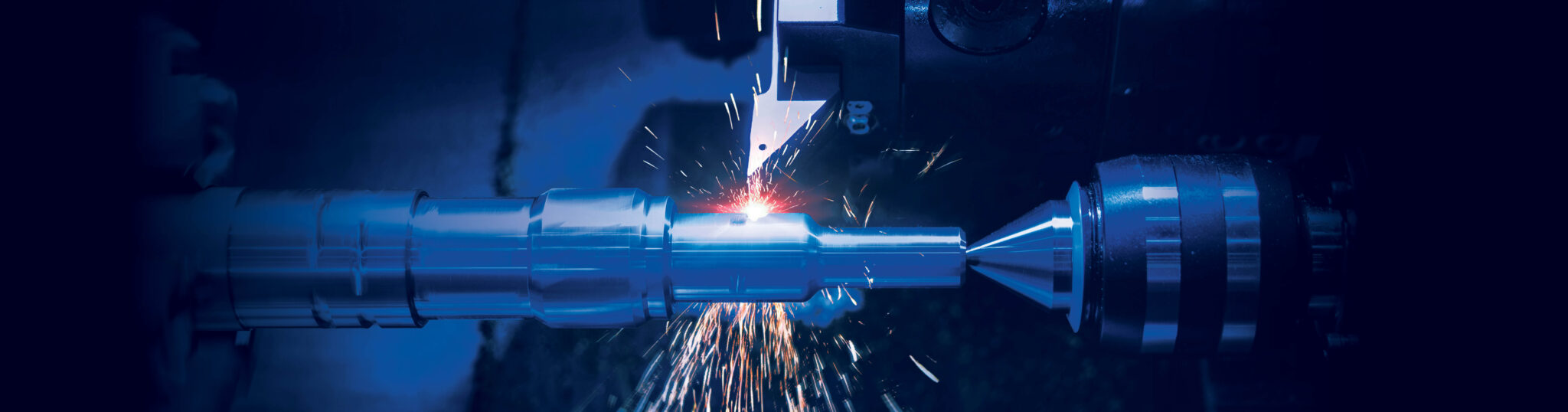

CNC Vertical Machining Centers (VMCs)

Vertical machining centers, with their vertically oriented spindle that approaches the workpiece from above, are a cost-effective choice for both small job shops and larger manufacturing operations. These machines allow for efficient and precise machining, enabling five-sided positional and simultaneous machining of complex parts. Additionally, the incorporation of rotary tables or rotary axes in the machine’s headstock and spindle enables the use of shorter cutting tools and facilitates drilling series of compound angle holes. Discover an extensive range of top-of-the-line vertical machining centers and drill/tap machining centers at Absolute Machine Tools. We proudly offer machines from renowned brands such as Johnford and Seiki, ensuring exceptional quality and performance.

Our selection of vertical machining centers and drill/tap machining centers is designed to cater to a wide range of manufacturing needs. Whether you require high-speed machines for rapid mass production and tapping, or box-way, geared-head, C-frame 50-taper machines with powerful spindles up to 50 HP and impressive X-axis travel up to 6 meters, we have the perfect solution for you. Choose from traveling column machines, single and twin spindle machines, and specialized units specifically tailored for mold and die applications and electrode manufacturing. We also provide rotary ultrasonic assisted machines, offering innovative solutions for enhanced machining capabilities. With options for five-axis capability and various workpiece and tool changing systems, our machines provide flexibility and versatility to meet your unique requirements.

Upgrade your machining capabilities with Absolute Machine Tools’ vertical machining centers and drill/tap machining centers. Experience superior performance, versatility, and precision. Browse our range of machines today and unlock new possibilities for your manufacturing processes. Contact us now to discover how our advanced solutions can drive your success.

Machines

Oems

When it comes to vertical machining centers, Johnford is a name you can trust. Johnford’s VMCs offer exceptional precision, reliability, and cutting-edge technology. Designed to handle a wide range of machining applications, Johnford’s vertical machining centers deliver superior performance and ensure optimal results. With robust construction and advanced features, Johnford’s machines provide excellent stability and accuracy, enhancing productivity and efficiency. Whether you need to perform milling, drilling, or tapping operations, Johnford’s vertical machining centers are engineered to meet your needs. Trust in Johnford’s expertise and experience the difference their vertical machining centers can make in optimizing your manufacturing processes. Elevate your productivity and precision with Johnford’s top-of-the-line vertical machining centers.

Seiki vertical mill/drill/tap centers are the fastest CNC milling and tapping centers in their class. These machines will exceed the demands of any manufacturer with high volume, high precision machining needs. The accuracy and quality achieved with Seiki’s machining centers along with the compact footprint and competitive price make this mill a valuable addition for shops producing a wide variety of components. These mills can be utilized for both complete parts and secondary operations, and they are designed to offer seamless integration, streamlining your workflow and enhancing productivity. The intricate milling abilities that Seiki machining centers provide make these mills great for final machining of metal injection molding (MIM) parts. With sturdy construction and cutting-edge features, Seiki’s drill tap centers deliver superior performance and ensure consistent, accurate results.

Asia Pacific Elite Corp. Vertical Machining Centers set new standards for precision, reliability, and efficiency. With a commitment to excellence, APEC machines are engineered to meet the rigorous demands of modern manufacturing, combining state-of-the-art technology with APEC’s hallmark precision engineering, delivering unmatched performance in speed, accuracy, and durability.

When it comes to vertical machining centers, Johnford is a name you can trust. Johnford’s VMCs offer exceptional precision, reliability, and cutting-edge technology. Designed to handle a wide range of machining applications, Johnford’s vertical machining centers deliver superior performance and ensure optimal results. With robust construction and advanced features, Johnford’s machines provide excellent stability and accuracy, enhancing productivity and efficiency. Whether you need to perform milling, drilling, or tapping operations, Johnford’s vertical machining centers are engineered to meet your needs. Trust in Johnford’s expertise and experience the difference their vertical machining centers can make in optimizing your manufacturing processes. Elevate your productivity and precision with Johnford’s top-of-the-line vertical machining centers.

Seiki vertical mill/drill/tap centers are the fastest CNC milling and tapping centers in their class. These machines will exceed the demands of any manufacturer with high volume, high precision machining needs. The accuracy and quality achieved with Seiki’s machining centers along with the compact footprint and competitive price make this mill a valuable addition for shops producing a wide variety of components. These mills can be utilized for both complete parts and secondary operations, and they are designed to offer seamless integration, streamlining your workflow and enhancing productivity. The intricate milling abilities that Seiki machining centers provide make these mills great for final machining of metal injection molding (MIM) parts. With sturdy construction and cutting-edge features, Seiki’s drill tap centers deliver superior performance and ensure consistent, accurate results.

Asia Pacific Elite Corp. Vertical Machining Centers set new standards for precision, reliability, and efficiency. With a commitment to excellence, APEC machines are engineered to meet the rigorous demands of modern manufacturing, combining state-of-the-art technology with APEC’s hallmark precision engineering, delivering unmatched performance in speed, accuracy, and durability.

Experience the Absolute Advantage

At Absolute Machine Tools, we offer a diverse selection of vertical machining centers to suit various applications. Our lineup includes machines from industry-leading brands, ensuring top-notch quality and reliability. From high-speed machines with rapid mass production capabilities to robust box-way, geared-head, C-frame 50-taper machines with powerful spindles and extended X-axis travel, we have the perfect solution for your machining requirements.

Specialized Machines for Advanced Applications

We understand that different industries demand specialized machining solutions. That’s why we provide specialized vertical machining centers for specific applications. Whether you need machines for mold and die manufacturing, electrode manufacturing, or rotary ultrasonic assisted machining, we have you covered. Our machines are designed to deliver precise results and exceptional efficiency in even the most demanding applications.

Unleash the Power of Five-Axis Capability

To expand your machining capabilities, many of our VMCs come with advanced five-axis capability. This enables you to achieve complex machining tasks with ease, unlocking new levels of creativity and precision. Experience the freedom to create intricate parts and components with efficiency and accuracy.

Tailor-Made Solutions for Your Needs

At Absolute Machine Tools, we understand that each customer has unique requirements. That’s why we offer customizable options to ensure our VMCs meet your specific needs. Whether it’s workpiece and tool changing systems or additional features to enhance performance, we can tailor the machine to optimize your productivity.

Trust in Absolute Machine Tools

With our vast experience and commitment to excellence, Absolute Machine Tools is your trusted partner in vertical machining centers. We provide not only high-quality machines but also exceptional customer support and service. Our team of experts is ready to assist you in finding the perfect machine for your manufacturing needs.

Elevate your machining capabilities with Absolute Machine Tools’ vertical machining centers. Explore our extensive range and unleash the full potential of your production. Contact us today to discover how our cutting-edge solutions can transform your manufacturing processes and drive your success.

Frequently Asked Questions About VMCs

A CNC vertical machining center is a precision machine tool equipped with CNC technology. It is designed for efficient and accurate machining operations on various materials, primarily used in manufacturing and metalworking industries.

A CNC vertical machining center operates by utilizing programmed instructions to control the movement of the machine’s cutting tools. These instructions are entered into the machine’s computer, allowing for precise and automated movements along multiple axes, such as X, Y, and Z, to shape and carve the workpiece.

Using a CNC vertical machining center offers several advantages, including:

1. Precision: CNC technology ensures highly accurate and repeatable machining operations.

2. Efficiency: Automated operations reduce manual labor and increase productivity.

3. Versatility: Capable of machining complex geometries and various materials.

4. Flexibility: Easy adaptation to different machining tasks through program modifications.

5. Time and Cost Savings: Reduced setup times and minimized material waste.

6. Improved Safety: Reduced risks associated with manual machining operations.

A CNC vertical machining center can efficiently process a wide range of materials, including metals (such as aluminum, steel, and titanium), plastics, composites, and even certain types of wood. The choice of cutting tools and machine settings may vary depending on the material being machined.

CNC vertical machining centers are utilized in various industries, including:

1. Aerospace: Manufacturing aircraft components and parts.

2. Automotive: Machining engine components, chassis parts, and more.

3. Medical: Fabricating medical devices, implants, and surgical instruments.

4. Electronics: Producing intricate circuit boards and electronic components.

5. Mold and Die: Creating molds and dies for plastic injection and metal casting.

6. General Manufacturing: Catering to diverse machining needs across industries.

Yes, CNC vertical machining centers are available in a range of sizes, with some models specifically designed to handle large workpieces. These machines offer ample workspace and table capacities to accommodate various sizes of workpieces.

When selecting a VMC, consider factors such as:

1. Machine size and table capacity; Of first importance are the machine’s workpiece capacity and the size of the machine itself. Worktable dimensions and weight capacities determine the size of the largest workpiece that the machine can handle. Some machines offer a compact design that can permit machining of larger workpieces when floor space is limited.

2. Spindle speed and power

3. Number of axes and their travel range

4. Control system and software capabilities

4. Tool magazine capacity and tool-changing speed; Factors included in choosing an automatic tool changer include its capacity in terms of number, weight and size of the tools, as well as chip-to-chip changeover times

5. Production volume; Anticipated production volumes influence selection of workpiece handling equipment. Automatic part loading and chip removal expedite long production runs, while features that minimize setup time facilitate changeovers in high-turnover short-run situations.

6. Component material; Workpiece material machining characteristics dictate machine performance requirements. For example, if most work includes finishing of softer materials, high-speed machining capability will produce the best results. On the other hand, heavy roughing of hard materials demands low-speed torque and maximum machine rigidity.

7. Advanced features like probing and automatic tool measurement

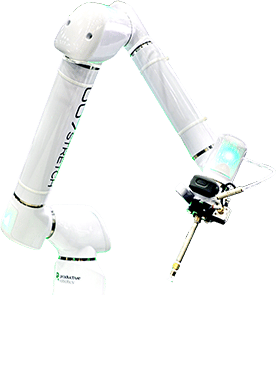

Yes, a CNC vertical machining center can be seamlessly integrated with other manufacturing systems, such as robotics, automated material handling, and CAD/CAM software. This integration enhances overall production efficiency, reducing manual intervention and optimizing workflow.

Regular maintenance is crucial for the optimal performance of a CNC vertical machining center. Maintenance tasks include cleaning, lubrication, inspection of critical components, and periodic calibration. It is recommended to follow the manufacturer’s guidelines and schedule professional servicing when necessary.

Absolute Machine Tools offers reliable VMCs from reputable machine tool manufacturers. With a proven track record, excellent customer support, and a comprehensive warranty, we are the premier provider of VMCs.