Quicktech Robo Series – 4-Axis Mill-Turn Centers with Integrated 6-Axis Robot & B-Axis

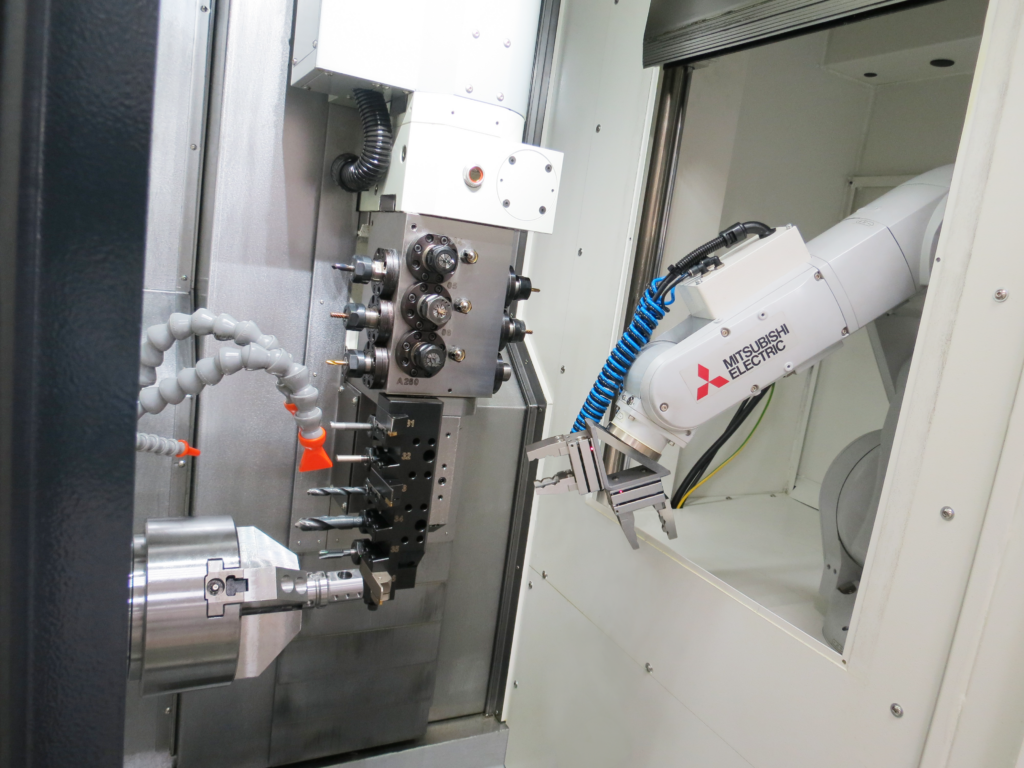

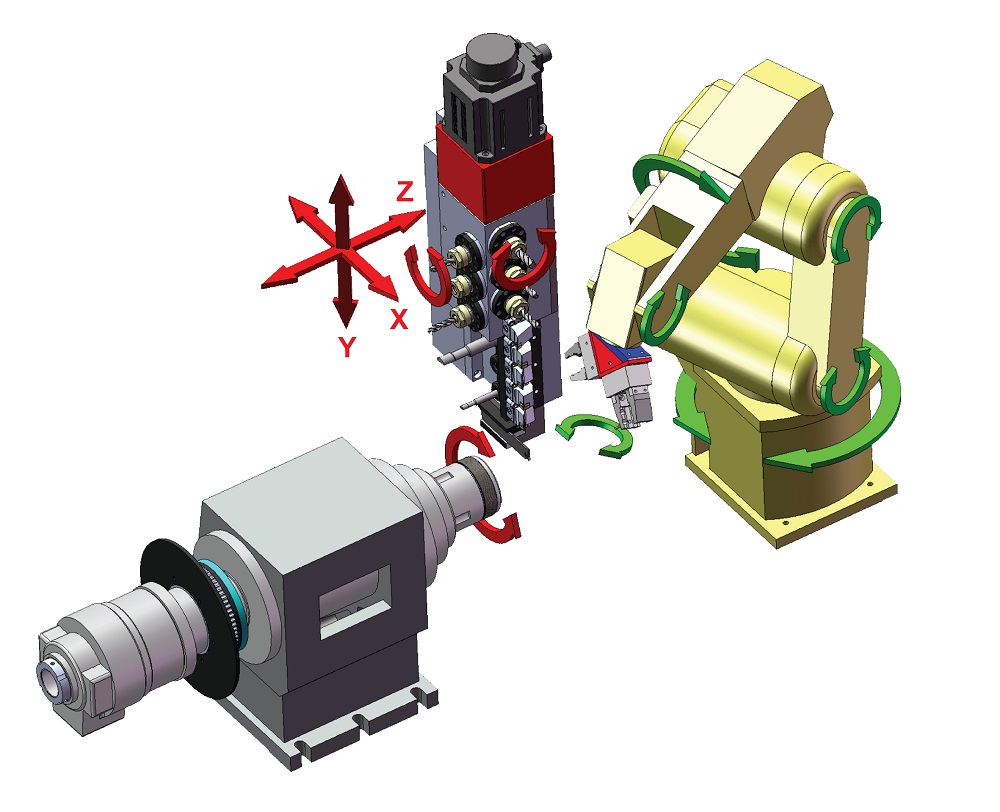

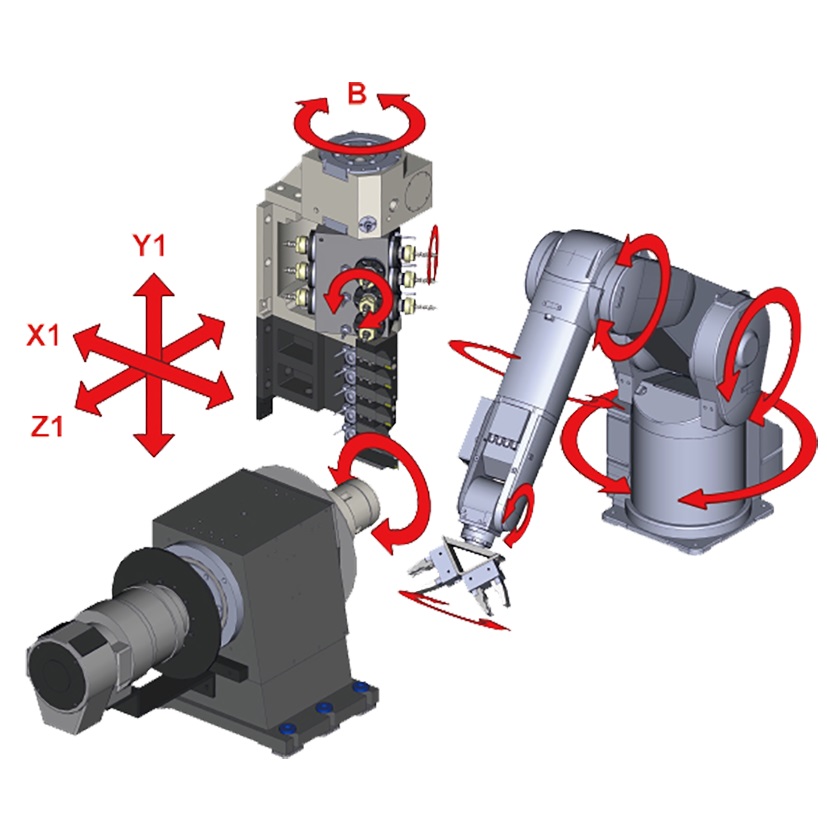

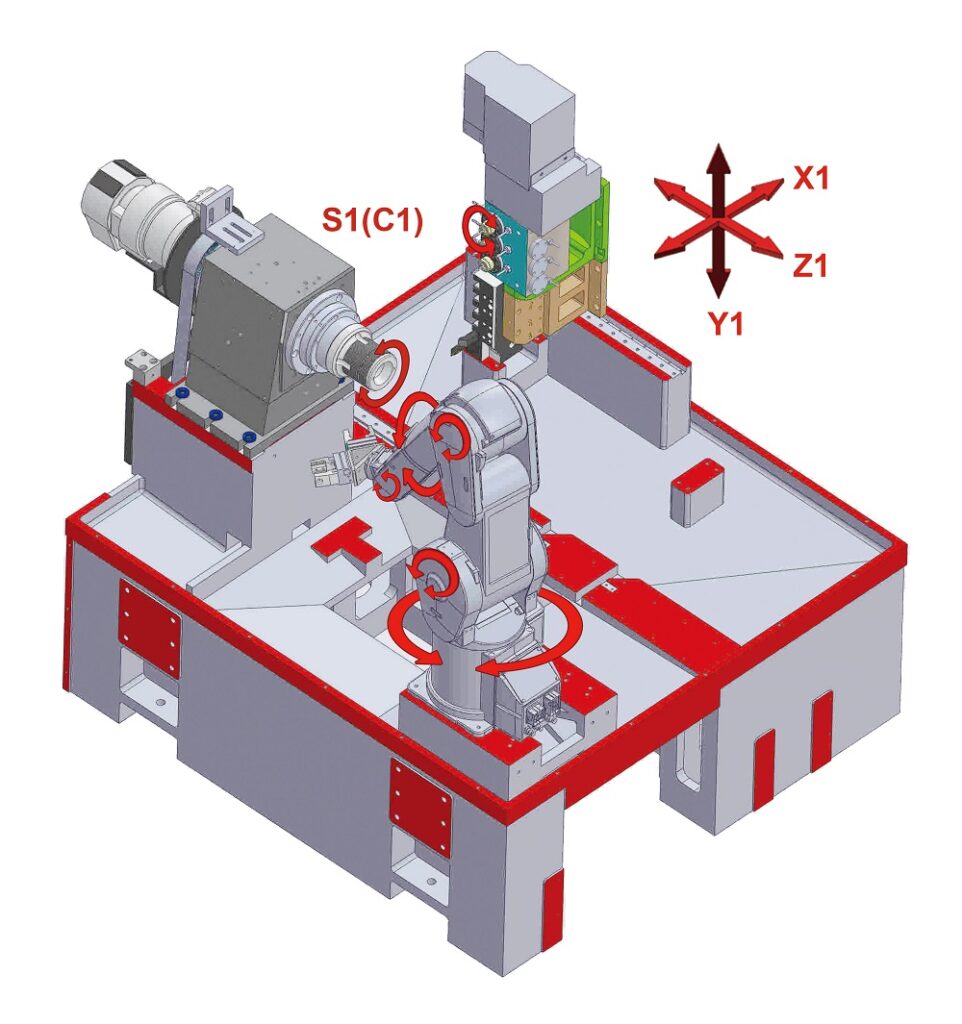

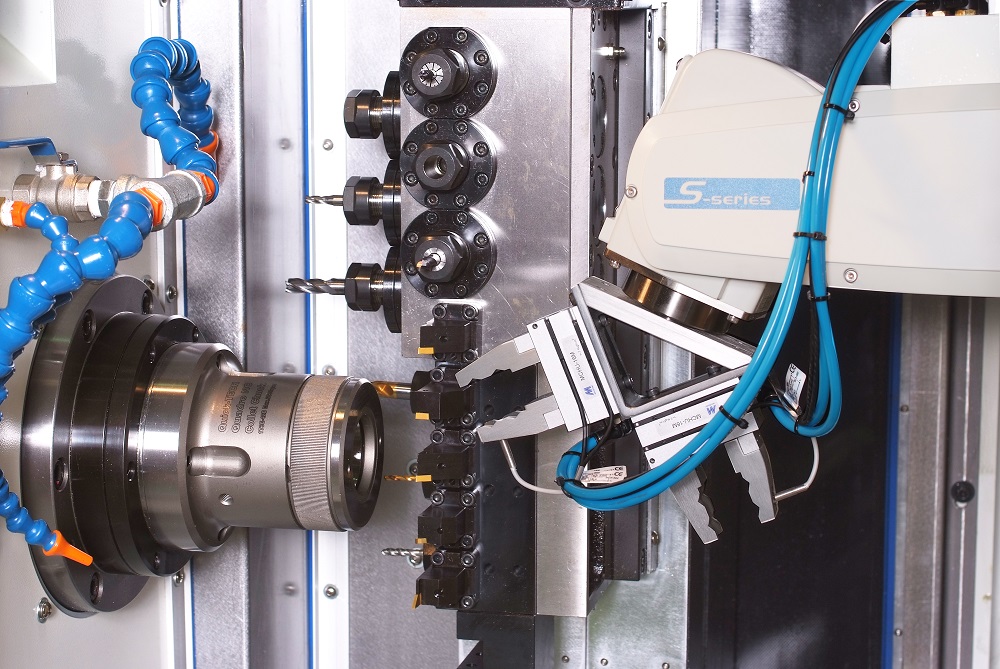

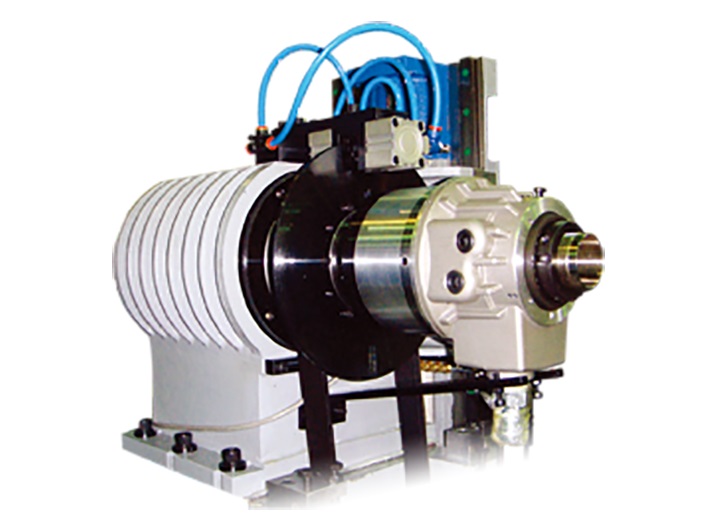

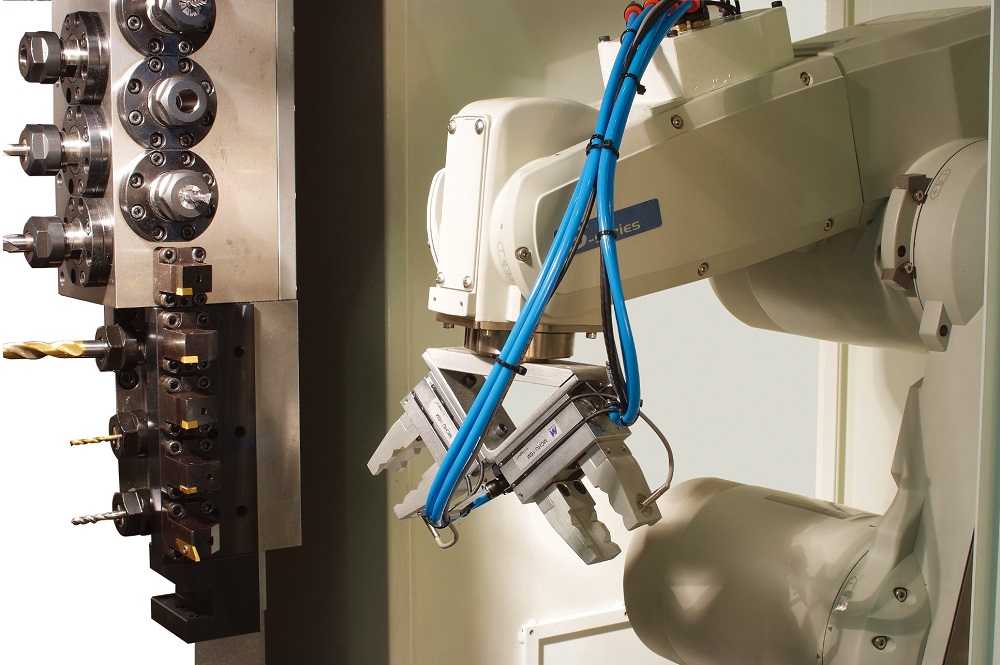

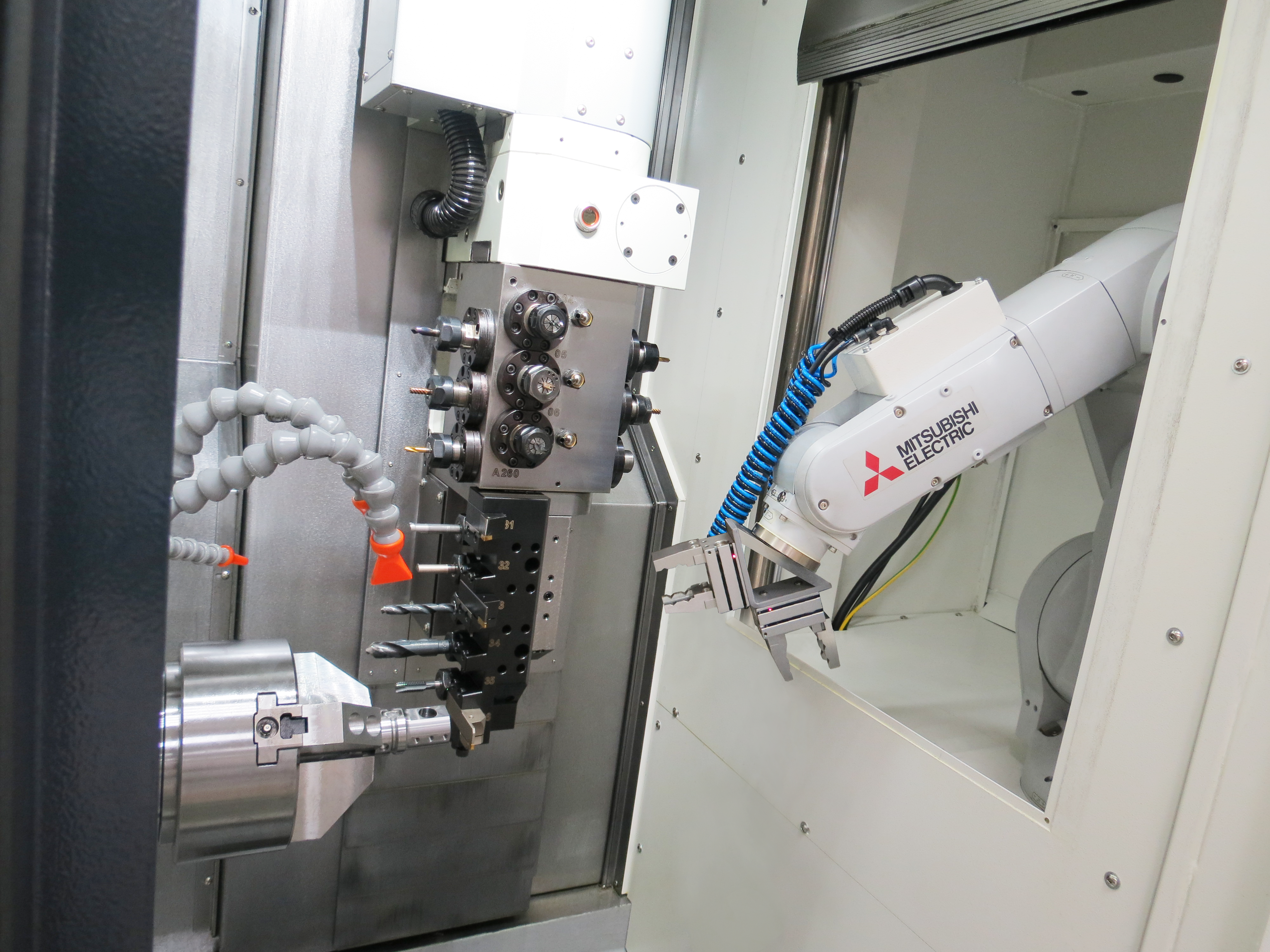

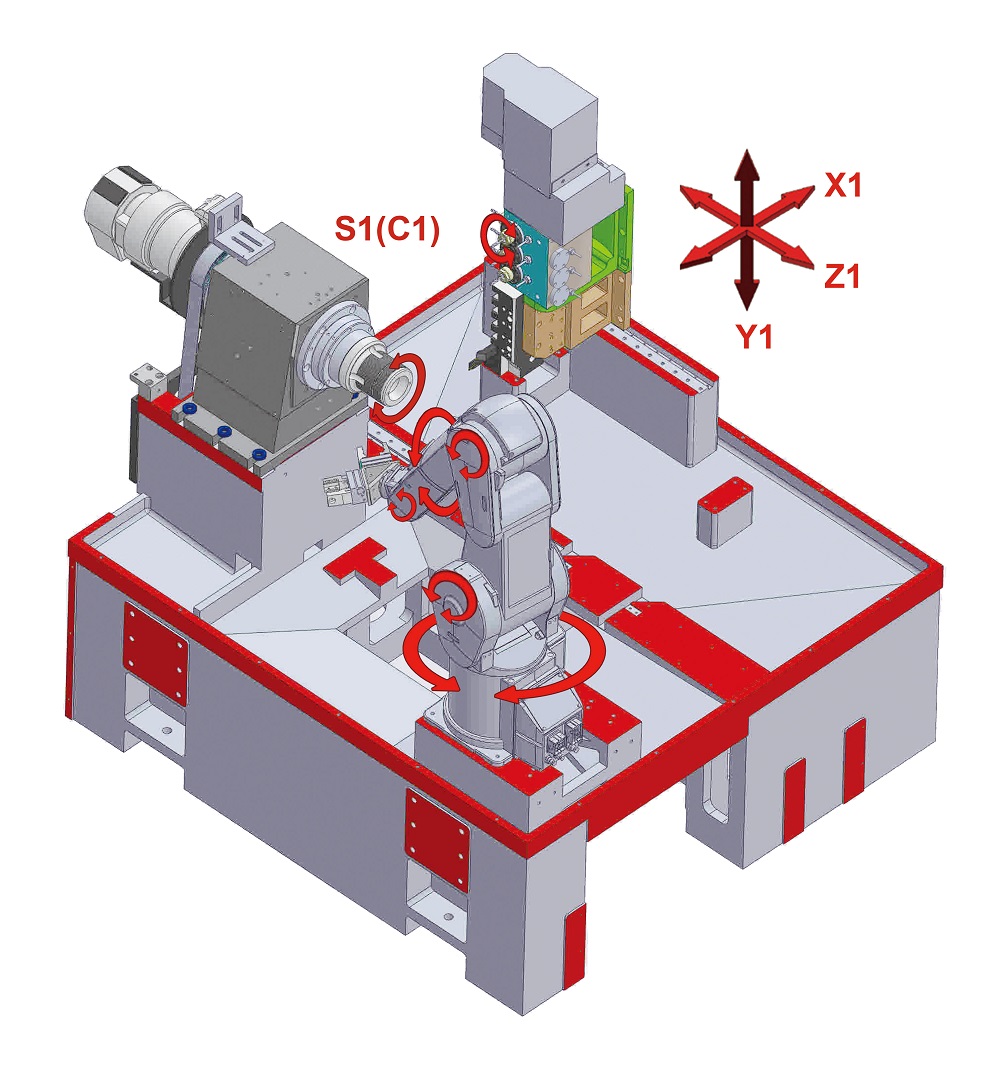

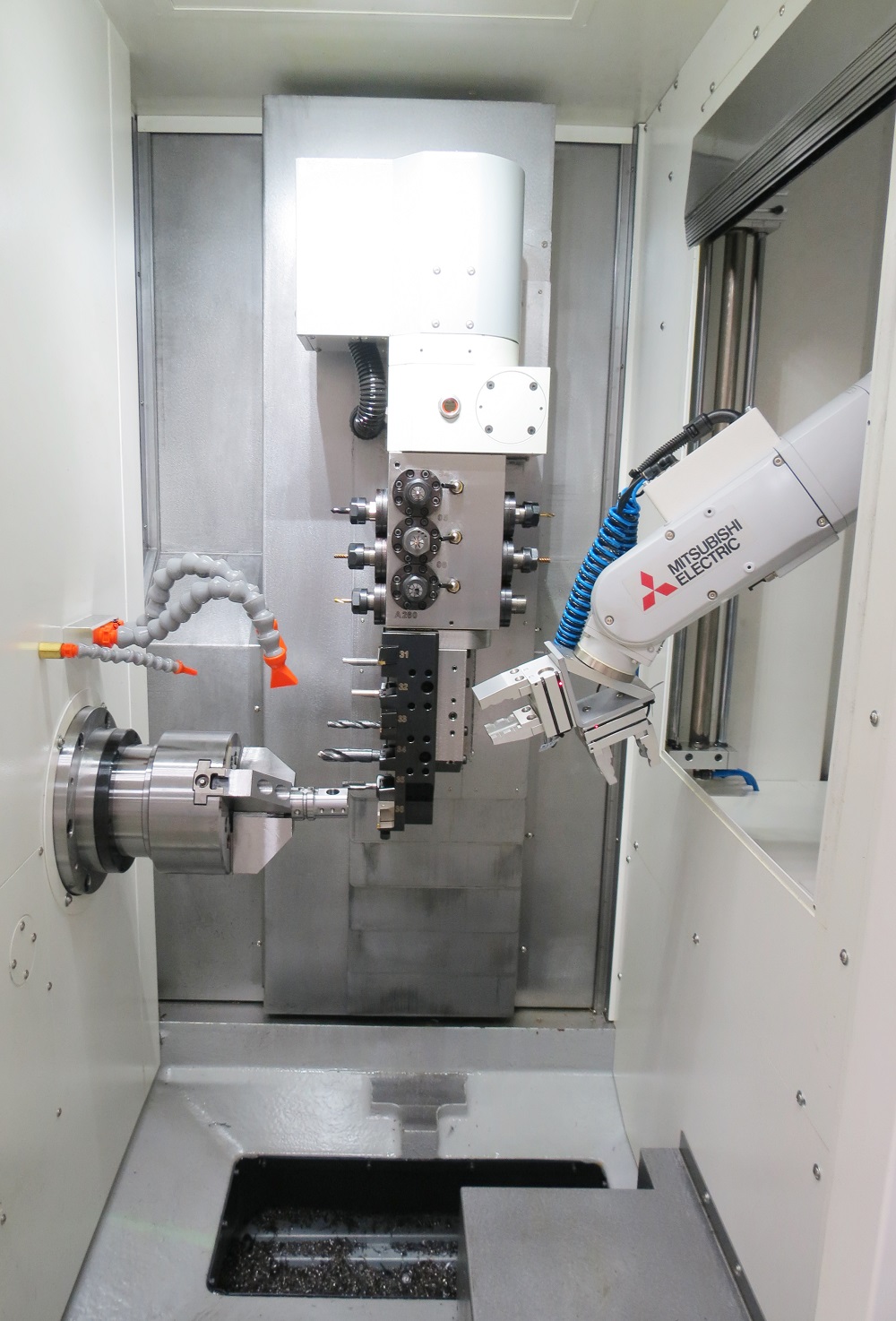

The QuickTECH Robo Series — available in i-42 Robo and i-60 Robo models — combines precision CNC mill-turn capability with a fully integrated Mitsubishi 6-axis robot for automatic part loading, unloading, and turnover. Each machine is a compact, high-performance production center cast from Meehanite iron and engineered for true lights-out CNC automation. With up to five controllable axes (optional B-axis), the Robo Series delivers high-accuracy turning and milling in one setup while dramatically reducing operator intervention.

These machines are ideal for medical, aerospace & defense, automotive, and precision component manufacturers looking to enhance productivity, overcome labor shortages, and achieve consistent, repeatable quality. The Robo Series provides machine tool automation solutions that rival integrated systems from Haas, Doosan, DMG Mori, and Mazak — but in a smaller, more cost-effective footprint.

Key Features

Specifications

| Item / Model |

i-42 ROBO

Request a Quote

|

i-60 ROBO

Request a Quote

|

|---|---|---|

|

Main Spindle Capacity | ||

|

Max Bar Working Capacity |

1.65″ |

2.36″ |

|

Max Turning Length |

9.8″ |

9.8″ |

|

Spindle Speed Range (std) |

6,000 RPM |

4,000 RPM |

|

Spindle Motor |

15 HP |

15 HP |

|

C-Axis Increment |

.001° |

.001° |

|

Travel and Feed | ||

|

Rapid Traverse Rate |

1,181″/min. |

1,181″/min. |

|

Tooling System | ||

|

Tooling Type |

Gang Tool / Servo Y-Axis / KM-25 Quick Change |

Gang Tool / Servo Y-Axis / KM-25 Quick Change |

|

Number of Turning Tools |

6 O.D. (5 + 1 Cut-Off) & 5 I.D. |

6 O.D. (5 + 1 Cut-Off) & 5 I.D. |

|

Square Shank Size |

.75″ (20mm) |

.75″ (20mm) |

|

Boring Bar Capacity |

.75″ (ER-20) |

.75″ (ER-20) |

|

B-Axis |

360° |

360° |

|

B-Axis Index Time |

.3 Seconds 90° / .6 Seconds 360° |

.3 Seconds 90° / .6 Seconds 360° |

|

Number of Live Tools |

6 (3 Axial/3 Radial) (12 opt.) |

6 (3 Axial/3 Radial) (12 opt.) |

|

Live Tool Spindle Motor |

2 HP |

2 HP |

|

Live Tool Spindle Speed |

4,000 |

4,000 |

|

Live Tool Shank |

ER-20 Collet |

ER-20 Collet |

|

Robot | ||

|

Type |

Mitsubishi S Series |

Mitsubishi S Series |

|

No. of Axes |

6 Articulated |

6 Articulated |

|

Drive System |

Mitsubishi AC Servo Motors |

Mitsubishi AC Servo Motors |

|

Position Detection Method |

Absolute Encoder |

Absolute Encoder |

|

Load Carrying Capacity (Max/Rated) |

13.2 lbs. / 11 lbs. |

13.2 lbs. / 11 lbs. |

|

Position Repeatability |

± .0008″ |

± .0008″ |

|

General | ||

|

CNC Control |

Mitsubishi M80A |

Mitsubishi M80A |

|

Machine Dimensions with Chip Conveyor |

132″ x 60″ x 77″ |

132″ x 60″ x 77″ |

|

Machine Weight |

6,050 lbs. |

6,050 lbs. |

Benefits for Metal Cutting Manufacturers and Parts Producers

The QuickTECH Robo Series transforms traditional machining into an automated production cell, combining a proven 4-axis mill-turn design with a built-in robot for seamless part handling.

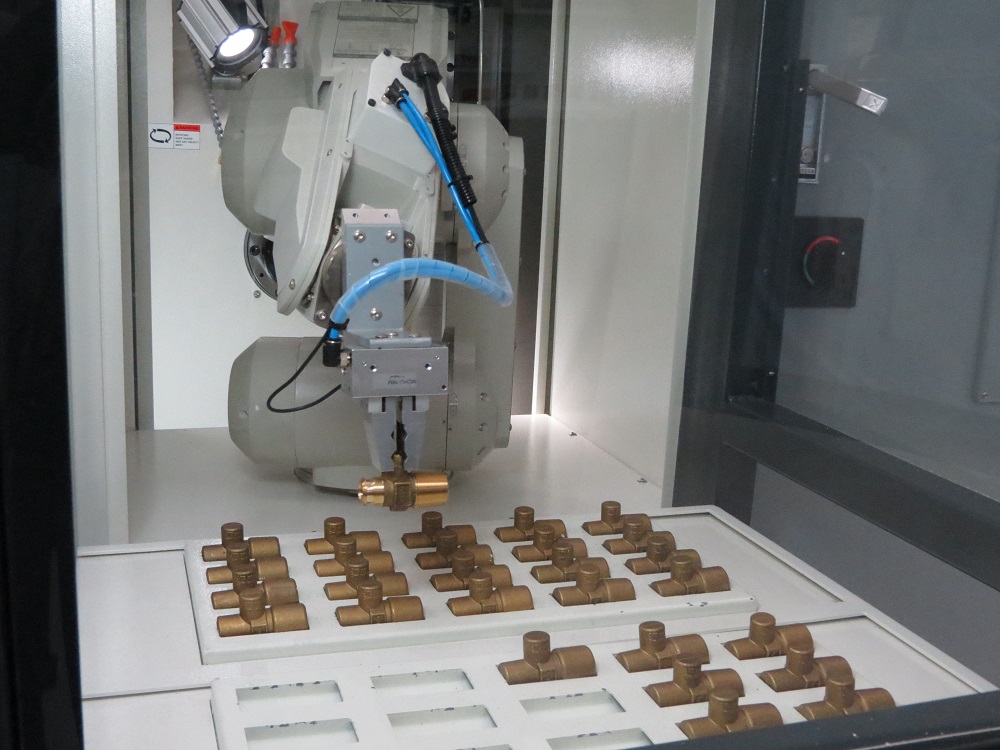

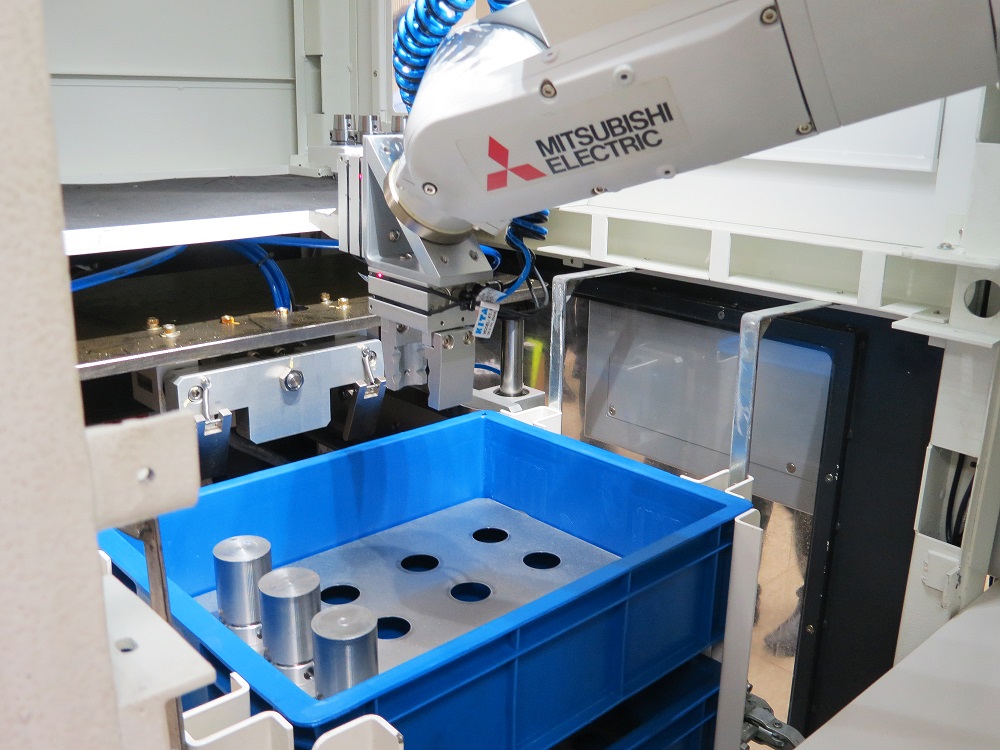

- Integrated CNC Automation: The 6-axis Mitsubishi robot loads, unloads, and flips parts automatically—cutting idle time and maximizing spindle uptime.

- Unattended Operation: Optional pallet trays enable extended unmanned runs for overnight or weekend production.

- Superior Stability & Rigidity: Heavy Meehanite casting, 35 mm roller guideways, and 32 mm pre-tensioned ballscrews maintain excellent rigidity and thermal balance.

- Precision & Repeatability: Mitsubishi servo motors and a fully synchronized control system deliver consistent accuracy within ±0.00015″.

- Scalable Automation Solutions: Pair with Absolute’s A+ Automation accessories—MIU Ethernet interface, Auto Door Kits, and LoadMate Plus™—for a complete turnkey automation cell.

- Reduced Labor Costs: By combining machining and robotics, the Robo Series minimizes manual handling, improves operator safety, and boosts throughput.

Manufacturers benefit from shorter cycle times, improved reliability, and continuous part production, giving them a competitive edge in high-mix/low-volume environments where flexibility and efficiency matter most.