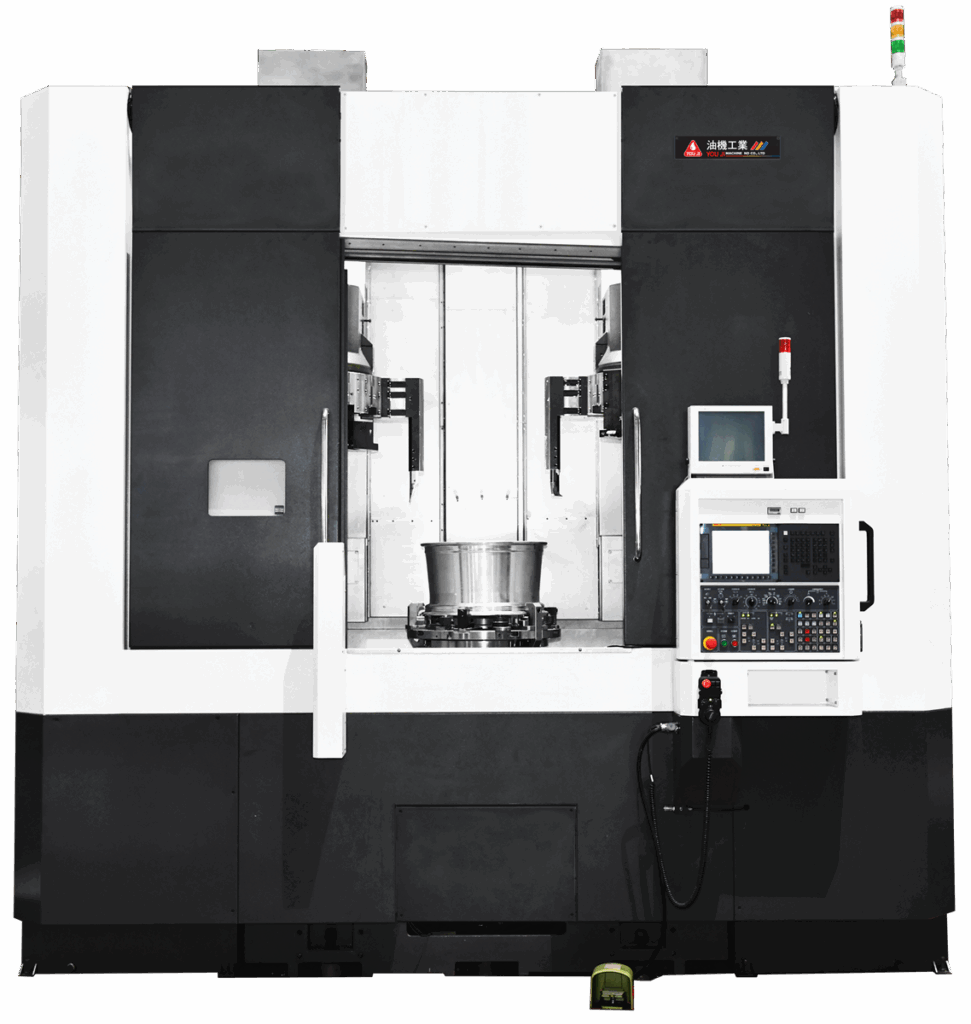

You Ji WV Series Vertical Turning Centers for Aluminum Wheels & Parts

The You Ji WV Series vertical turning lathes are specifically engineered for high-volume machining of pristine aluminum wheels and similar components. These compact, high-precision, high-production CNC machines can operate as stand-alone machining cells or be seamlessly integrated into flexible, automated manufacturing systems. Depending on the specific model, the WV Series can accommodate wheel diameters of up to 26″ (660 mm).

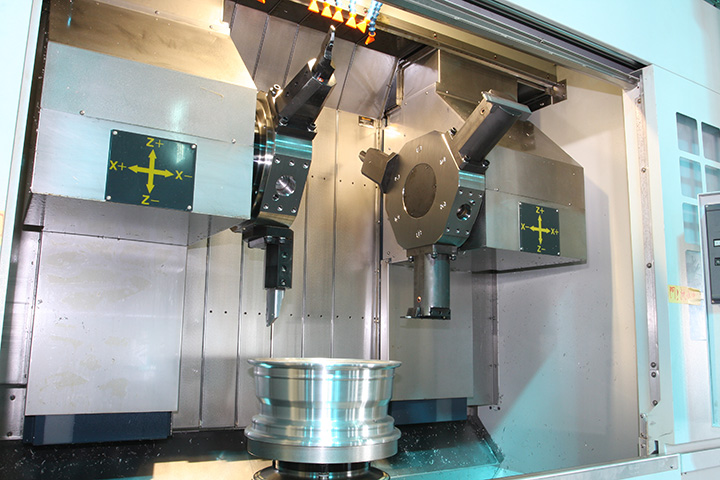

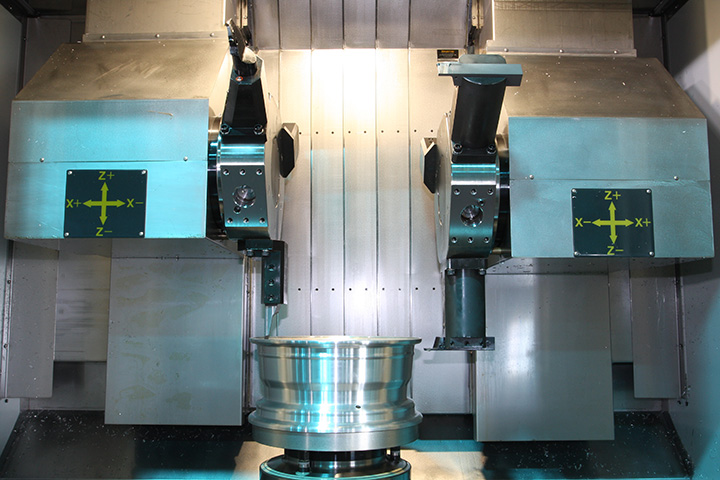

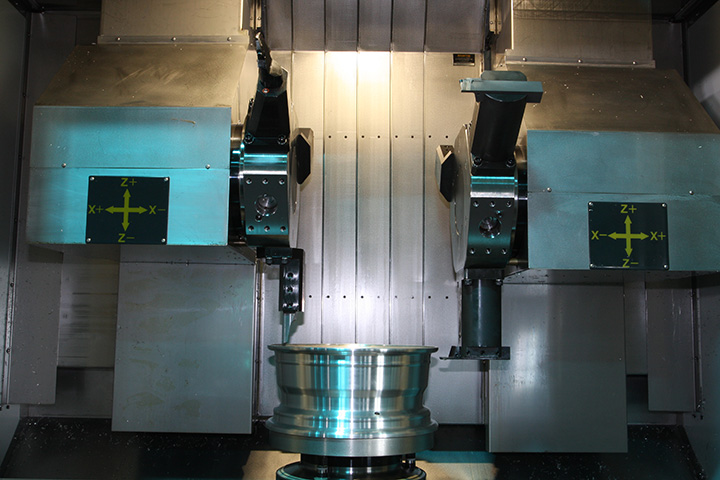

Each model features a vertical column and base constructed from a single-piece Meehanite® casting, heavily ribbed to minimize thermal distortion and dampen vibration for enhanced machining stability. The X-axis utilizes a rigid square ram mounted on box ways, while the Z-axis incorporates roller-type linear guideways for smooth and precise motion. The square ram, combined with specially engineered internal sliding covers, virtually eliminates chip accumulation issues.

High-speed guideway systems enable rapid traverse rates of 600 in/min (15.2 m/min). A robust 6-position hydraulic vertical hex turret is mounted on the ram, equipped for heavy-duty bolt-on tooling. The turret delivers an index time of just 0.8 seconds and features automatic shortest-path tool selection for maximum efficiency. A standard chip wash system is included to direct chips efficiently to the conveyor, ensuring a clean and reliable machining environment.

As with all You Ji CNC machine tools, customized models are available upon request.

Specifications

| Item / Model |

WV-550E

Request a Quote

|

WV-550E2T

Request a Quote

|

WV-600E

Request a Quote

|

WV-600E2T

Request a Quote

|

|---|---|---|---|---|

|

Chuck Size (in.) |

20″ |

20″ |

24″ |

24″ |

|

Max Swing (in.) |

27.5″ |

27.5″ |

33.5″ |

33.5″ |

|

Wheel Dia. (in.) |

13″ – 22″ |

13″ – 22″ |

17″ – 26″ |

17″ – 26″ |

|

Z Axis Travel (in.) |

14.96″ |

14.96″ |

21.65″ |

21.65″ |

|

# of Axis |

2 |

4 |

2 |

4 |

|

Tool System |

Hex Turret 10″ Sq. Ram |

(2) Hex Turrets on 10″ Sq. Rams |

Hex Turret 10″ Sq. Ram |

(2) Hex Turrets on 10″ Sq. Rams |

|

Spindle HP |

30 (60 opt.) |

60 |

30 (100 opt.) |

100 |

|

RPM |

2,000 |

2,000 |

1,500 (2,000 opt.) |

1,500 (2,000 opt.) |

|

APC |

No |

Optional |

No |

Optional |

|

Weight (lbs.) |

22,000 |

32,000 |

27,500 |

44,000 |