You Ji AH Series – Oil Country Horizontal Slant Bed Turning Centers

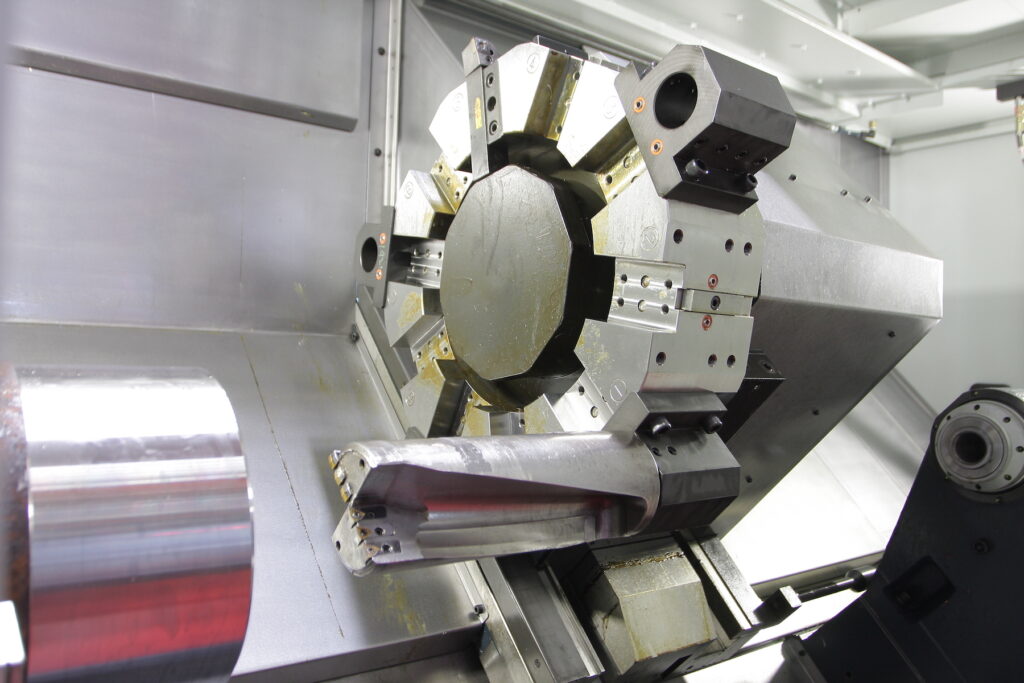

The You Ji AH Series horizontal slant bed lathes are engineered for heavy-duty turning applications, particularly in the oil and gas sector. These machines feature a robust 45° slant bed and a 55° inclined cross slide, enhancing structural rigidity and improving operator accessibility. Built for strength and long-term reliability, the AH Series draws design inspiration from the iconic Mori Seiki lathes of the 1980s.

Each of the two AH models is equipped with a powerful 60 HP spindle supported by dual double-row roller bearings for superior radial load handling and angular contact bearings for axial stability. This configuration delivers impressive torque — up to 3,154 lbs./ft. at just 100 RPM. A 3-speed geared head, paired with an oil chiller unit, ensures consistent thermal stability during prolonged operation. Additionally, the coolant tank is isolated from the machine base, preventing heat transfer to the casting and simplifying cleaning and maintenance.

The 55° inclined cross slides not only enhance operator access but also increase the mass and rigidity of the saddle assembly. Both X and Z axes use widely spaced box ways with hand-scraped mating surfaces coated with Turcite-B for low-friction, long-life performance. Large 2.5″ (63.5 mm) diameter precision ballscrews in the Z-axis, driven by high-torque Fanuc servo motors, provide exceptional thrust for demanding turning, boring, and drilling tasks.

A heavy-duty 12-station turret, hydraulically actuated and clamped, includes a 6.5″ (165 mm) thick tool disk capable of holding 1.25″ (31.75 mm) square-shank turning tools and boring bars up to 3″ (76.2 mm) in diameter.

Specifications

| Item / Model |

AH-06

Request a Quote |

AH-09

Request a Quote |

|---|---|---|

|

Capacities | ||

|

Swing over Bed/Front Cover |

37.4″ |

37.4″ |

|

Maximum Turning Diameter |

35.4″ |

35.4″ |

|

Swing over Carriage |

29.5″ |

29.5″ |

|

Maximum Cross Travel (X axis) |

-1.77”, + 17.8″ |

-1.77”, + 17.8″ |

|

Maximum Longitudinal Travel (Z axis) |

40.5″ (60”, 80”, 119”, 158” opt.) |

40.5″ (60”, 80”, 119”, 158” opt.) |

|

Distance between Centers |

45.4″ (65”, 85”, 124”, 163” opt.) |

45.4″ (65”, 85”, 124”, 163” opt.) |

|

Spindle | ||

|

Spindle Motor |

60 HP |

60 HP |

|

Spindle Nose |

A2-15 |

A2-15 |

|

Spindle RPM |

0 – 1200 RPM |

0 – 800 RPM |

|

Hole through Spindle |

6.57″ |

9.05″ |

|

Bar Capacity |

6.02” |

8.05″ |

|

Spindle Bearing Diameter |

8.66” |

11.02″ |

|

Spindle Inside Taper |

M.T. 7 |

M.T. 7 |

|

Hydraulic Chuck |

24” 3-Jaw |

24” 3-Jaw |

|

Turret | ||

|

Turret Tool Positions |

12 |

12 |

|

Turret Type |

Hydraulic clamp / index |

Hydraulic clamp / index |

|

Tool Mounting |

Block type |

Block type |

|

O.D. Tool Shank Size |

1.25” |

1.25” |

|

I.D. Tool Shank Size |

3.0” |

3.0” |

|

Index Time |

.8 Seconds |

.8 Seconds |

|

Tailstock | ||

|

Quill Diameter of Tailstock |

5.7″ |

5.7″ |

|

Quill Stroke of Tailstock |

3.94″ |

3.95″ |

|

Quill Taper of Tailstock |

M.T. 5 |

M.T. 5 |

|

Tailstock Body Travel |

37.4” |

37.4″ |

|

Ballscrews and Axis Motors | ||

|

Z Axis Ballscrew Diameter |

63mm (2.48”) x 12 Pitch |

63mm (2.48”) x 12 Pitch |

|

X Axis Ballscrew Diameter |

40mm (1.57”) x 10 Pitch |

40mm (1.57”) x 10 Pitch |

|

Ballscrew Type |

Class 3 Double Nut Pre-Loaded |

Class 3 Double Nut Pre-Loaded |

|

Ballscrew Mounting Type |

Pre-Tensioned |

Pre-Tensioned |

|

X-Z Servo Motor HP |

X = 9.0 HP / Z = 12.0 HP |

X = 9.0 HP / Z = 12.0 HP |

|

Feeds | ||

|

Rapid Traverse Rate X,Z |

472, 590 IPM |

472, 590 IPM |

|

Cutting Feed Rate |

0.01 – 315 IPM |

0.01 – 315 IPM |

|

Positioning Accuracy |

± .0003″ Full Stroke |

± .0003″ Full Stroke |

|

Repeatability |

± .0002″ |

± .0002″ |

|

General | ||

|

Hydraulic Pump Motor |

7.5 HP |

7.5 HP |

|

Coolant Tank Capacity |

100 Gallons |

100 Gallons |

|

Coolant Pump Motor |

1.7 HP |

1.7 HP |

|

Floor Space |

233″ x 94″ x 106″ |

233″ x 94″ x 106″ |

|

Machine Power Source |

208/220 Volts, 3 Phase, 225 Amps |

208/220 Volts, 3 Phase, 225 Amps |

|

Machine Weight (40” bed) |

35,200 lbs. |

35,200 lbs. |