QuickTECH i-Ultimate Series 10-Axis Twin Spindle Mill-Turn Centers with Dual B-Axes

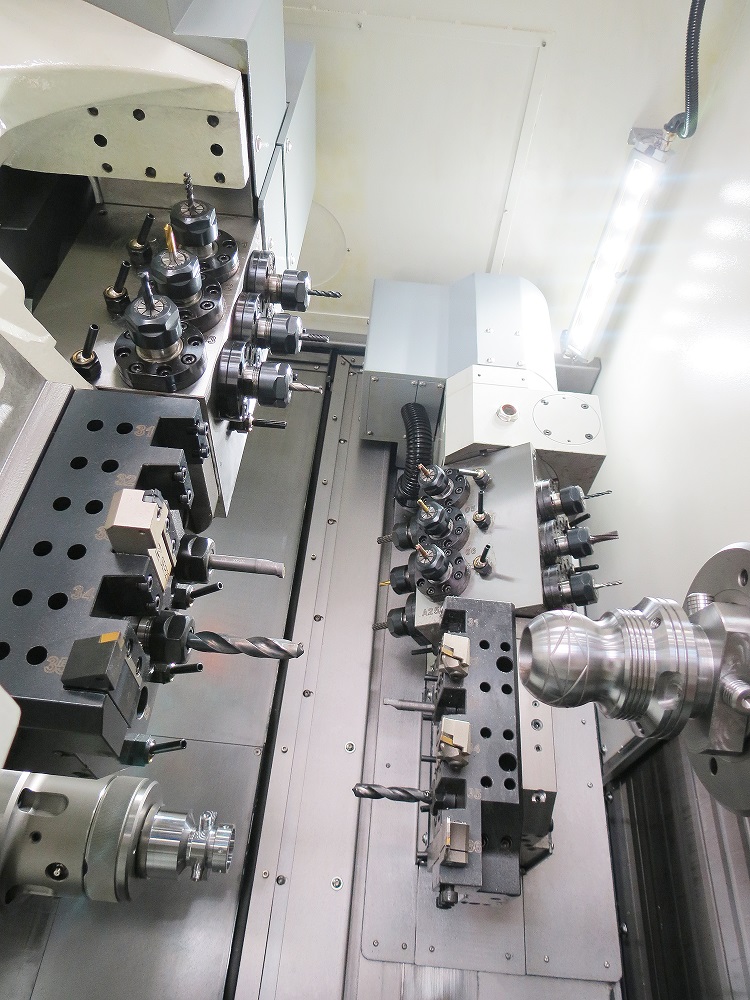

The QuickTECH i-Ultimate Series 10-axis mill-turn centers represent the pinnacle of multi-tasking CNC technology. Featuring dual B-axes and twin opposing spindles, these advanced machines deliver complete “done-in-one” part production with minimal operator intervention. Designed for manufacturers demanding maximum flexibility, speed, and accuracy, the i-Ultimate Series performs simultaneous 5-axis milling and turning operations on both spindles within a compact footprint.

Engineered for aerospace, medical, automotive, and precision component manufacturers, the i-Ultimate Series excels at machining parts with compound angles, intersecting geometries, and intricate features — all completed in a single setup. Its dual B-axes and twin spindles make it ideal for parts that traditionally require multiple operations across several machines, such as turbine components, implants, and housings demanding tight tolerances and ultra-fine surface finishes.

Competing directly with multi-axis solutions from Haas, Doosan, DMG Mori, and Mazak, the QuickTECH i-Ultimate Series delivers unmatched performance and versatility at a significantly lower cost of ownership.

Key Features

- Optional Automation Packages – Easily integrates with bar feeders, part conveyors, or robotic loading systems for continuous unattended machining.

- 10-Axis Twin-Spindle Mill-Turn Configuration – Simultaneous machining on both spindles with full 5-axis contouring for complex geometries.

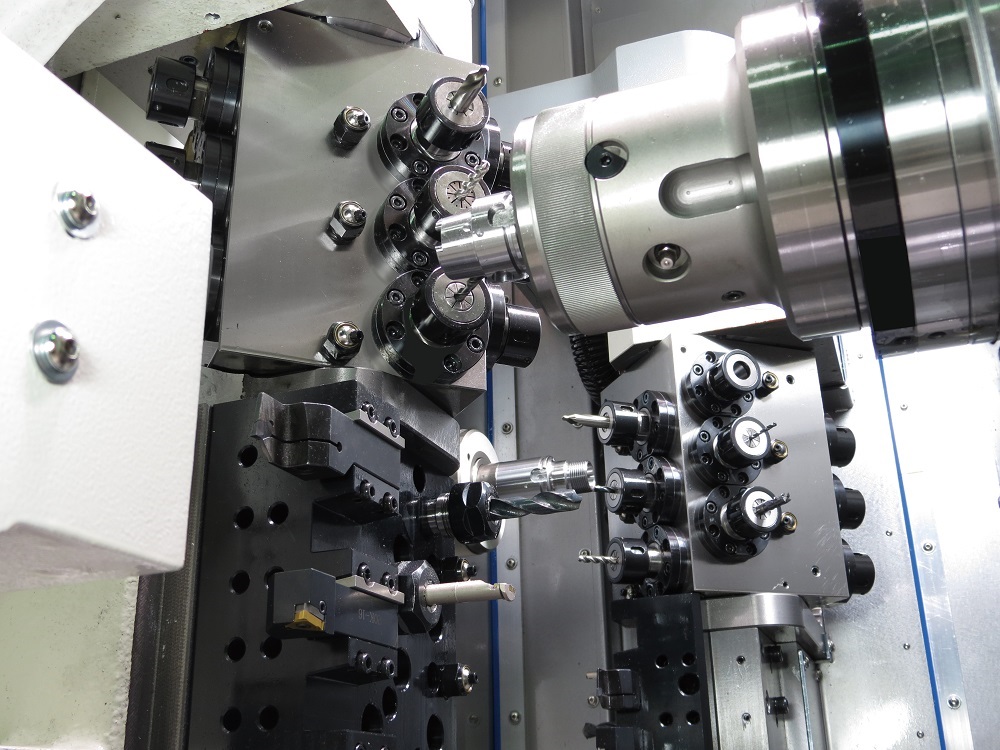

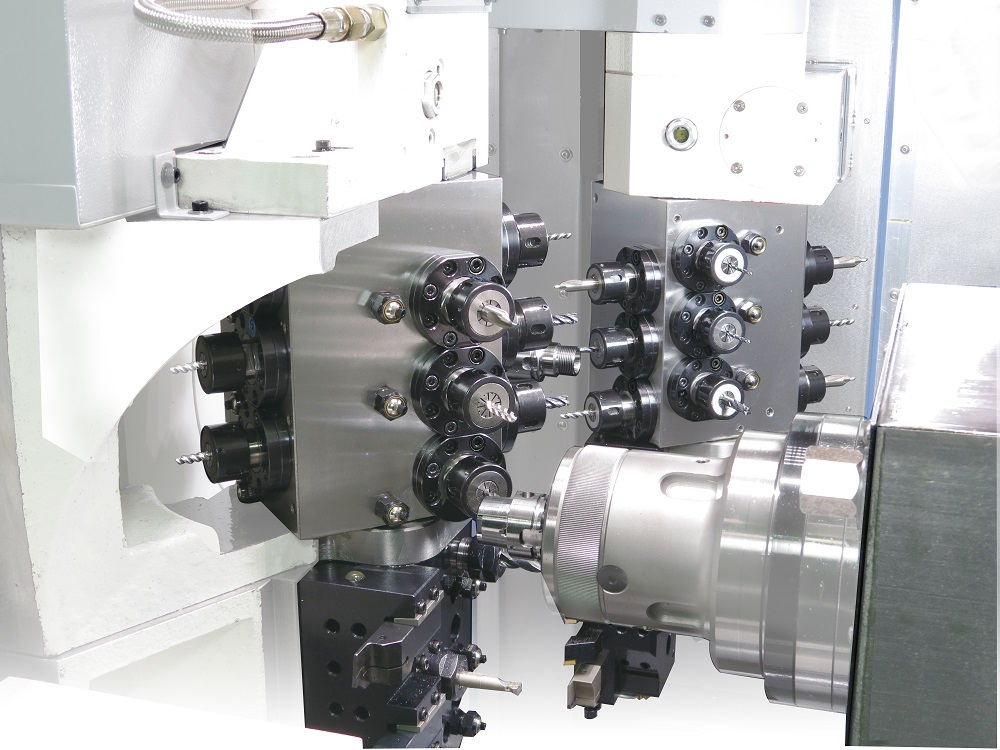

- Dual B-Axes – Independently controlled tilting heads perform multi-face machining in a single setup, reducing fixturing and handling time.

- 56-Tool Capacity – Generous tooling system combines live milling tools and turning tools to handle a wide range of operations without manual changeovers.

- High-Rigidity Gantry Structure – Compact, heavy-duty casting absorbs vibration and maintains dimensional accuracy during heavy or high-speed cutting.

- Precision Linear Guideways & Dual Ball Screws – Deliver smooth axis motion, superior positioning accuracy, and long-term repeatability.

- Advanced Coolant & Chip Evacuation System – Keeps the cutting area clean and thermally stable to preserve tool life and surface integrity.

- Compact Fully Enclosed Design – Minimizes floor space while improving safety, chip management, and automation integration.

Specifications

| Item / Model |

i-42

Request a Quote

|

i-60

Request a Quote

|

|---|---|---|

|

Main Spindle Capacity |

||

|

Max Bar Working Capacity |

1.65″ |

2.36″ |

|

Max Turning Length |

9.8″ |

9.8″ |

|

Spindle Speed Range (std.) |

6,000 RPM |

4,000 RPM |

|

Spindle Motor |

15 HP |

15 HP |

|

C-Axis Increment |

.001° |

.001° |

|

Sub-Spindle Capacity |

||

|

Max Bar Working Capacity |

1.65″ |

1.65″ |

|

Max Turning Length |

3.94″ |

3.94″ |

|

Spindle Speed Range |

6,000 RPM |

6,000 RPM |

|

Spindle Motor |

7.5 HP Integral Motor |

7.5 HP Integral Motor |

|

C-Axis Increment |

.001° |

.001° |

|

Travel and Feed |

||

|

Rapid Traverse Rate |

1,181″/min. |

1,181″/min. |

|

Tooling System (Main) |

||

|

Tooling Type |

Gang Tool / Servo Y-Axis / KM-25 Quick Change |

Gang Tool / Servo Y-Axis / KM-25 Quick Change |

|

Number of Turning Tools |

6 O.D. (5 + 1 cut-off) & 5 I.D. |

6 O.D. (5 + 1 cut-off) & 5 I.D. |

|

Square Shank Size |

.75″ (20mm) |

.75″ (20mm) |

|

Boring Bar Capacity |

.75″ (ED-20) |

.75″ (ED-20) |

|

B-Axis |

360° |

360° |

|

B-Axis Index Time |

.3 Seconds 90° / .6 Seconds 360° |

.3 Seconds 90° / .6 Seconds 360° |

|

Number of Live Tools |

12 |

12 |

|

Live Tool Spindle Motor |

2 HP |

2 HP |

|

Live Tool Spindle Speed |

4,000 |

4,000 |

|

Live Tool Shank |

ER-20 Collet |

ER-20 Collet |

|

Tooling System (Sub) |

||

|

Tooling Type |

Gang Tool / Servo Y-Axis / KM-25 Quick Change |

Gang Tool / Servo Y-Axis / KM-25 Quick Change |

|

Number of Turning Tools |

5 O.D. & 9 I.D. |

5 O.D. & 9 I.D. |

|

Square Shank Size |

.75″ (20mm) |

.75″ (20mm) |

|

Boring Bar Capacity |

.75″ (ER-20) |

.75″ (ER-20) |

|

B-Axis |

360° |

360° |

|

B-Axis Index Time |

.3 Seconds 90° / 6 Seconds 360° |

.3 Seconds 90° / 6 Seconds 360° |

|

Number of Live Tools |

12 |

12 |

|

Live Tool Spindle Motor |

2 HP |

2 HP |

|

Live Tool Spindle Speed |

4,000 |

4,000 |

|

Live Tool Shank |

ER-20 Collet |

ER-20 Collet |

|

General |

||

|

CNC Control |

Mitsubishi M830S |

Mitsubishi M830S |

|

Machine Dimensions with Chip Conveyor |

138″ x 75″ x 75″ |

138″ x 75″ x 75″ |

|

Machine Weight |

9,240 lbs. |

9,240 lbs. |