Quicktech i-Twin Series – 7-Axis Twin Spindle Mill-Turn Centers with B-Axis

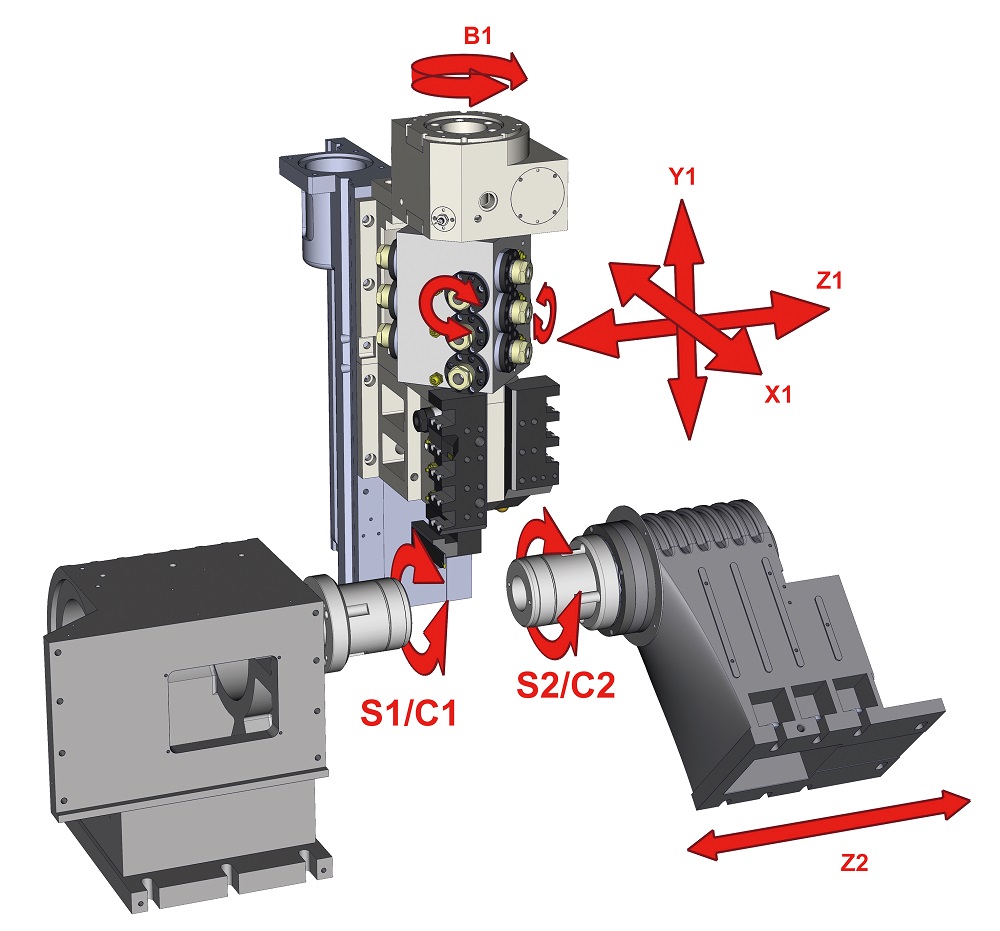

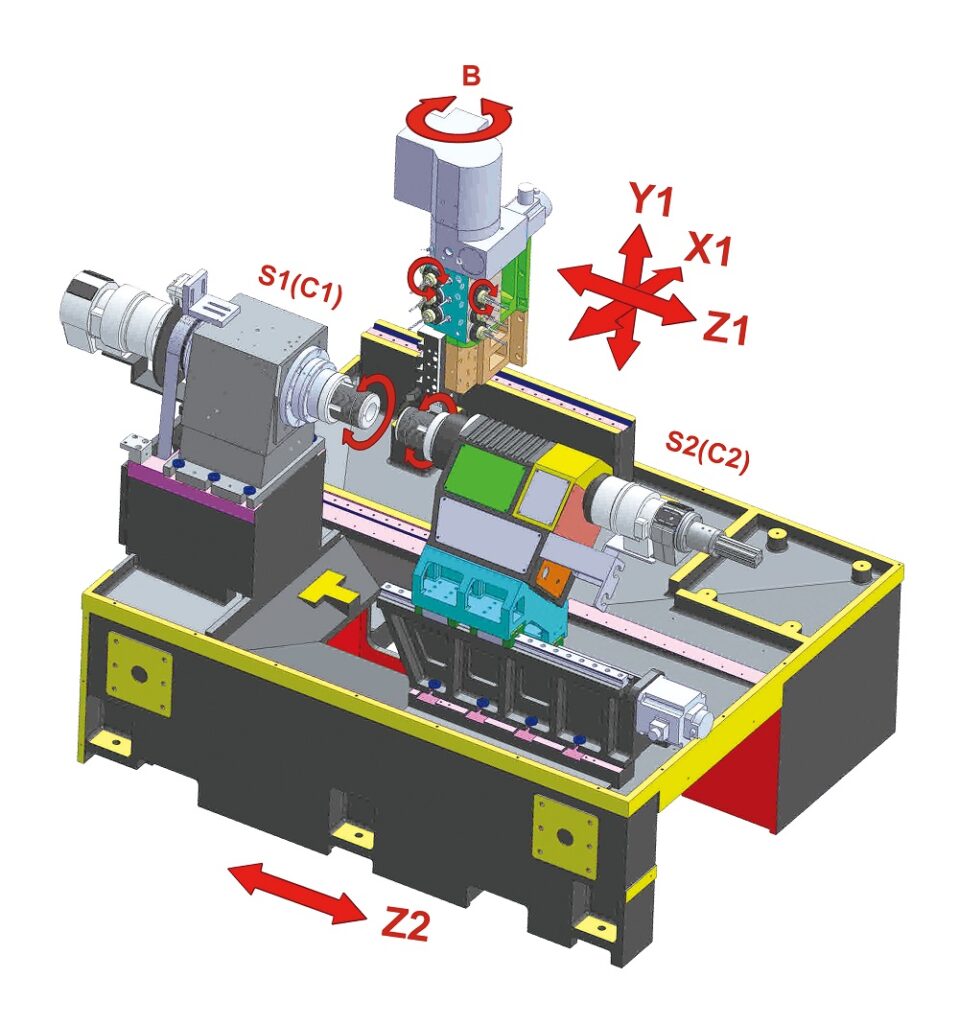

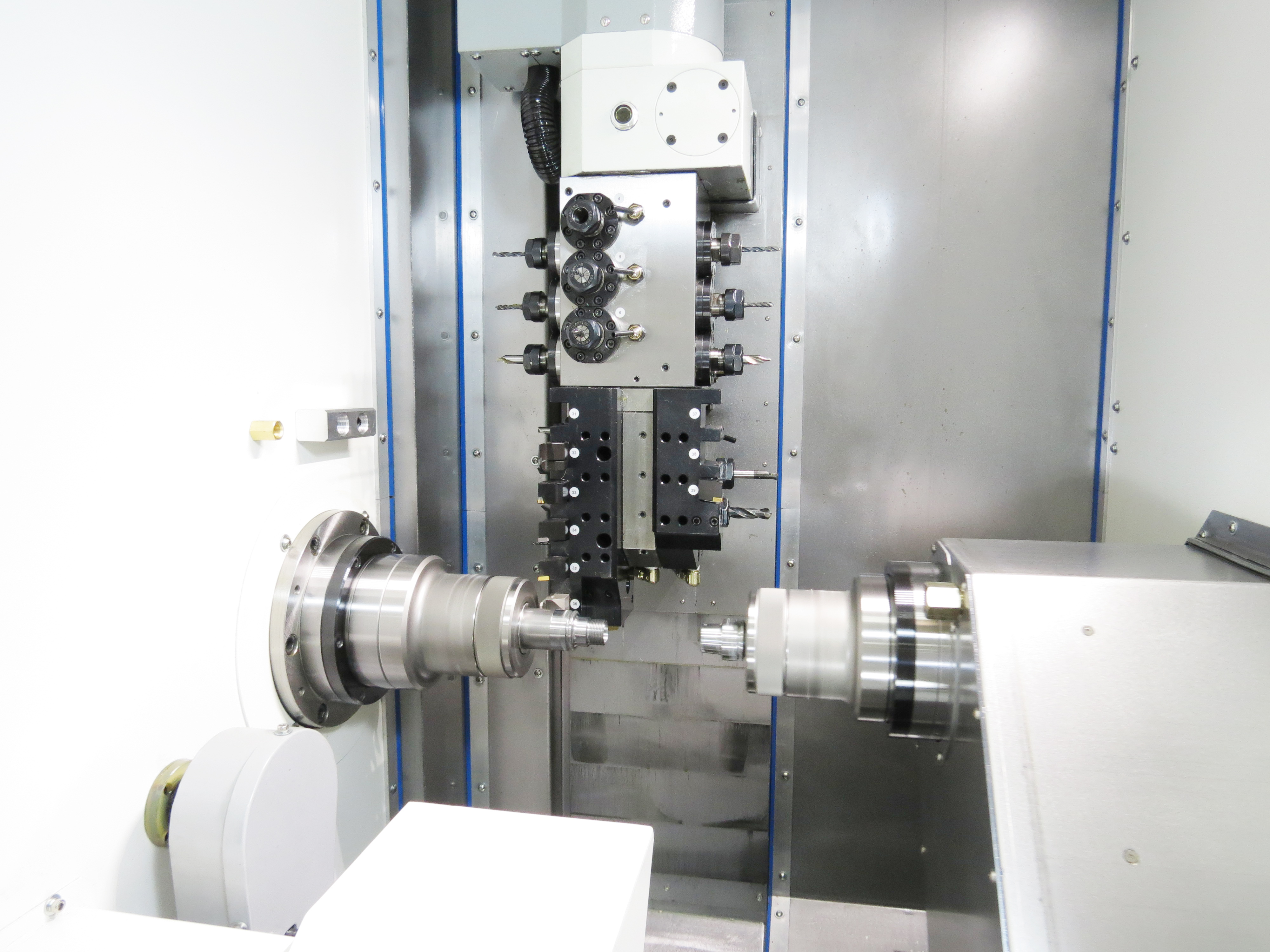

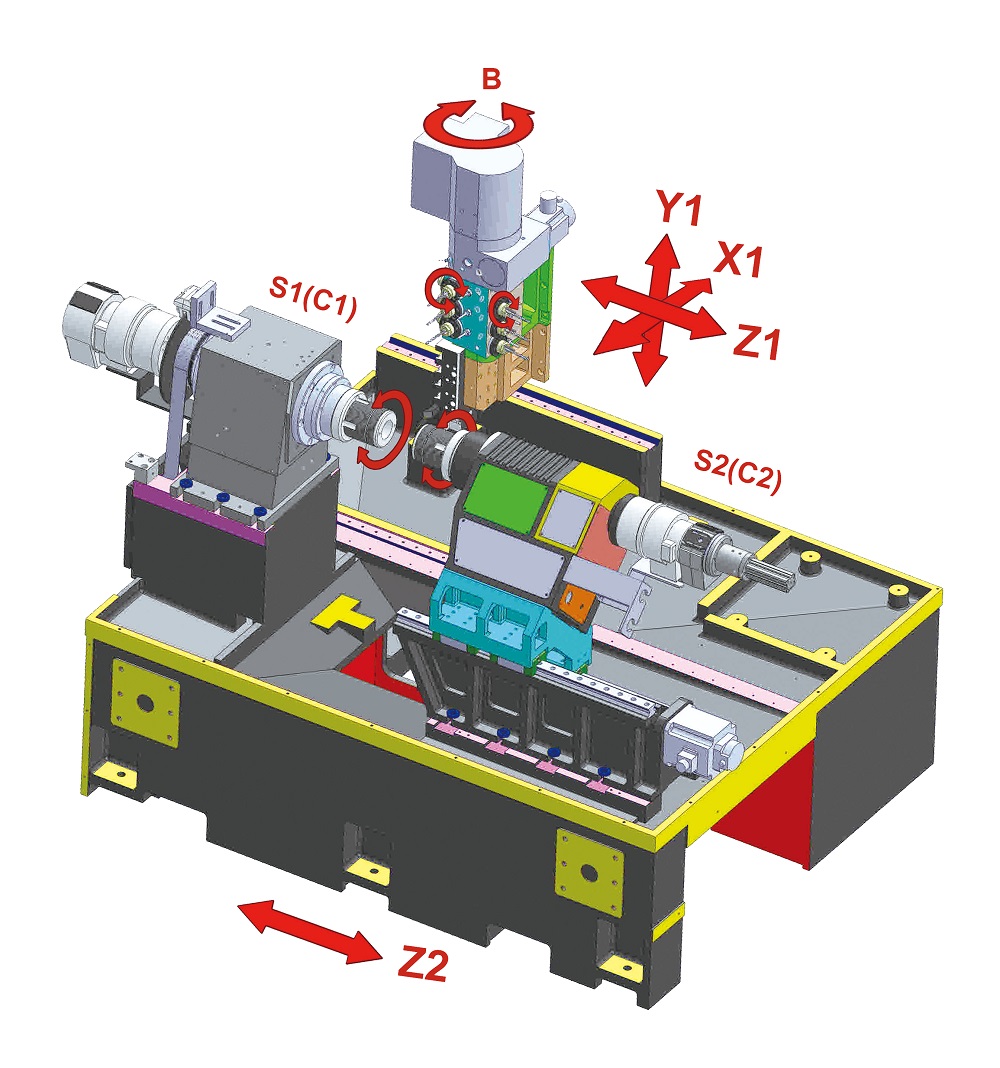

The QuickTECH i-42 Twin and i-60 Twin are compact, high-precision, high-production mill-turn centers built on rigid Meehanite castings. With 7 axes, dual synchronized spindles, a shared 4-axis (X/Y/Z/B) gang-type vertical tool post, and 30 total tools, these machines deliver complete done-in-one machining for complex bar work in medical, aerospace, automotive, and electronics where accuracy, surface finish, and throughput matter most. Competes head-to-head with Haas, Doosan, DMG Mori, and Mazak.

Key Features

- Twin spindles for done-in-one:

- Main: 15 HP, 6,000 RPM, 42 mm (1.65″) bar on i-42 / 60 mm (2.36″) on i-60.

- Sub: 7.5 HP, 6,000 RPM, 30 mm bar; synchronized part transfer; full C-axis on both.

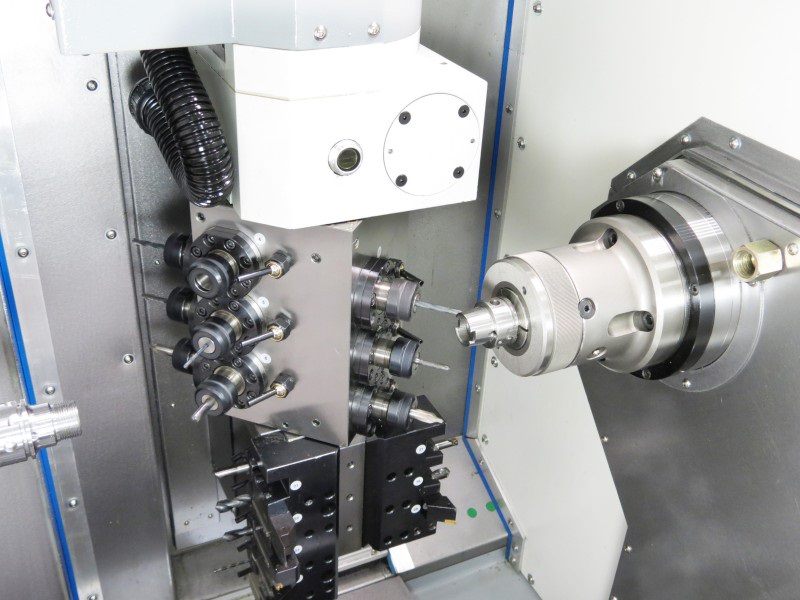

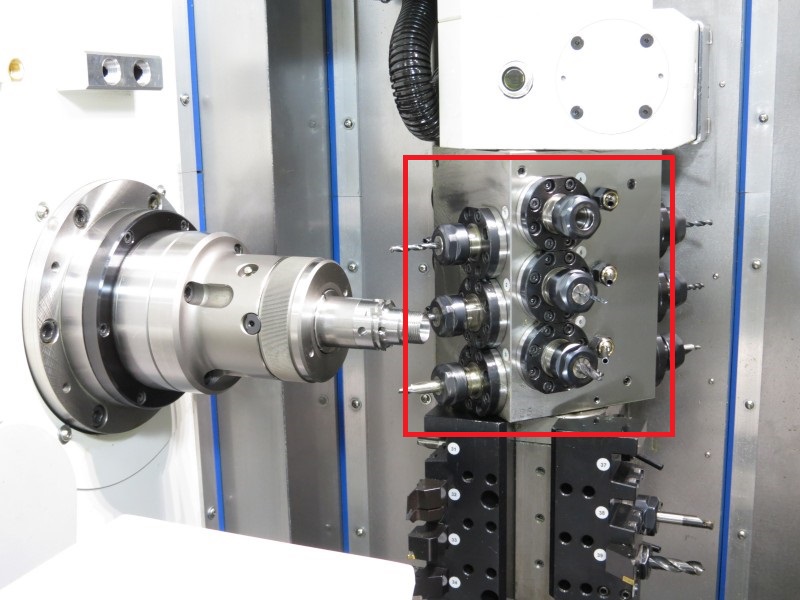

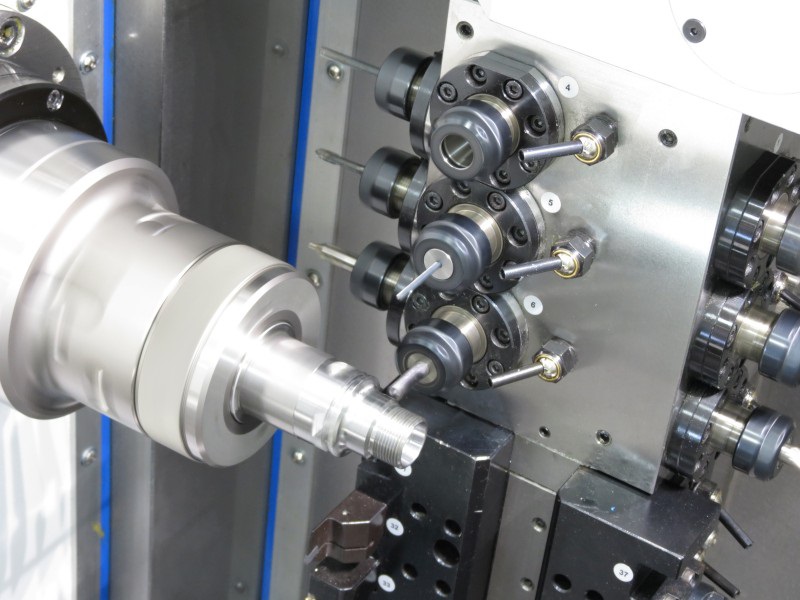

- Tooling system built for speed: 4-axis gang tooling (X/Y/Z + 360° B) shared between spindles; 30 tools total (9 OD, 9 ID, 12 live); 2 HP live-tool motor; near-zero tool-change time. Rigid tapping standard.

- Motion platform: 35 mm roller ways, 32 mm ballscrews, high rapids; repeatability ±0.00015″; positioning ±0.0002″.

- Controls: Mitsubishi M80A (10.4″ LCD, 3D simulation, Ethernet; 3-yr CNC warranty); optional Fanuc OiT-F Plus (15″ LCD, dual-channel, Manual Guidance i).

- Production essentials included: collet chucks (DIN-173E-42B / DIN-185E-60B), parts catcher, parts & chip conveyors, 400 PSI coolant, bar feeder interface, auto lube.

Specifications

| Item / Model |

i-42 Twin

Request a Quote

|

i-60 Twin

Request a Quote

|

|---|---|---|

|

Main Spindle Capacity |

||

|

Max Bar Working Capacity |

1.65″ |

2.36″ |

|

Max Turning Length |

9.8″ |

9.8″ |

|

Spindle Speed Range (std.) |

6,000 RPM |

4,000 RPM |

|

Spindle Motor |

15 HP |

15 HP |

|

C-Axis Increment |

.001° |

.001° |

|

Sub-Spindle Capacity |

||

|

Max Bar Working Capacity |

1.65″ |

1.65″ |

|

Max Turning Length |

3.94″ |

3.94″ |

|

Spindle Speed Range |

6,000 RPM |

6,000 RPM |

|

Spindle Motor |

7.5 HP Integral Motor |

7.5 HP Integral Motor |

|

C-Axis Increment |

.001° |

.001° |

|

Travel and Feed |

||

|

Rapid Traverse Rate |

1,181″/min. |

1,181″/min. |

|

Tooling System |

||

|

Tooling Type |

Gang Tool / Servo Y-Axis / KM-25 Quick Change |

Gang Tool / Servo Y-Axis / KM-25 Quick Change |

|

Number of Turning Tools |

6 O.D. (5 + 1 Cut Off) & 5 I.D. |

6 O.D. (5 + 1 Cut Off) & 5 I.D. |

|

Square Shank Size |

.75″ (20mm) |

.75″ (20mm) |

|

Boring Bar Capacity |

.75″ (ER-20) |

.75″ (ER-20) |

|

B-Axis |

360° |

360° |

|

B-Axis Index Time |

.3 Seconds 90° / 6 Seconds 360° |

.3 Seconds 90° / 6 Seconds 360° |

|

Number of Live Tools |

12 |

12 |

|

Live Tool Spindle Motor |

2 HP |

2 HP |

|

Live Tool Spindle Speed |

4,000 |

4,000 |

|

Live Tool Shank |

ER-20 Collet |

ER-20 Collet |

|

General |

||

|

CNC Control |

Mitsubishi M80A |

Mitsubishi M80A |

|

Machine Dimensions with Chip Conveyor |

138″ x 71″ x 75″ |

138″ x 71″ x 75″ |

|

Machine Weight |

8,360 lbs. |

8,360 lbs. |