You Ji HBM Series – Table-Type Horizontal Boring Mills

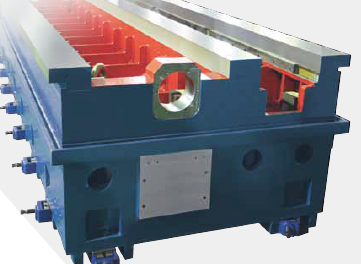

The You Ji HBM series of table-type horizontal boring mills feature a moving column for the Z axis and a moving table for the X axis. The design provides full support of the table over the entire X axis travel and results in maximum rigidity and accuracy, and eliminates the need for additional supports to withstand high table loads. The X axis features a unique triple box guideway with a hydrostatic way structure.

Standard X-Y-Z travels for the HBM-130 is 118″ x 102.4″ x 65″ (2997 mm x 2601 mm x 1651 mm).

The machine features precision ground and induction hardened box ways in all linear axes. All mating surfaces are hand scraped and coated with Turcite-B, and the ways are force lubricated via a pressurized automatic oil system. Large diameter, pre-tensioned ballscrews assure accurate positioning. All linear axes feature Heidenhain linear scales.

The triple-cooled 60 hp, 2,500 rpm spindle motor with 2 speed gear drive produces 1,452 lb-ft. of torque at 218 rpm.

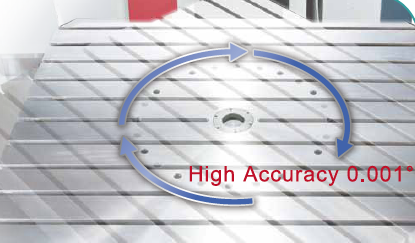

The standard rotary B-axis has a hydrostatic bearing system and is driven via a high-precision dual pinion mechanism. With the high-resolution encoder, B-axis accuracy is +/-7.5 arc seconds with +/-5 arc seconds repeatability. Standard features includes a stand-alone heavy duty 60 tool (80 and 120 tool optional) arm type automatic tool changer, a comprehensive chip removal system, a high volume coolant system, and 300 psi coolant through the spindle. The standard Fanuc 31iM-B control features the Fanuc Alpha I servo system with 1,000,000 pulse encoders.

A comprehensive selection of options enables users to custom-tailor the machine’s capabilities to specific production needs. Choices include axis extenders, rotary tables, pallet changers, tool and part probes and high-pressure coolant systems.

Don’t see what you need? Absolute Machine Tools together with Johnford can customize a HBM series machine to fit your requirements. Click RFQ and let us know what your needs.

Specifications

| Item / Model |

HBM-130

Request a Quote |

|---|---|

|

Photos |

|

|

Spindle Bar (in.) |

5.12 |

|

Table Size (in.) |

70.86 x 86.6 |

|

Table Load (lbs.) |

55,000 |

|

X Travel (in.) |

118 |

|

Y Travel (in.) |

102.4 |

|

Z Travel (in.) |

65 |

|

W Travel (in.) |

29.5 |

|

Spindle Drive |

2 Speed Gear Box |

|

Spindle HP |

60 |

|

RPM |

0 – 2,500 |

|

ATC Capacity |

60 (80 / 120 opt.) |

|

Weight (lbs.) |

130,000 |

FAQs

On a table-type boring mill, what is the maximum load capacity?

Absolute Machine Tools boring mills that can handle table loads of up to 55,000 lbs.

What are some examples of parts made with boring mills?

Boring mills are frequently used for oil and gas frack blocks, large manifolds, gearbox housings for a variety of industries, energy-related parts, transmission housings, and forgings.

Do your boring mills come standard with a B-axis rotary table or just an indexer?

At Absolute Machine Tools, our machines come standard with a full B-axis rotary table (.001 degree).