss lathe, the guide bushing holds the workpiece close to the cutting tool, which gives significantly improved support for greater precision through the entire cutting process. This results in the ability to achieve a high quality surface finish. On a conventional lathe, the workpiece is held by a chuck; when the cutting tool is machining material further away from the chuck, stability is reduced, which tends to result in a poorer surface finish quality.

Is a rotary or fixed guide bushing better?

While both have their uses, a rotary guide bushing is generally the preferred option. The rotary guide bushing acts as a slave to the material being machined, spinning along with it. If the rotary guide bushing is set properly, this keeps material from getting into the guide bushing. Because the guide bushing stays in contact with the part, the amount of marring or scratching is reduced, resulting in excellent surface finish. On the other hand, a fixed guide bushing stays static while the bar stock rotates. This tends to result in damage to the material it is holding.

How many axes does a Swiss lathe have?

The number of axes a Swiss lathe will have varies. For instance, the Nexturn SA(PII) features a total of 7 axes (Z1, X1, Y, Z2, X2, C1, and C2). Most conventional Swiss machines have anywhere from 7-9 axes.