You Ji

You Ji Machine Industrial Company, Ltd.

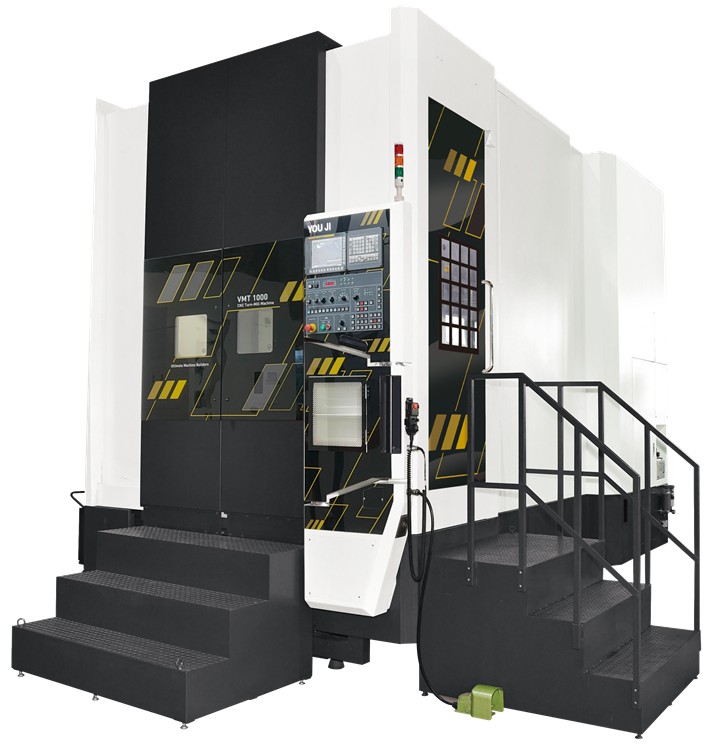

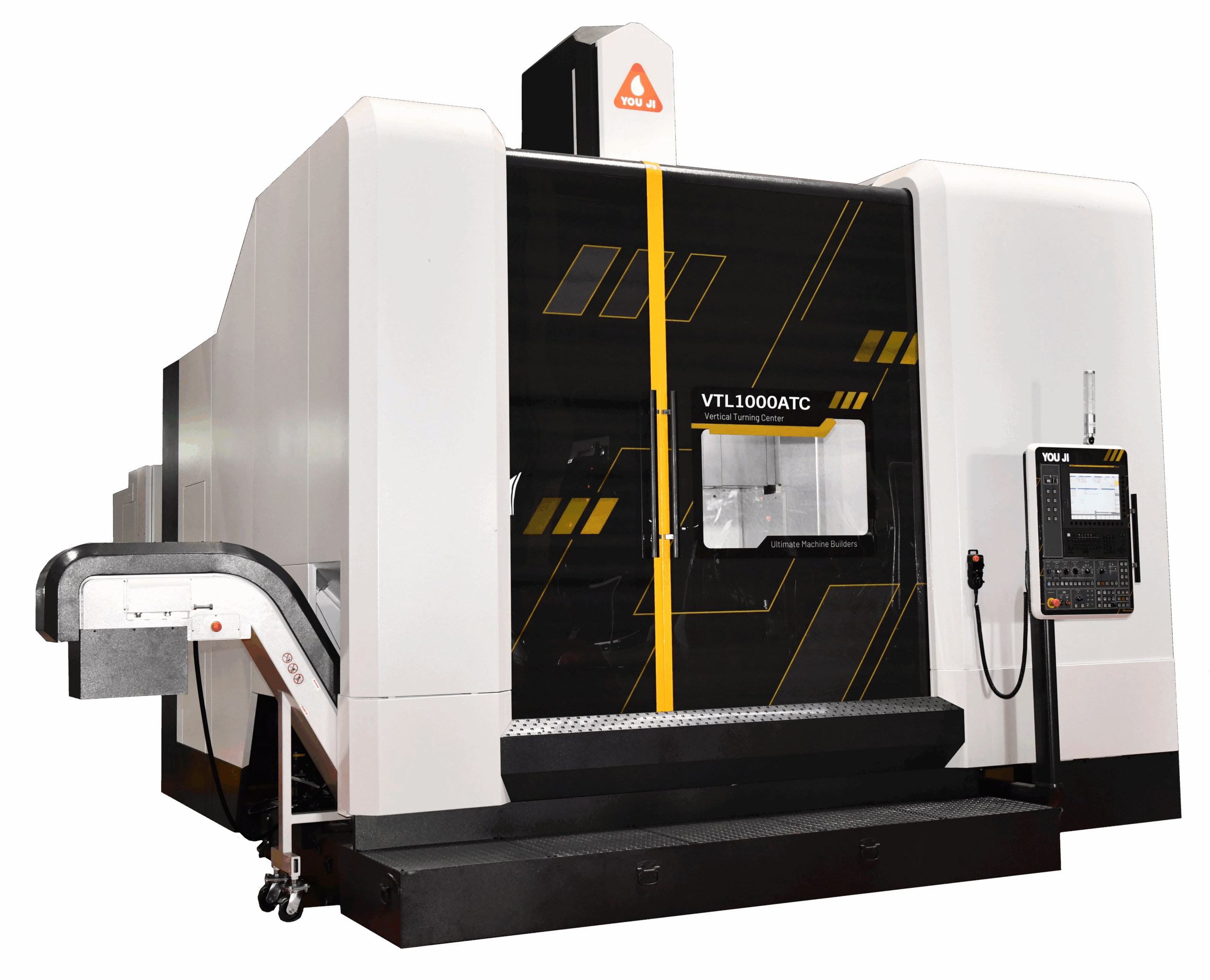

You Ji is a leading Taiwanese manufacturer of CNC machine tools, renowned for its expertise in large vertical turning lathes (VTLs) and vertical turning centers (VTCs). Established in 1978 and headquartered in Kaohsiung, Taiwan, You Ji has built a strong reputation for producing heavy-duty, highly rigid machines capable of handling large and complex workpieces. Chuck sizes range from 8″ to 315″ with turning heights up to 20′.

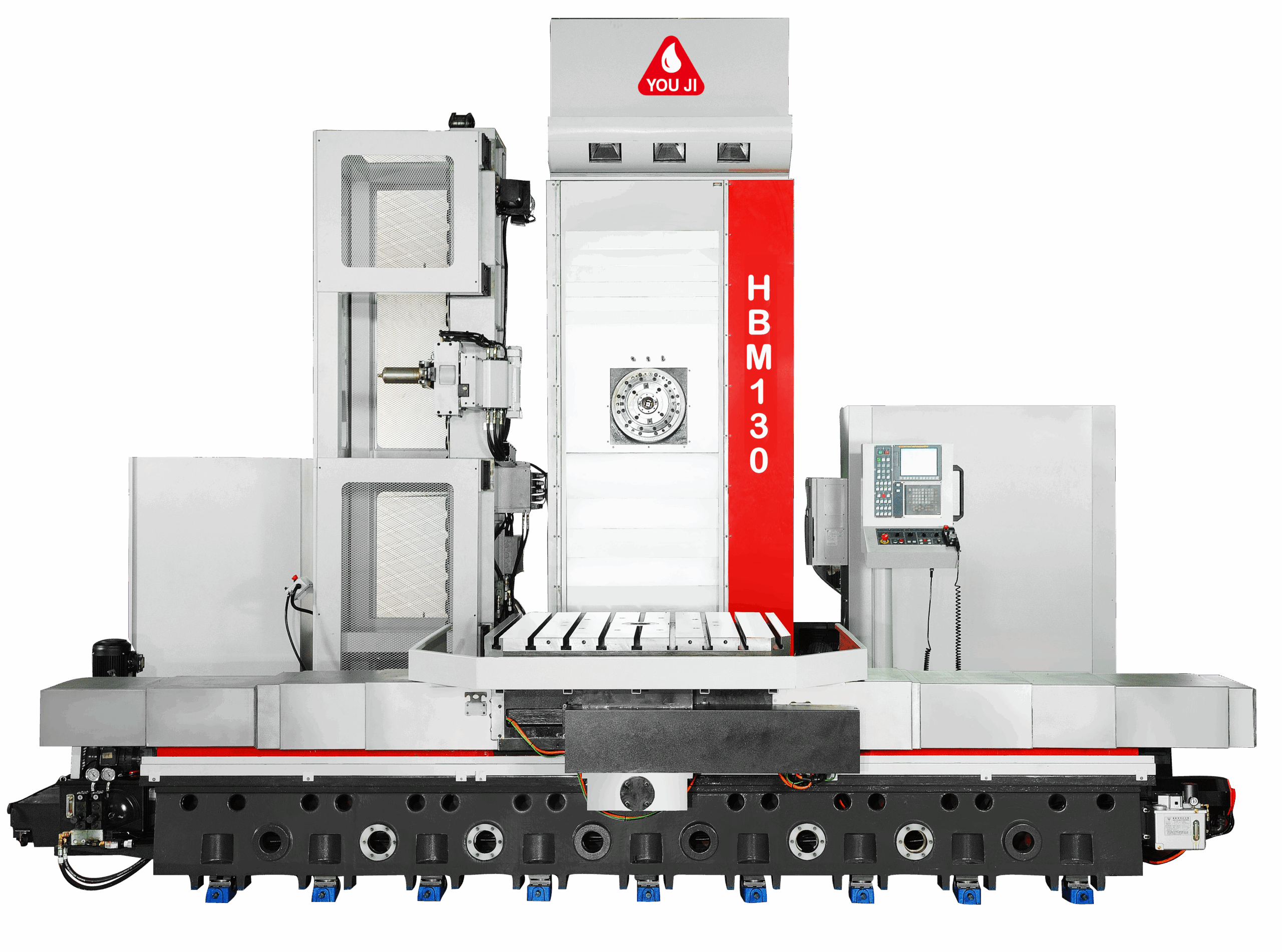

You Ji offers a diverse range of machine tools tailored to various industrial applications:

You Ji’s machines are widely utilized across industries such as aerospace, automotive, energy, and heavy equipment manufacturing. Their commitment to quality and innovation has positioned them as a leading CNC machine tool builder in Taiwan and a respected name in global manufacturing. Absolute has sold, installed, and serviced more than 2,000 You Ji vertical lathes across the U.S. and in countries such as Mexico, Canada, Romania, China, and India.

Why Choose a You Ji VTL?

Machines

More Than VTLs

Although known for VTLs, You Ji also provides machine tool solutions for: