Scytec Machine Monitoring and Communications Systems

Scytec is one of the original machine monitoring companies in North America. The company was a member of the team that created and launched MTConnect. For 20+ years, Scytec has been a leader in providing manufacturers useful and quality OEE (overall equipment effectiveness) machine monitoring data.

All manufacturers have goals, but justifying those goals can sometimes be hard to quantify, however, by analyzing current data output, those goals can be quickly realized. When a manufacturer understands live data such as input/output, performance, time, energy, and overall machine health, then intelligent decisions can be made with certainty. No longer does a team, or individual, have to say they think something will work, rather accumulated data in charts, dashboards and reports will fortify their decision.

Want to know more about Scytec’s DataXchange Machine Monitoring and Communications Systems can do for your business? Click the link below!

Solutions

Don’t Guess! Manage by Facts using Easy & Affordable Industry 5.0 Data

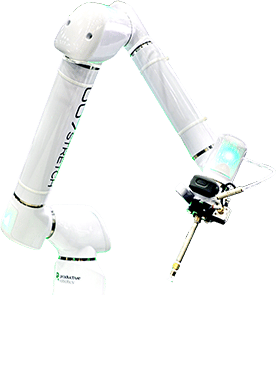

Industry 4.0 focused on the Internet of Things (IoT) through connectivity between machines to receive useful and relevant data that had never been properly measured. Industry 5.0 adds additional data benefactors through the combination of human workers and machines, such as robots, to create more advanced and efficient manufacturing processes. This is also known as human-centric manufacturing, which is the combination of the strength, speed, repeatability and precision of automation combined with the intelligence, flexibility and skill of human operators.

Industry 5.0 is designed to be inclusive of workers, leveraging the strengths of humans and machines to improve manufacturing, thus, creating an even SMARTER factory. Today’s SMART factories include human workers functioning with their robotic counterparts to increase productivity, efficiency, eliminate waste, reduce power usage, and drill deeper into data they didn’t even know existed.

Applications

How will DataXchange Machine Monitoring Solutions help Manufacturers:

- Manage by fact not speculation

- Access new and old data anytime/anywhere

- Monitor legacy machines

- Empower operators

- Be proactive rather than reactive

- Become more efficient

- Timely manage machine maintenance

- Get notified of issues in real-time through triggered emails and texts

- Display various messages on dashboards for others to see

- View data from external systems

- Build Dataxchange easily as your company grows

- Personalize and customize data reporting

- Share data results in real-time

What Types of Data can be Monitored over DataXchange’s Real-Time Viewer:

- Machine utilization

- Machine productivity

- Measure job performance against targets

- Spindle feed rates & overrides

- Rapids

- Alarms

- Equipment status

- Time spent in M0 & M1

- Downtime

- Idle time

- Program numbers

- Part numbers

- Part counts

- Operator productivity

- Display shop floor layouts

- View documents

- View the shop floor in real time